Anti-blocking flowmeter

A technology of flowmeter and component body, which is applied in the field of flowmeter, can solve the problems that the measurement system cannot be effectively and continuously measured, has no anti-blocking measures, and high maintenance costs, and achieves a wide range of measurement applications, good anti-blocking effects, and stable measurement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

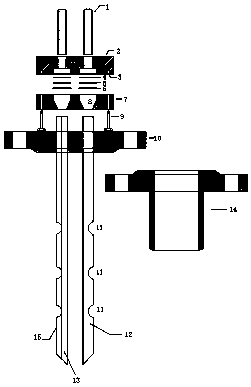

[0014] Such as figure 1 As shown, the flowmeter includes a short pressure pipe 1, an upper assembly body 2, a lower assembly body 7, a connecting piece 10, a negative end probe 12, a positive end probe 13 and a base 14, and the connecting piece 10 is installed above the base 14 to connect The lower assembly body 7 is installed above the part 10, and two expansion chambers 8 are arranged on the lower assembly body 7. The negative end probe 12 and the positive end probe 13 are installed on the connector 10, and the top ends of the negative end probe 12 and the positive end probe 13 are respectively Connected to the expansion chamber 8, the lower section of the negative end probe 12 and the positive end probe 13 is inserted into the base 14, a number of pressure-taking holes 11 are distributed on the lower section of the negative end probe 12 and the positive end probe 13, and the lower component body 7 is passed through the screw 9, the screw Install the upper assembly body 2 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com