Large-scale bolt rotation angle monitoring system and method based on passive RFID

A technology of rotation angle and monitoring system, applied in measuring devices, instruments, electrical devices, etc., can solve the problems that the system cannot automatically alarm, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

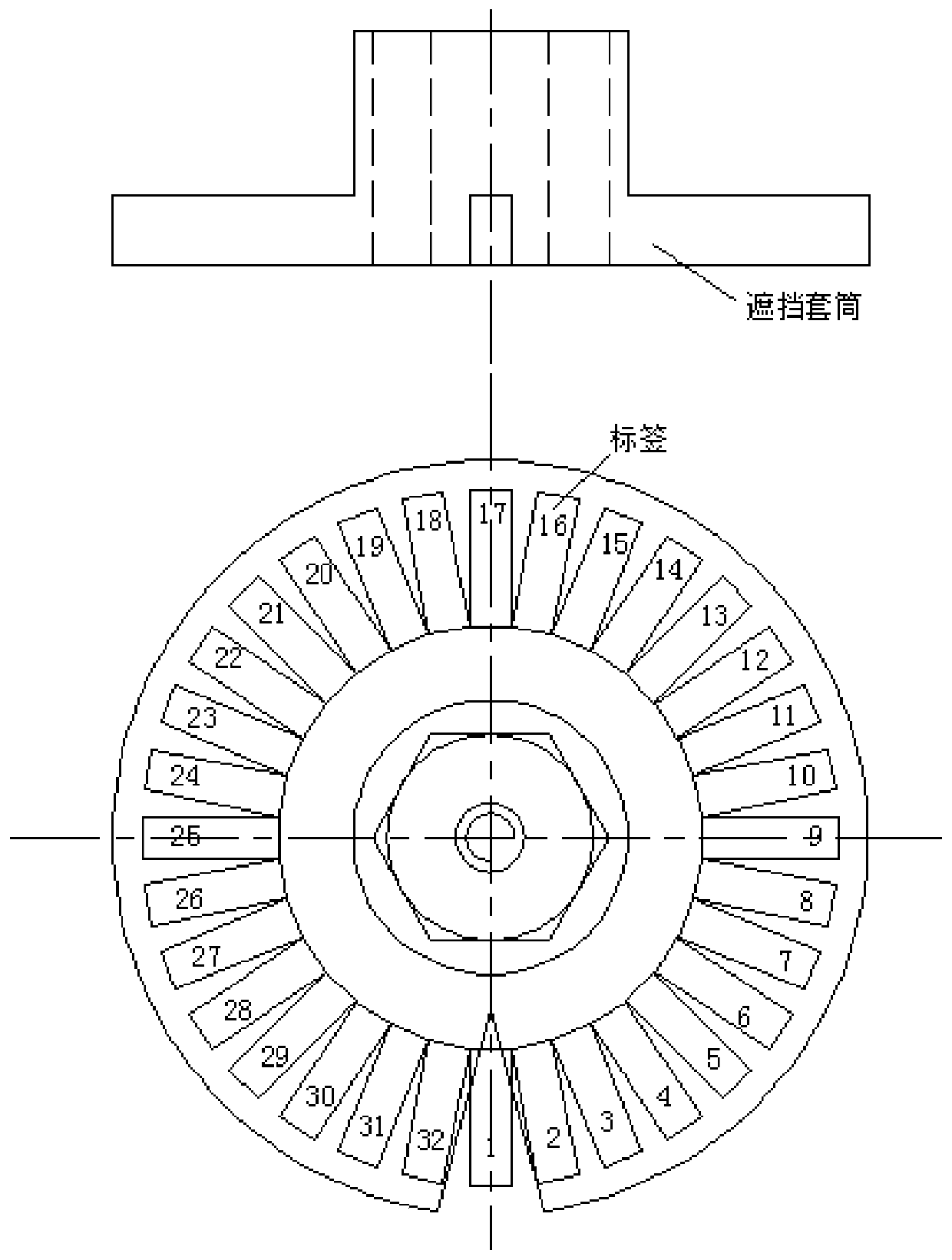

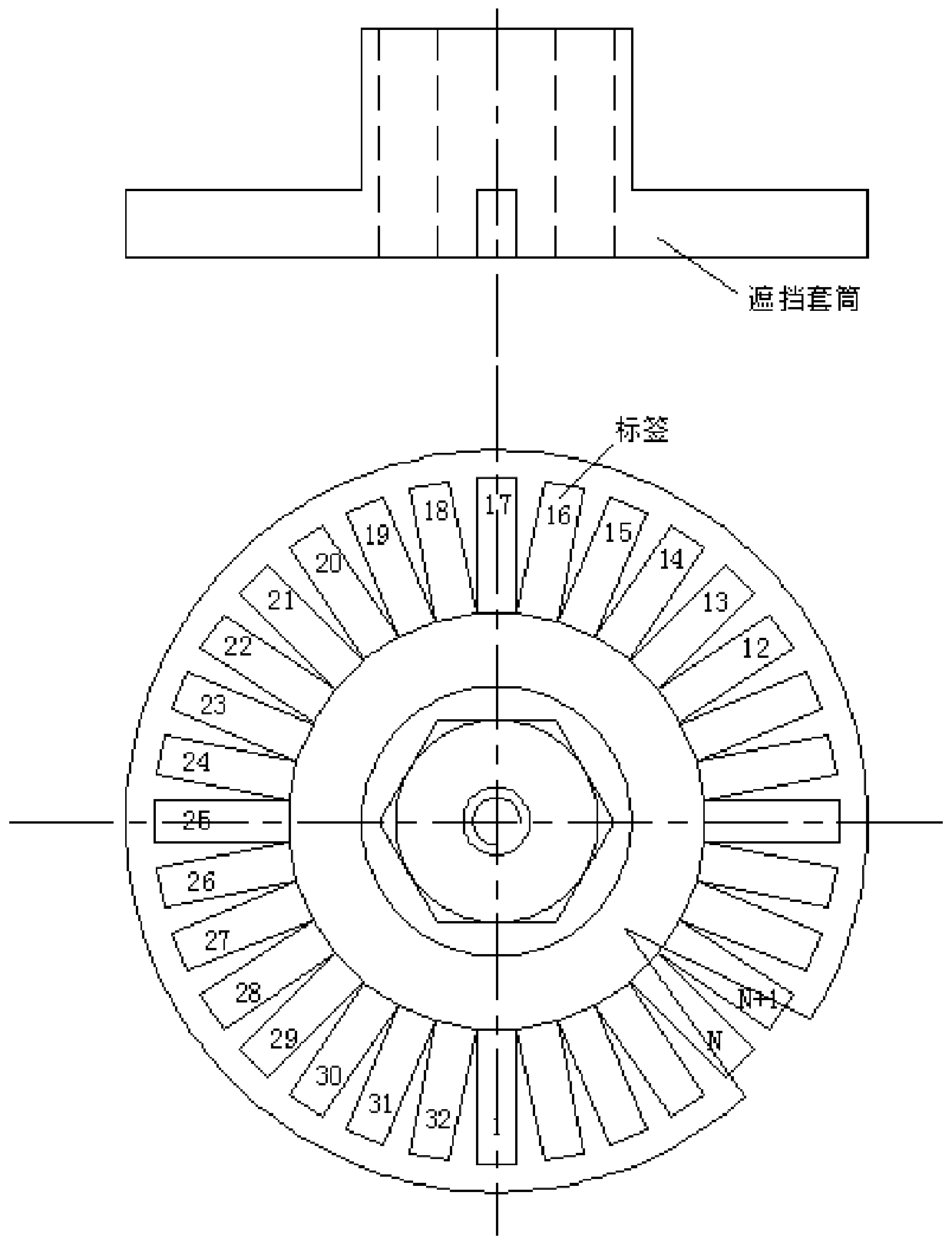

[0045] Such as figure 1 As shown, 32 anti-metal reflection RFID tags are evenly pasted around the bolts, the shielding sleeve is fixed on the nut, and the lower edge of the sleeve covers the tag. In each state, only one or two electronic tag information can be read by the reader Read.

[0046] The 32 tags are written with their respective number information in advance. An RFID card reader is fixed directly above the bolt, which can only read the information of the label not covered by the shielding sleeve, but cannot read the information of the label covered by the shielding sleeve.

[0047] The shielding sleeve is made of lightweight metal material, which can shield electromagnetic signals. The inner hole of the shielding sleeve has a regular hexagonal shape, and is connected with the hexagonal nut through the shape body. The scheme of this embodiment selects an ultra-high frequency RFID system with a frequency range of 300 MHz to 3 GHz, and a typical frequency value of 433 MHz....

Embodiment 2

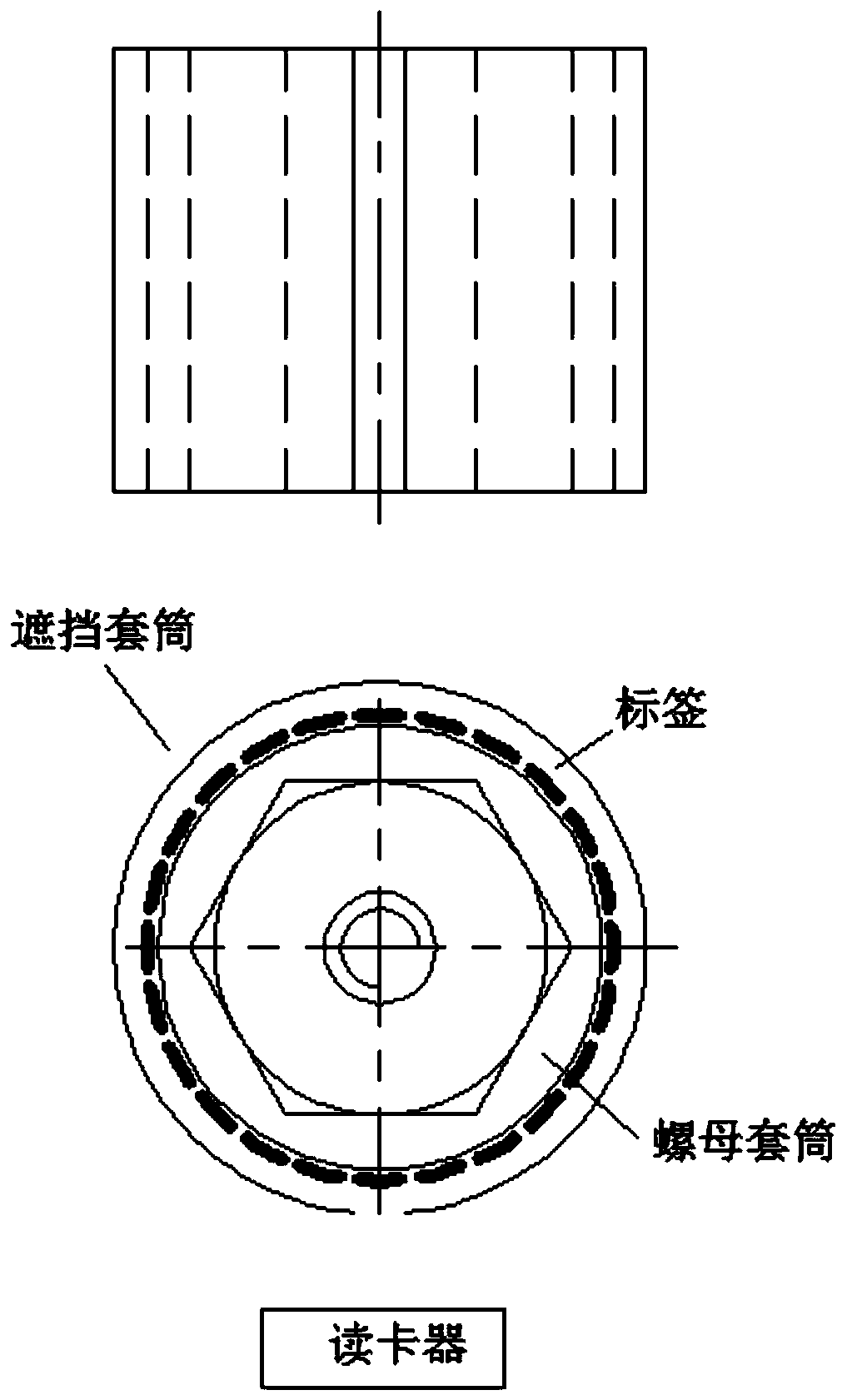

[0058] Such as figure 2 As shown, the monitoring system in the embodiment further includes a nut sleeve, 24 RFID tags are evenly pasted on the wall of the nut sleeve, and the nut sleeve and the hexagonal nut are connected by a shape fit. The shield sleeve is fixed on the periphery of the nut sleeve, and only one or two electronic tags can be read by the card reader in each state.

[0059] The working principle of the second embodiment is the same as that of the first embodiment, and there is only a difference in the system layout.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com