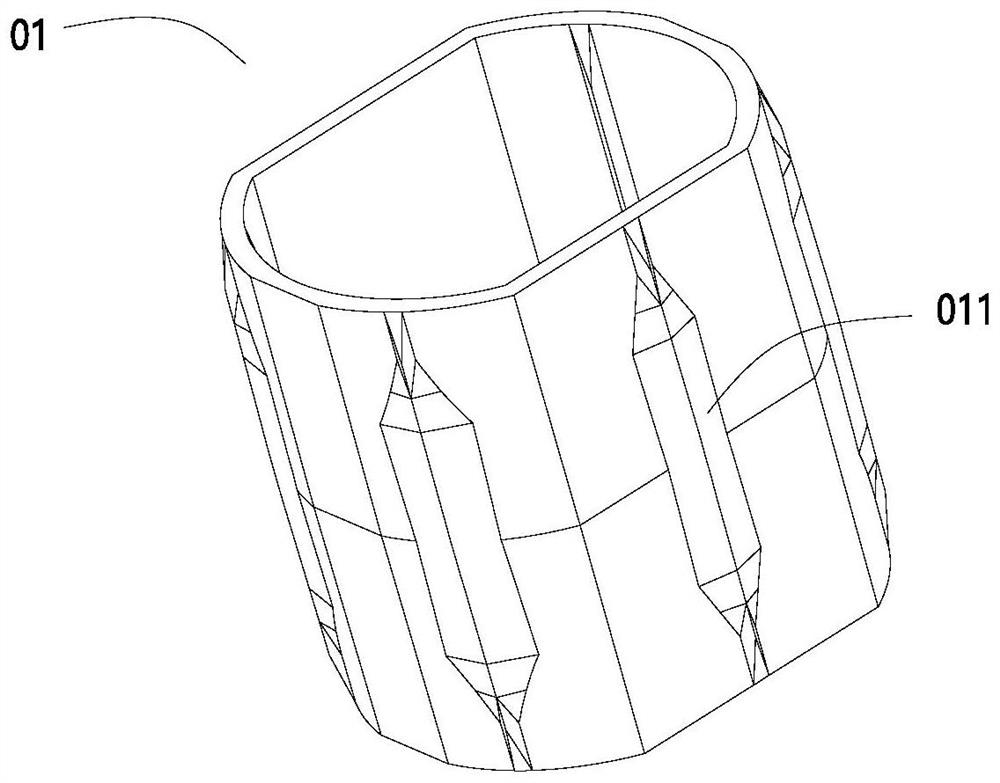

Injection mold for automobile thin-wall cylindrical part and ejection method

A technology for injection molds and cylindrical parts, which is used in the fields of injection molds and ejection of thin-walled cylindrical parts of automobiles, can solve problems such as product deformation and fracture, and achieve the effect of avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

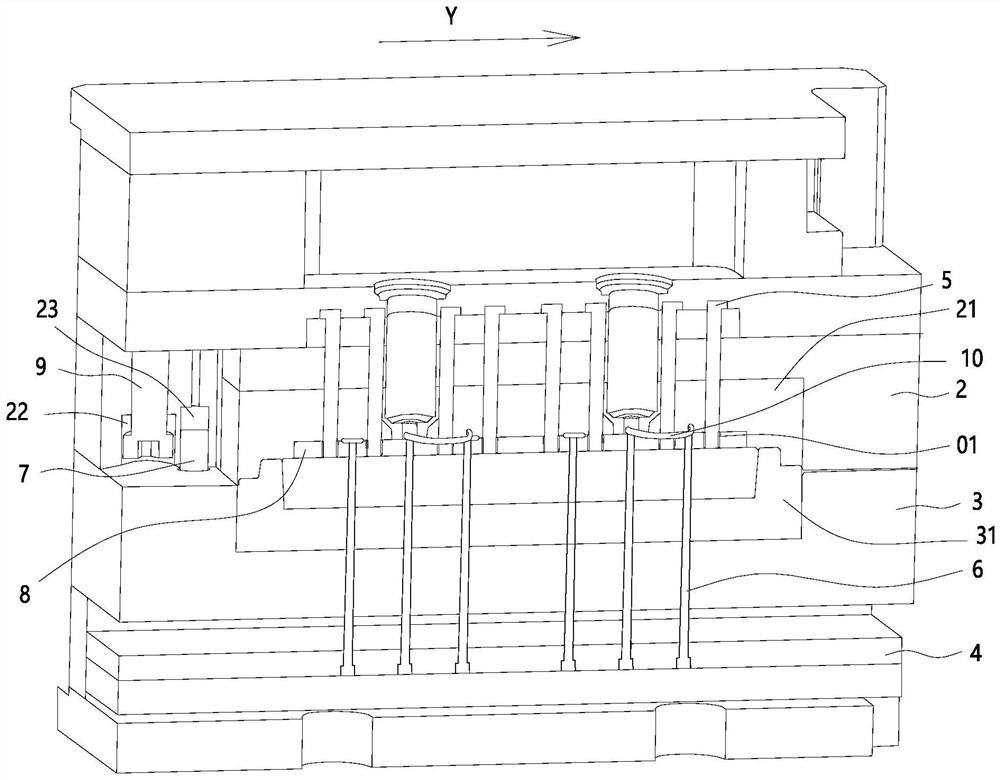

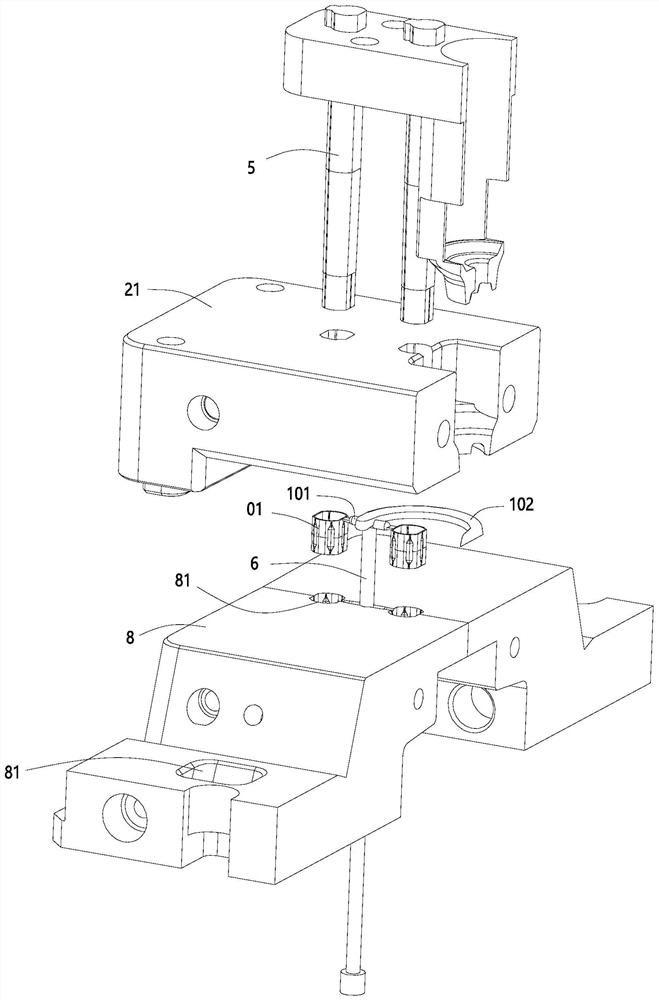

[0033] In order to set forth the present invention better, below with reference to appended Figure 1-3 The present invention is further described in detail.

[0034] As a specific embodiment of the present invention, such as figure 2 Shown, a kind of injection mold of automobile thin-walled cylindrical part, comprises:

[0035] The nozzle plate 1, the front template 2, the rear template 3 and the rear ejector plate 4 are arranged in sequence;

[0036] The nozzle plate 1 is provided with a core-pulling rod 5, and the core-pulling rod 5 is used to form the inner wall of the thin-walled cylindrical part of the automobile;

[0037] The front template 2 is provided with a front mold core 21, and the front mold core is provided with a runner groove (not shown in the figure);

[0038] The rear template 3 is provided with a rear mold core 31 and a slide block 8, the slide block 8 is provided with a semicircular arc groove 82, and the two slide blocks 8 are arranged opposite to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com