Truck tire tread and truck tire

A tire tread, tread technology, applied in tire tread/tread pattern, heavy-duty tires, tire parts, etc., can solve problems such as unusable tires, unsightly wear patterns on steering wheels, and irregular wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to embodiments of the invention, an example of which is illustrated in the accompanying drawings. This example is provided by way of explanation of the invention.

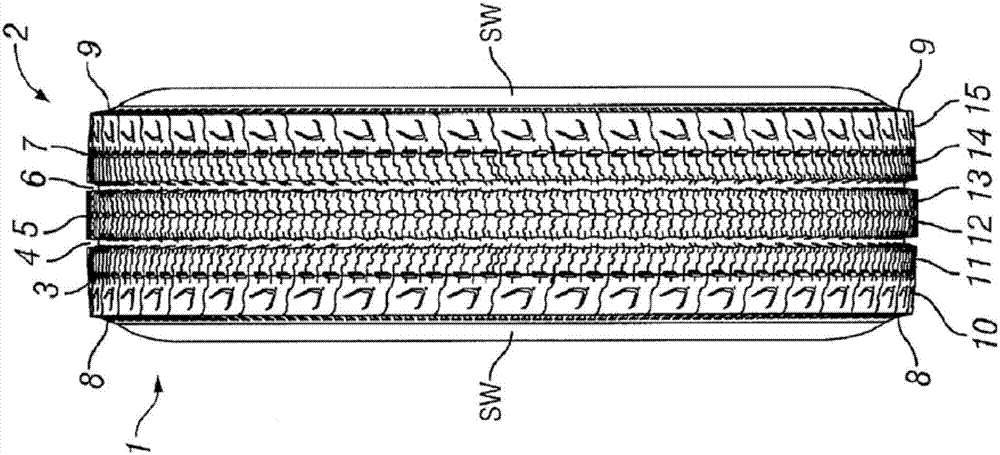

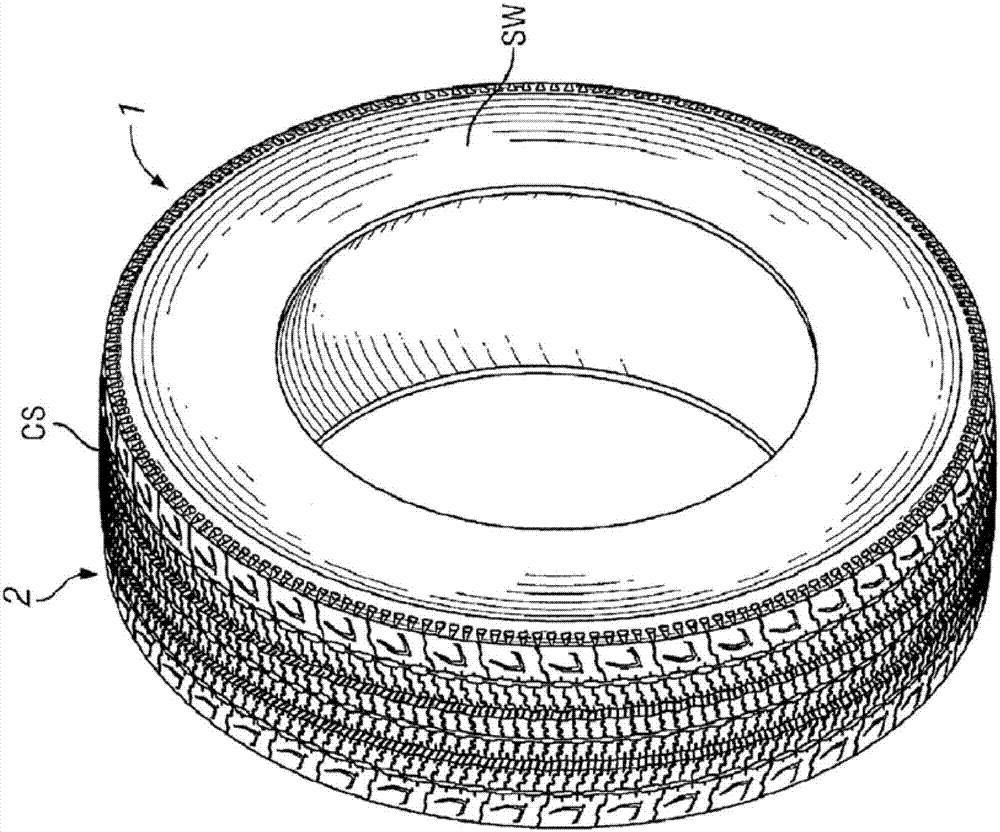

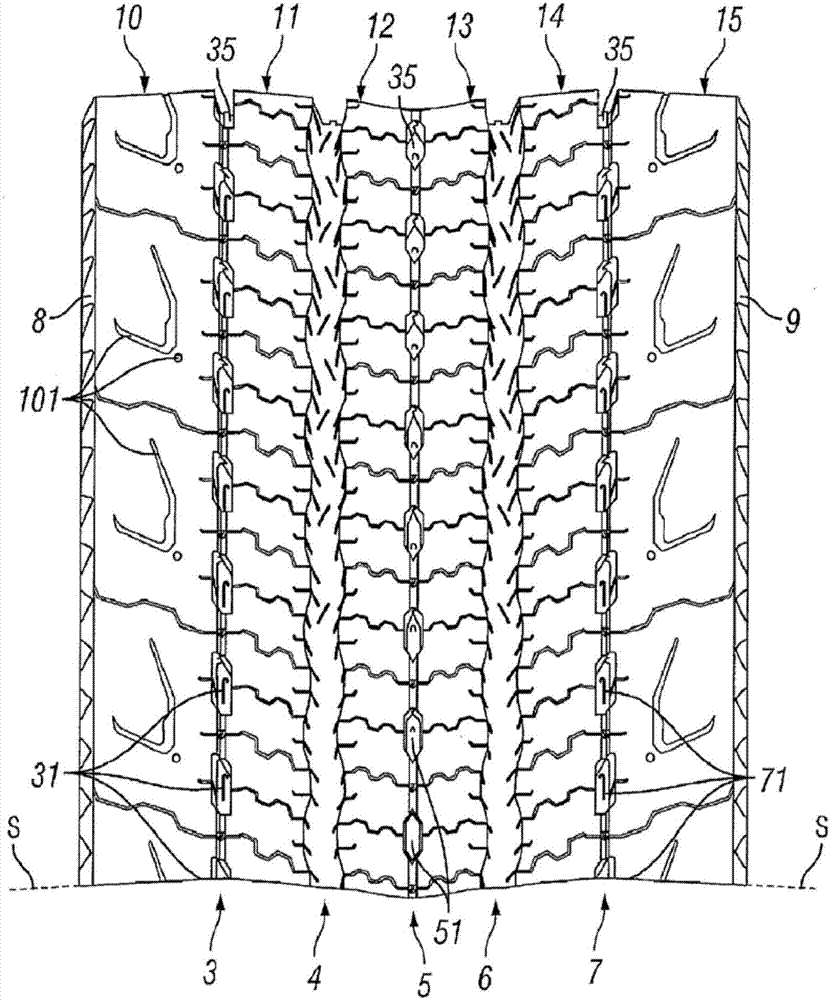

[0028] Such as figure 1 with figure 2 As shown in , a heavy truck tire 1 comprises a tread 2 according to an embodiment of the invention. The tread 2 has five longitudinal grooves 3 , 4 , 5 , 6 and 7 continuous around the circumference of the tyre. Between the tread shoulders 8 and 9 , five longitudinal grooves delimit six ribs 10 , 11 , 12 , 13 , 14 and 15 .

[0029] The grooves 3 and 7 closest to the tread shoulders will now be referred to as "shoulder grooves". The groove 5 located in the center of the tread will now be called "central groove". The grooves 4 and 6 located between the central groove and the shoulder grooves will now be referred to as "intermediate grooves".

[0030] The ribs 10 and 15 between the shoulders and the shoulder grooves will now be ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com