Autorotation preventing VCM structure

An anti-rotation and anti-rotation block technology is applied in the direction of the casing/cover/support, electrical components, electromechanical devices, etc. It can solve problems such as focusing failure, irreversible deformation of shrapnel, impact of voice coil motor, etc., to prevent carrier rotation, The internal structure is compact and the effect of preventing the deformation of the shrapnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

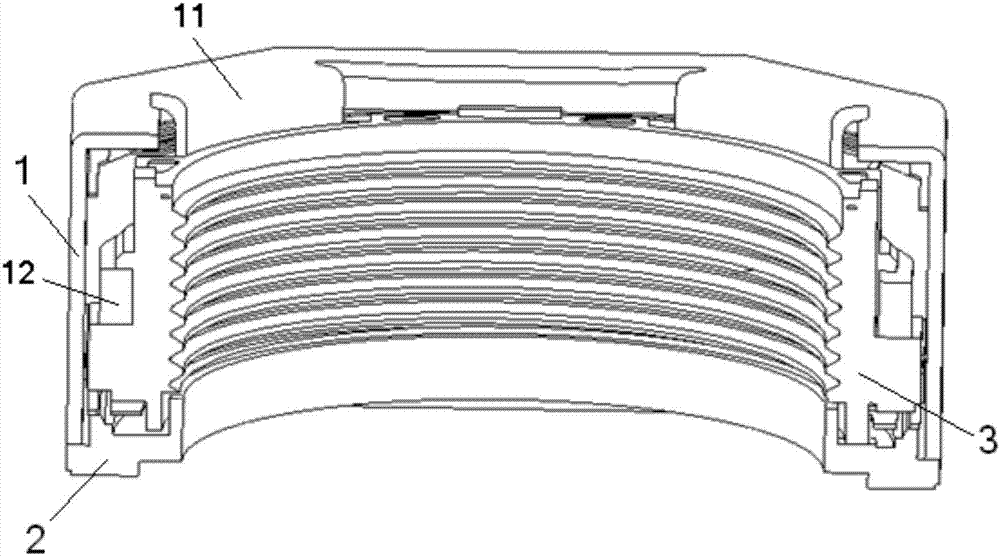

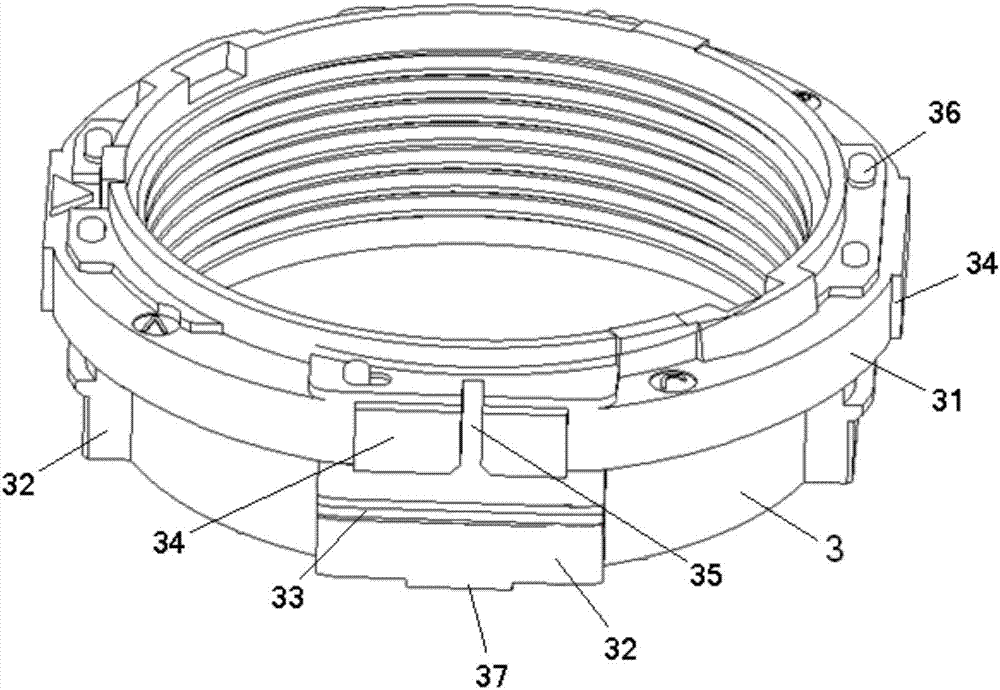

[0016] Such as figure 1 As shown, an anti-rotation VCM structure includes: an outer shell 1, a base body 2, and a carrier 3. The top opening of the outer shell 1 is provided with a downwardly bent inner claw 11, and the inner wall of the outer shell 1 A stopper 12 is vertically arranged on the top; the carrier 3 is arranged in a cylindrical structure, and the outer wall below the carrier 3 is provided with a first boss 31 for a week, and the outer wall from the first boss 31 to the opening above the carrier 3 is evenly provided with A plurality of second bosses 32, the top of the second boss 32 is flush with the upper opening of the carrier 3, the bottom of the second boss 32 is in contact with the top surface of the first boss 31, and the side wall of the second boss 32 A coil retaining wall 33 is arranged on it, the thickness of the second boss 32 matches the thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com