Lifting mechanism of aviation airborne electric crane

A technology of lifting mechanism and electric crane, which is applied in the direction of clockwork mechanism and hoisting device, which can solve the problems of unsatisfactory multi-frequency lifting and hoisting of goods, looseness, and disorderly turns of steel wire ropes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

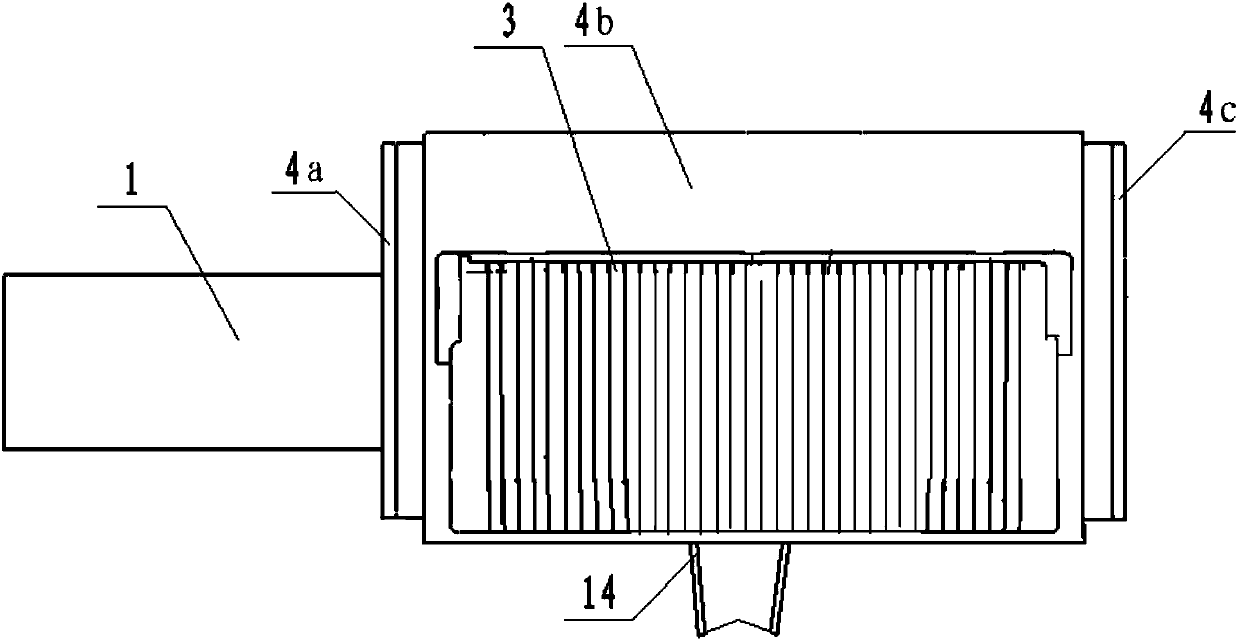

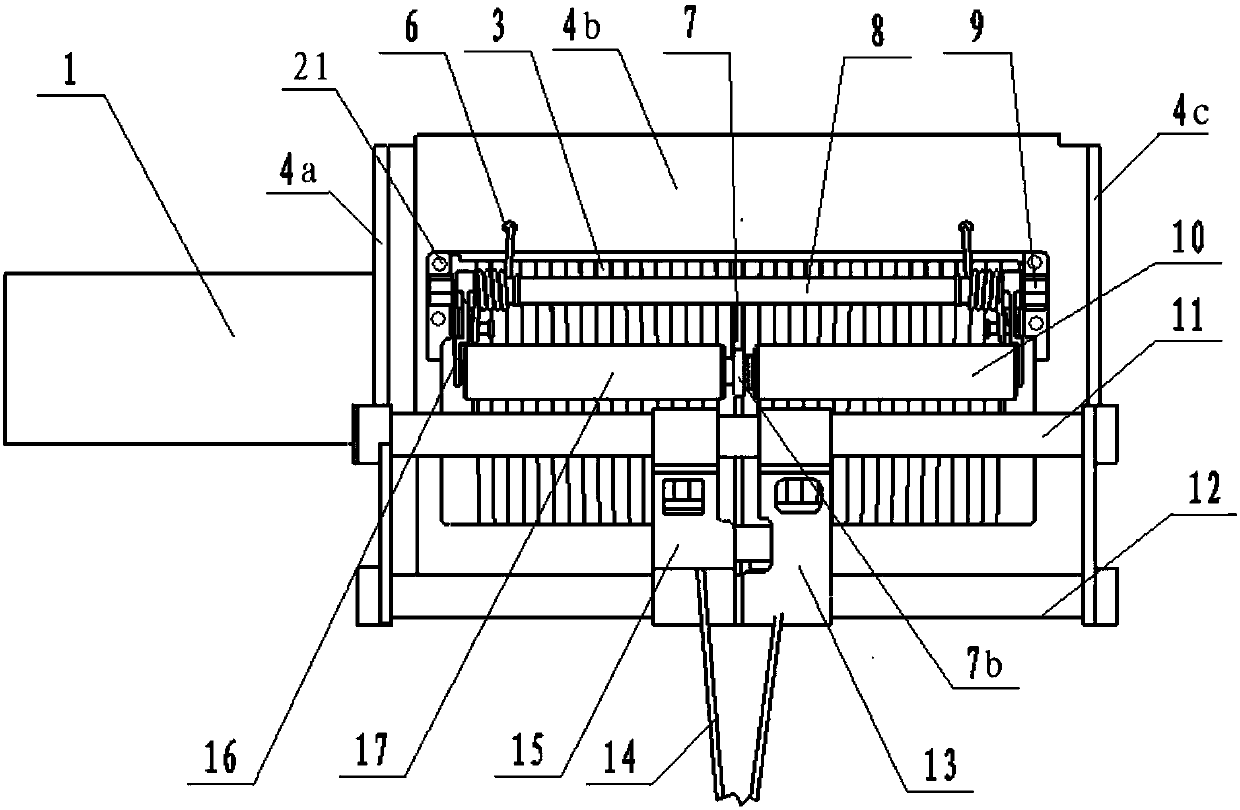

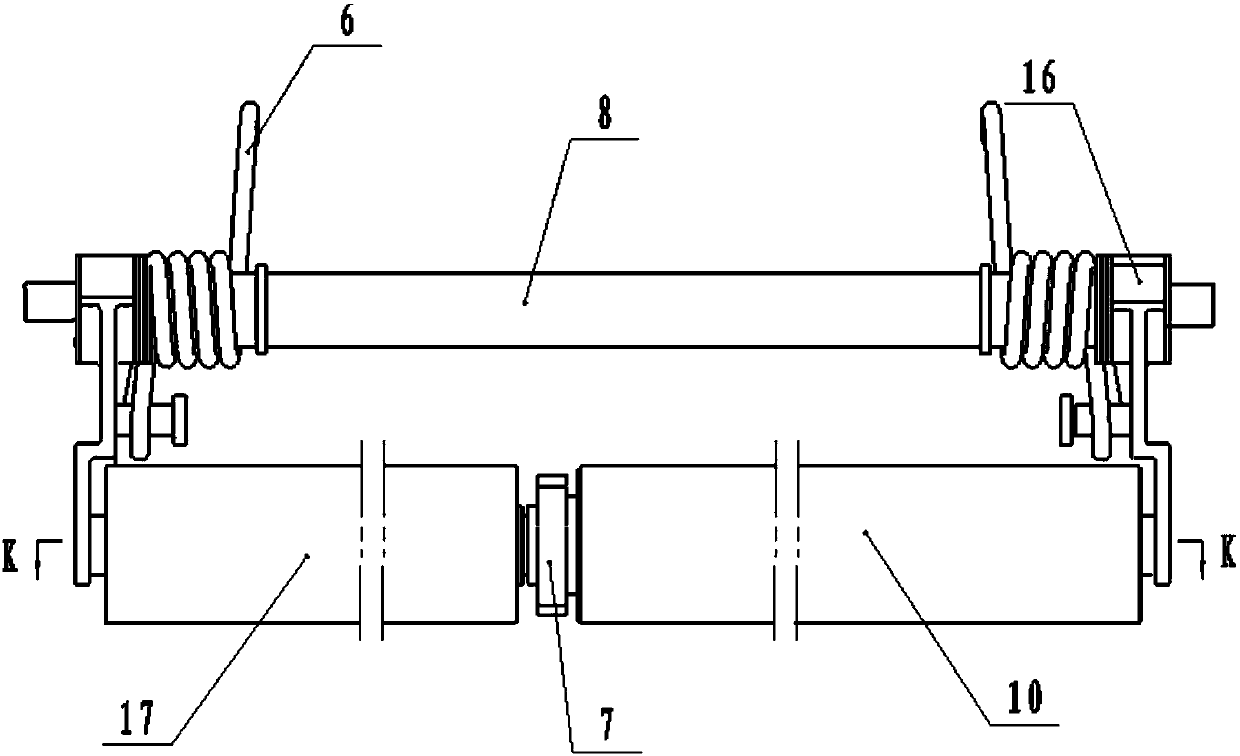

[0013] The present invention will be described in further detail below. see Figure 2 to Figure 4 , an aviation airborne electric crane lifting mechanism, comprising a drive motor assembly 1, a reel assembly 3, a crane lifting mechanism housing and a steel wire rope 14; the crane lifting mechanism housing includes a left end cover 4a, a cylinder 4b and a right end cover 4c, through Screws fix the left end cover 4a on the left port of the cylinder body 4b, and fix the right end cover 4c on the right port of the cylinder body 4b, and a rectangular window for storing the wire rope 14 is opened on the cylinder body 4b; the reel assembly 3 includes Drum shaft, left drum and right drum, the left drum and right drum are installed in the crane shell through the drum shaft, the left drum has a left-handed helical groove for accommodating wire ropes, and the right drum has a right-handed helical groove for accommodating wire ropes. The motor assembly 1 is fixed on the left end cover 4a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com