Automatic screening part device

A technology for automatic screening and parts, applied in the direction of solid separation, classification, chemical instruments and methods, etc., can solve problems such as negligence, lack of accurate detection of parts, and easy leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

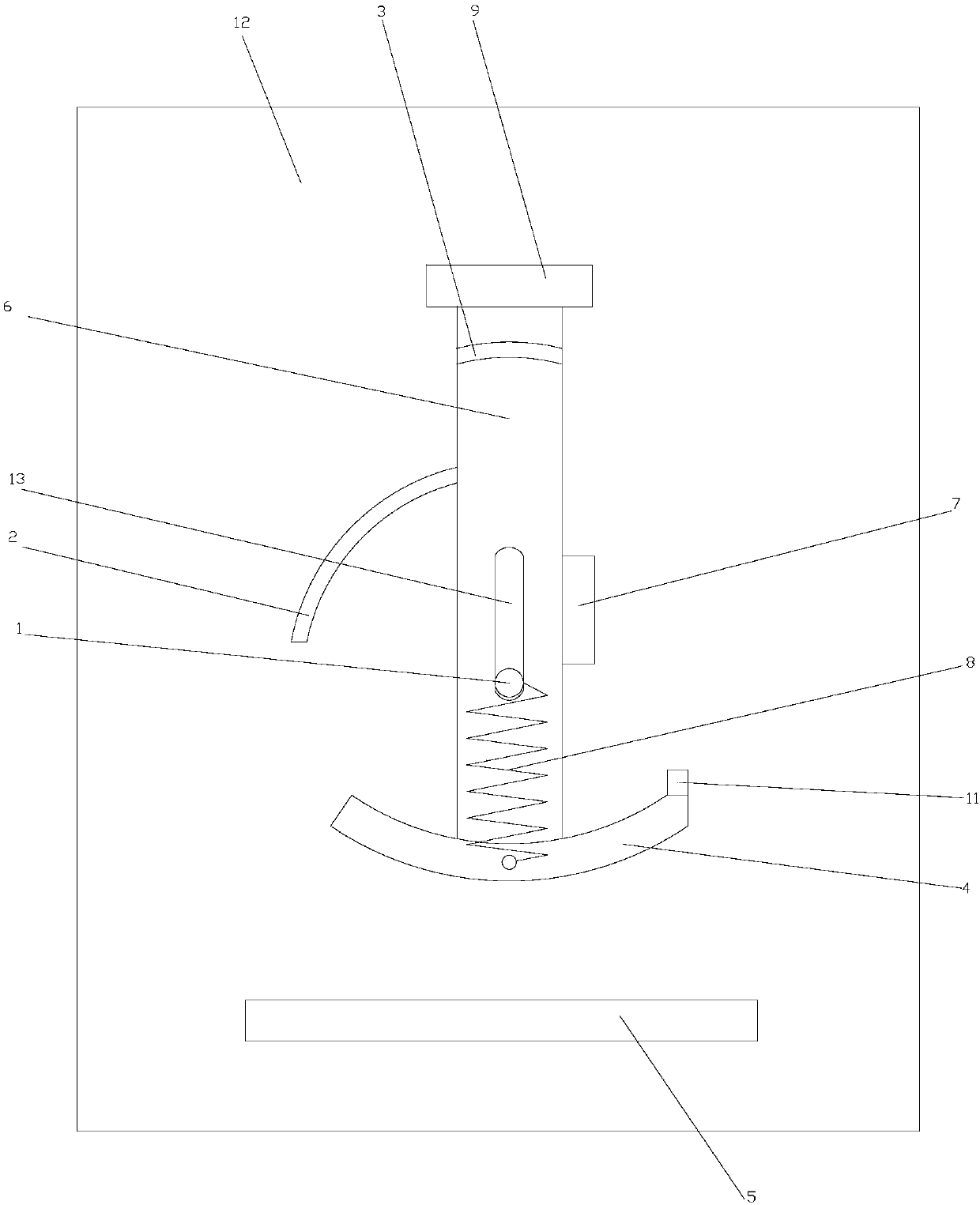

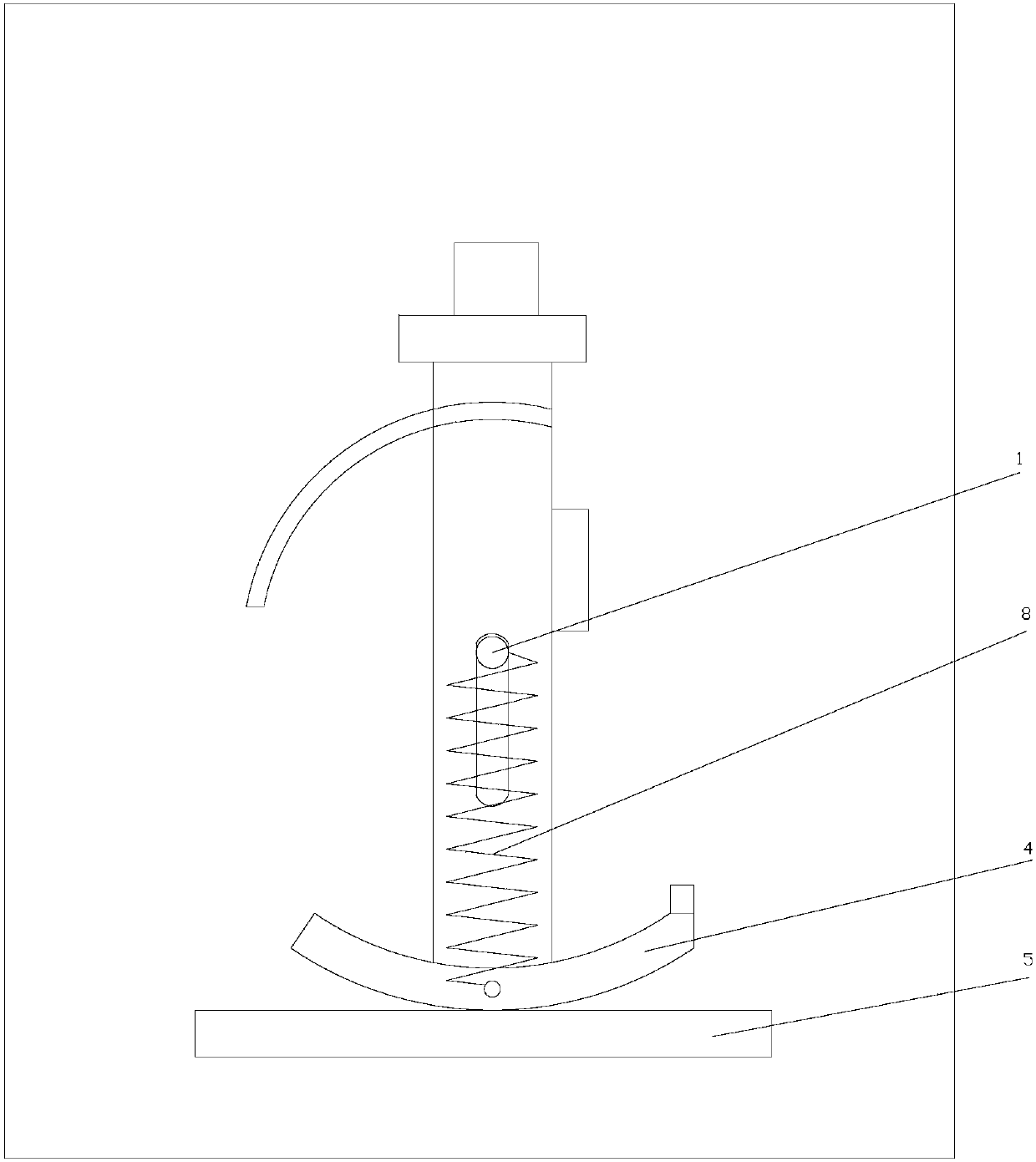

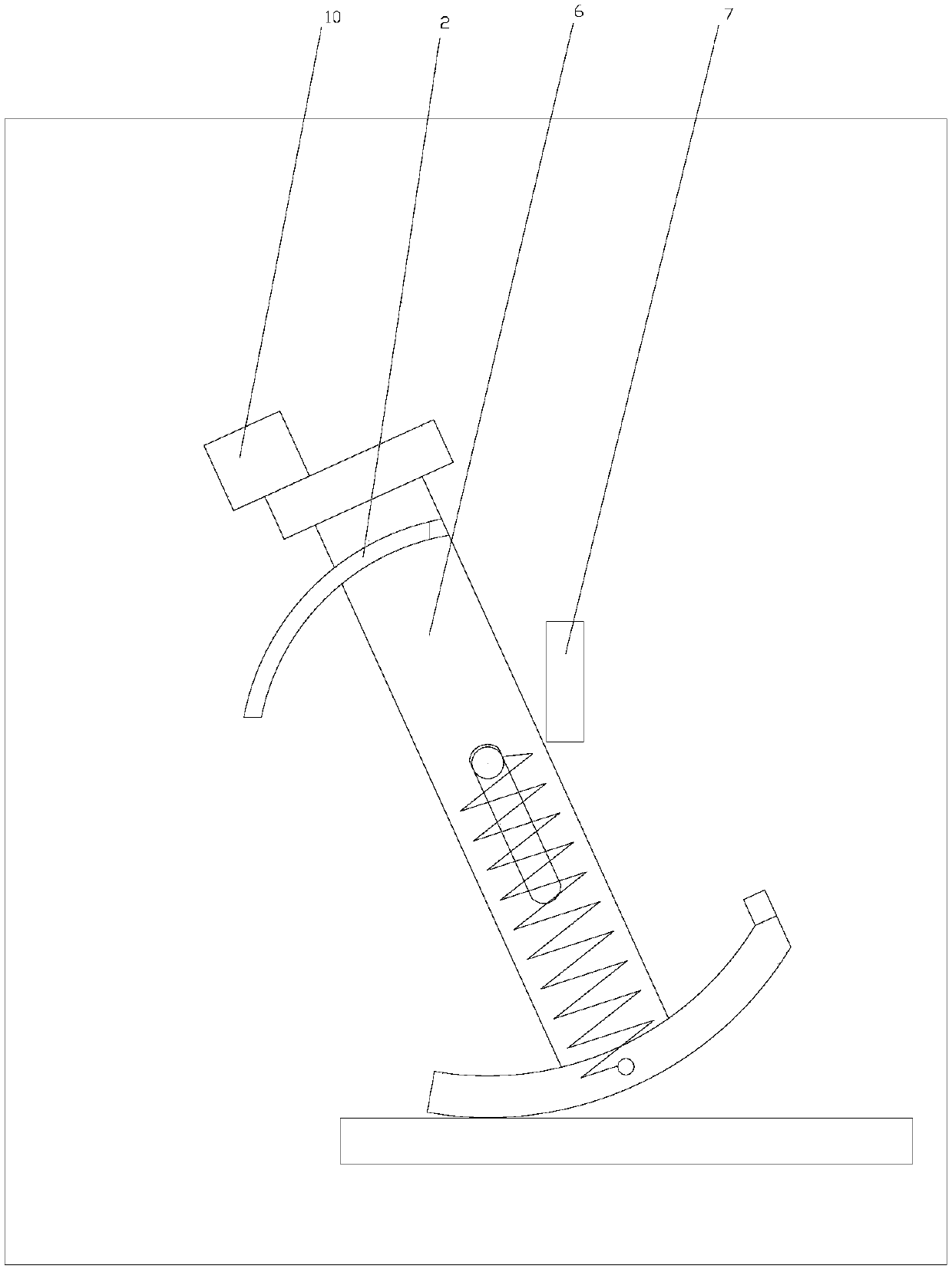

Embodiment 1

[0018] As shown in the figure, the automatic screening component device of the present invention includes a base 12, a swing plate 6 is rotatably connected to the base 12, a chute 13 is provided on the swing plate 6, a cylindrical pin 1 is arranged on the base 12, and a cylindrical pin 1 Located in the chute 13; the base 12 is respectively provided with a support block 7 and an arc rod 2 on both sides of the pendulum plate 6, the support block 7 is set on the base 12 higher than the cylindrical pin 1, and the arc rod 2 is connected with the cylindrical pin 1 It is arranged on the base 12 for the rotary shaft; the swing plate 6 is provided with an arc-shaped through hole 3 with the cylindrical pin 1 as the rotary shaft, the arc-shaped through-hole 3 and the arc-shaped rod 2 are located on the same vertical plane, and the arc-shaped rod 2 is located on the same vertical plane. 2 Inserted in the arc-shaped through hole 3 or separated from the arc-shaped through hole 3; the upper e...

Embodiment 2

[0023] As shown in the figure, the automatic screening component device of the present invention includes a base 12, a swing plate 6 is rotatably connected to the base 12, a chute 13 is provided on the swing plate 6, a cylindrical pin 1 is arranged on the base 12, and a cylindrical pin 1 Located in the chute 13; the base 12 is respectively provided with a support block 7 and an arc rod 2 on both sides of the pendulum plate 6, the support block 7 is set on the base 12 higher than the cylindrical pin 1, and the arc rod 2 is connected with the cylindrical pin 1 It is arranged on the base 12 for the rotary shaft; the swing plate 6 is provided with an arc-shaped through hole 3 with the cylindrical pin 1 as the rotary shaft, the arc-shaped through-hole 3 and the arc-shaped rod 2 are located on the same vertical plane, and the arc-shaped rod 2 is located on the same vertical plane. 2 Inserted in the arc-shaped through hole 3 or separated from the arc-shaped through hole 3; the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com