Air blowing device for mold forming part

A technology of mold forming and blowing device, applied in the field of blowing device, can solve the problems of inability to meet industrial requirements, unsatisfactory product quality, drag on product surface, etc., and achieve the effects of simple structure, avoidance of drag and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be further described with reference to the accompanying drawings and specific embodiments, so as to facilitate a clearer understanding of the technical idea claimed by the present invention.

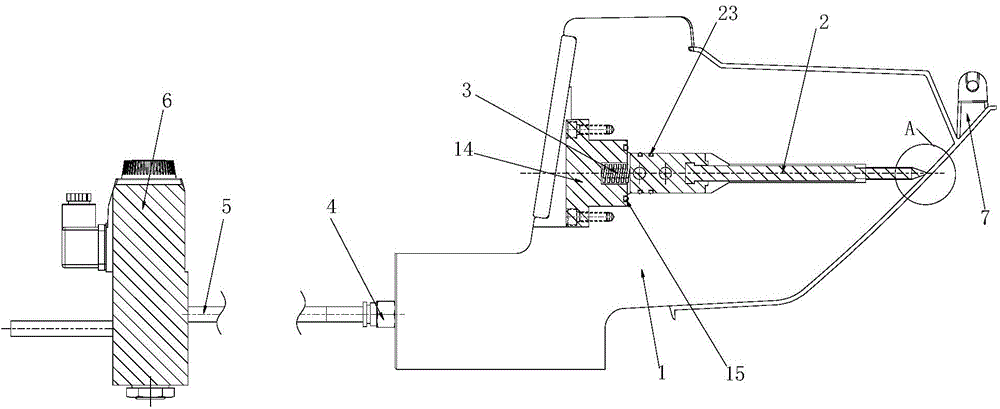

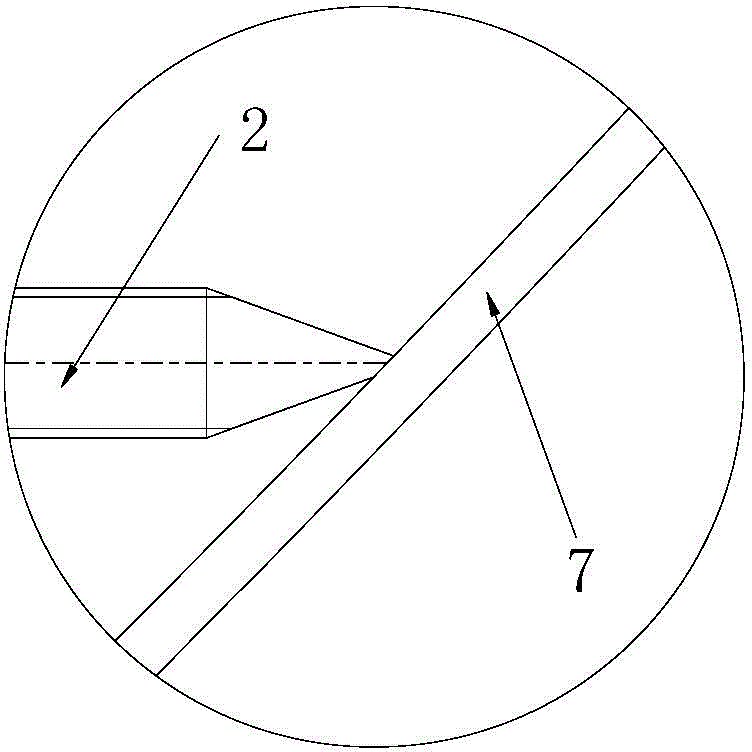

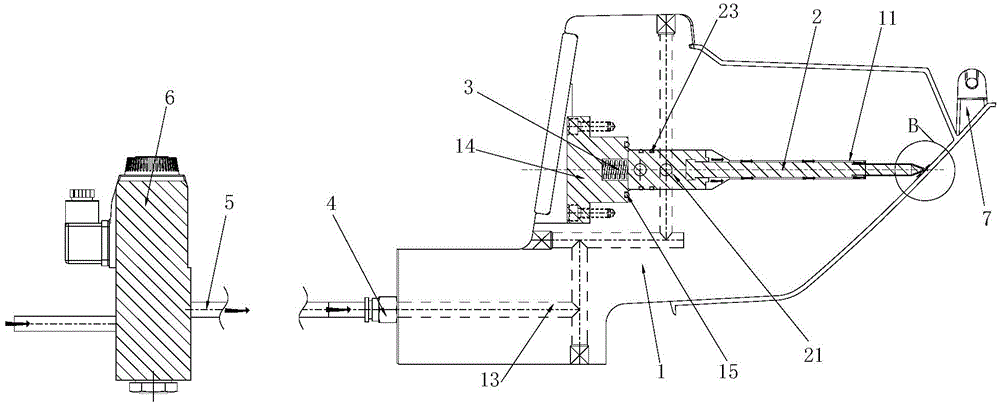

[0022] like Figure 1-5 As shown, it is an air blowing device for a mold forming part of the present invention, comprising a forming part 1 and a movable air needle 2; the forming part 1 is provided with a ventilation channel 11 for introducing gas, The front end penetrates the molding surface of the molded part 1 and forms the air outlet 12; the movable air needle 2 is movably installed in the ventilation channel 11 and can be in the closed position to block the air outlet 12 to close the air outlet 12 and to open the air outlet 12 In order to allow the gas in the ventilation channel 11 to move between the open positions of the gas outlet through the gas outlet 12 toward the outside.

[0023] In the process of mold clamping and injection m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com