Underbody structure of automobile

A car body and automobile technology, applied in the direction of substructure, superstructure, vehicle parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] An embodiment of the present invention will be described in detail below based on the drawings.

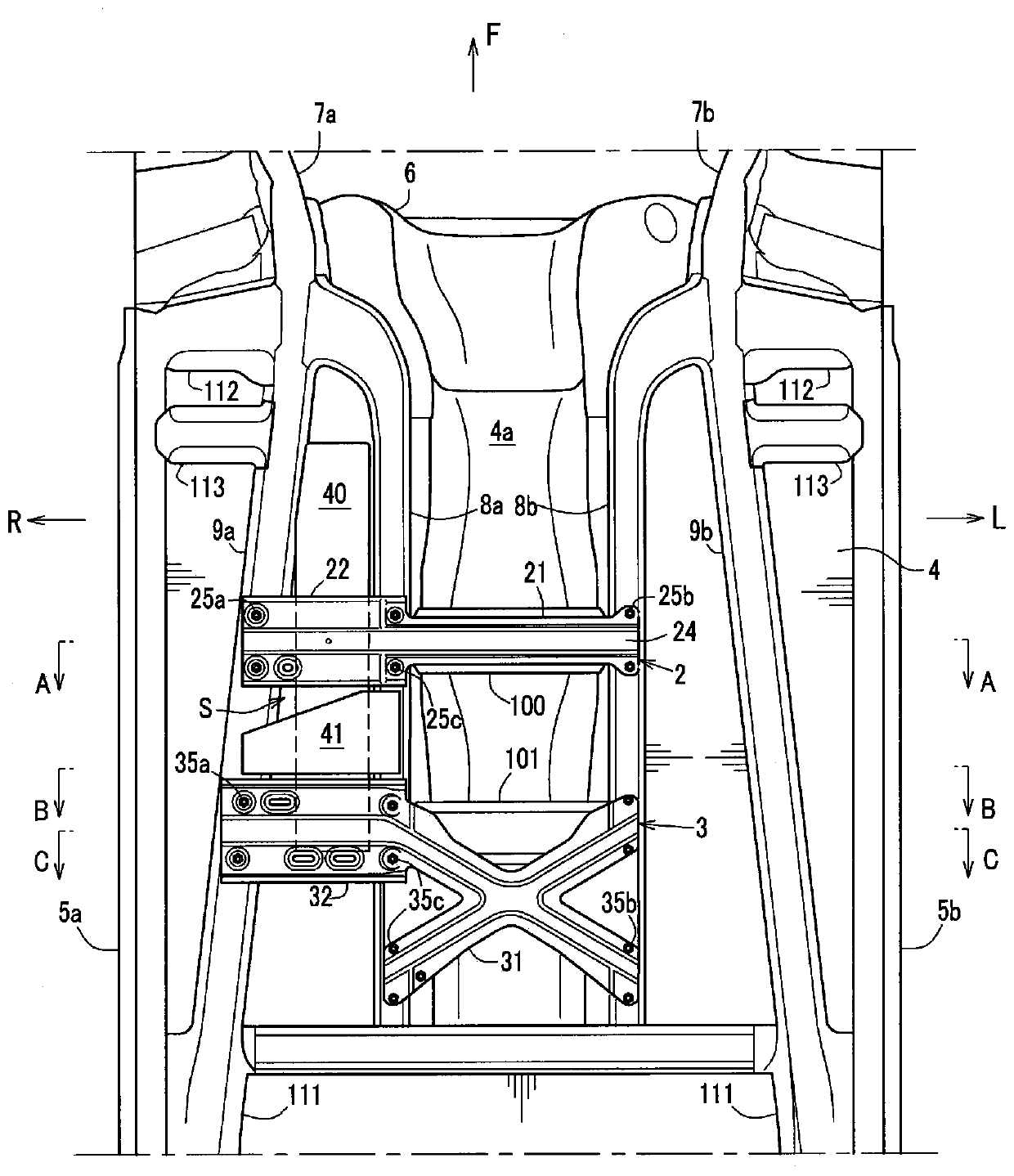

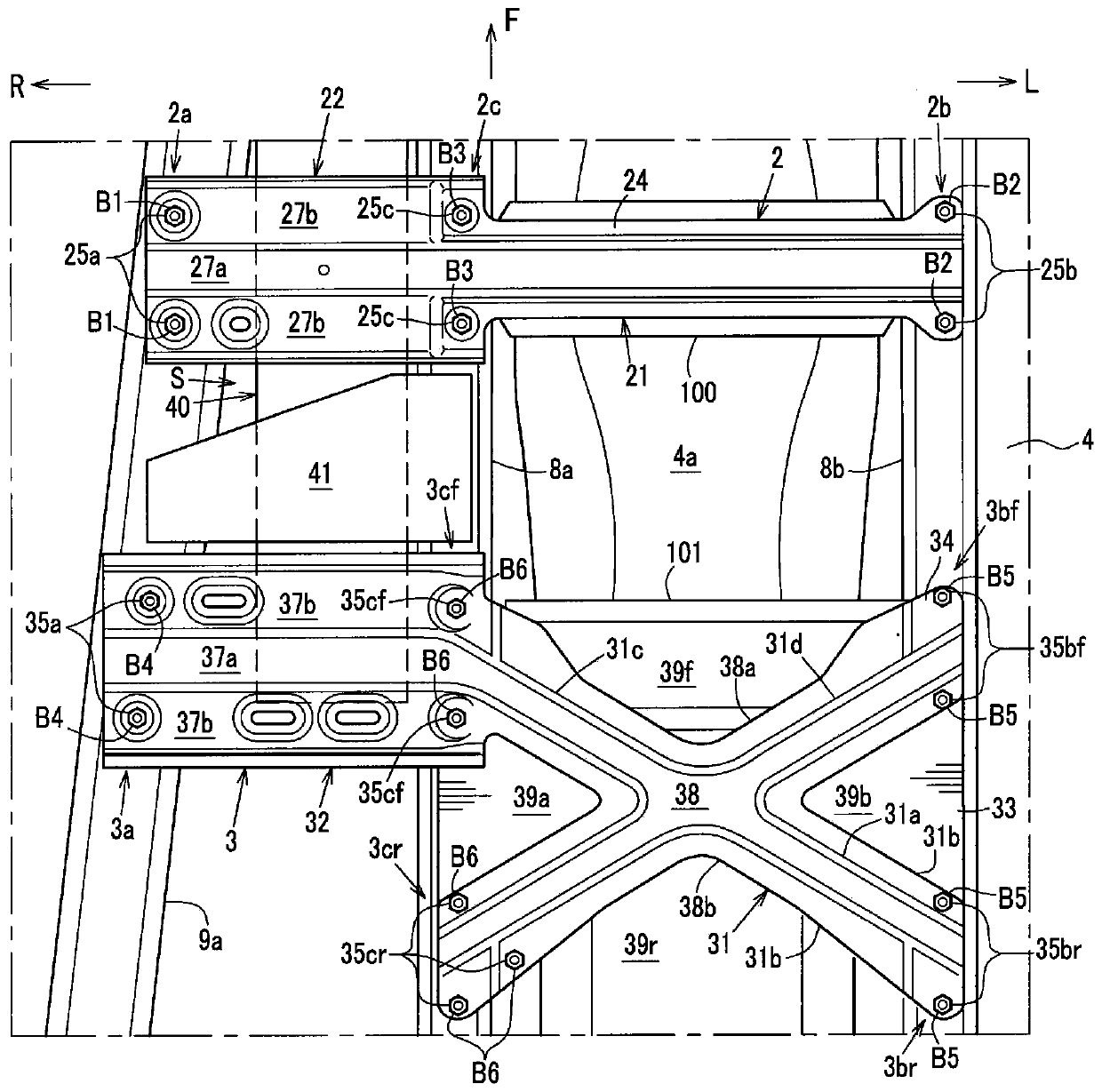

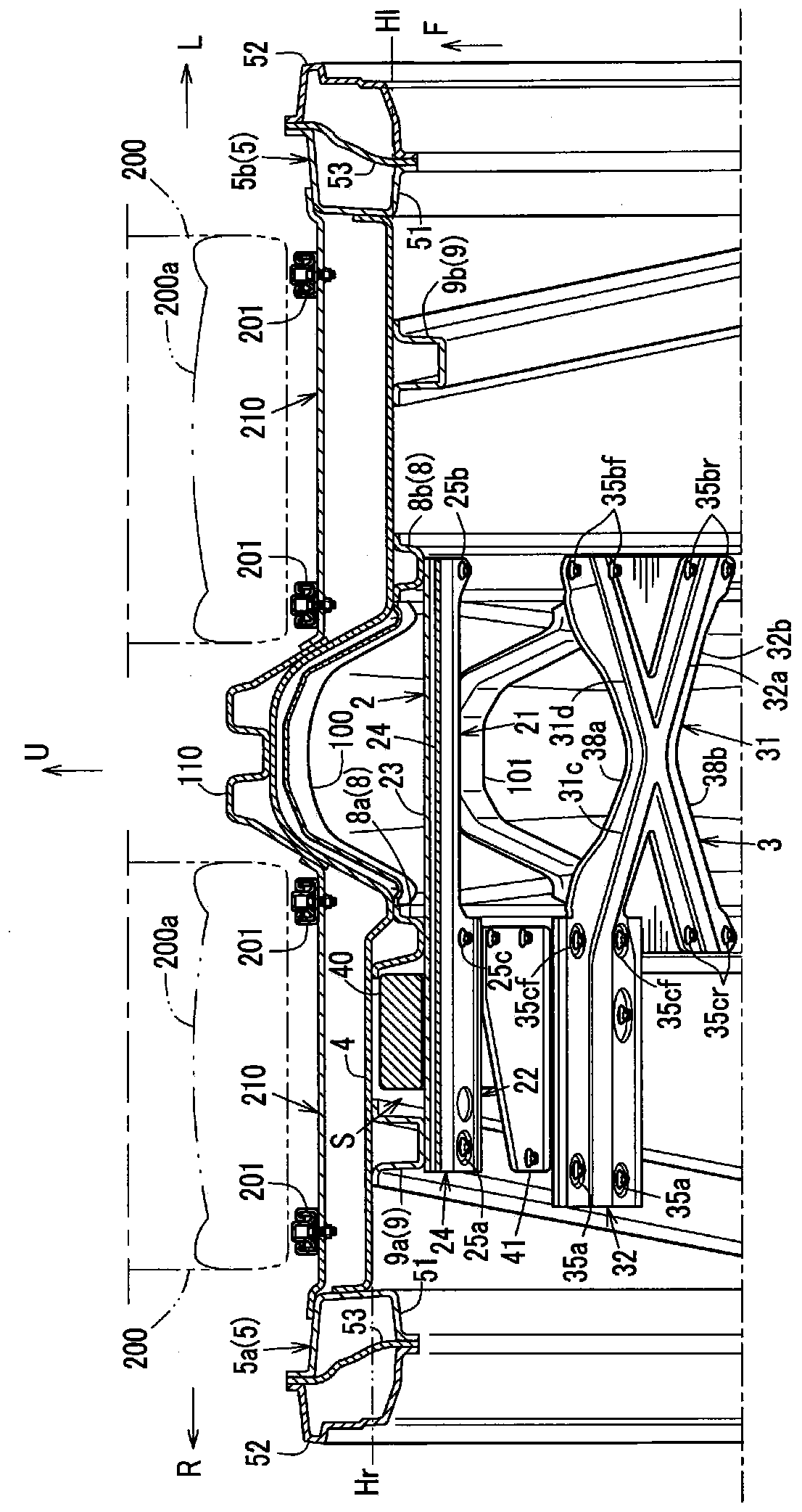

[0033] figure 1 is a bottom view of the lower body structure of the automobile of this embodiment, figure 2 yes figure 1 The main part of the enlarged figure, image 3 viewed from above figure 1 A three-dimensional cross-sectional view of the main part of the A-A line, Figure 4 It is a longitudinal sectional view showing the main part of the central part in the width direction of the channel part, Figure 5 (a) is viewed from obliquely above figure 1 The three-dimensional cross-sectional view of the main part of the B-B line in, Figure 5 (b) is figure 1 A cross-sectional view of the main part of the C-C line, Image 6 (a) is a perspective view of the upper side panel of the front side underfloor beam viewed obliquely from above in front, Image 6 (b) is with Image 6 An enlarged sectional view of the beam under the front floor corresponding to line D-D in (a), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com