Inflation pump control method and device for air brake electric car

A control method and control device technology, applied in the direction of brake transmission, brakes, vehicle components, etc., can solve the problems of poor control accuracy of air pumps, achieve optimal exhaust time, ensure exhaust time, and promote downtime Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

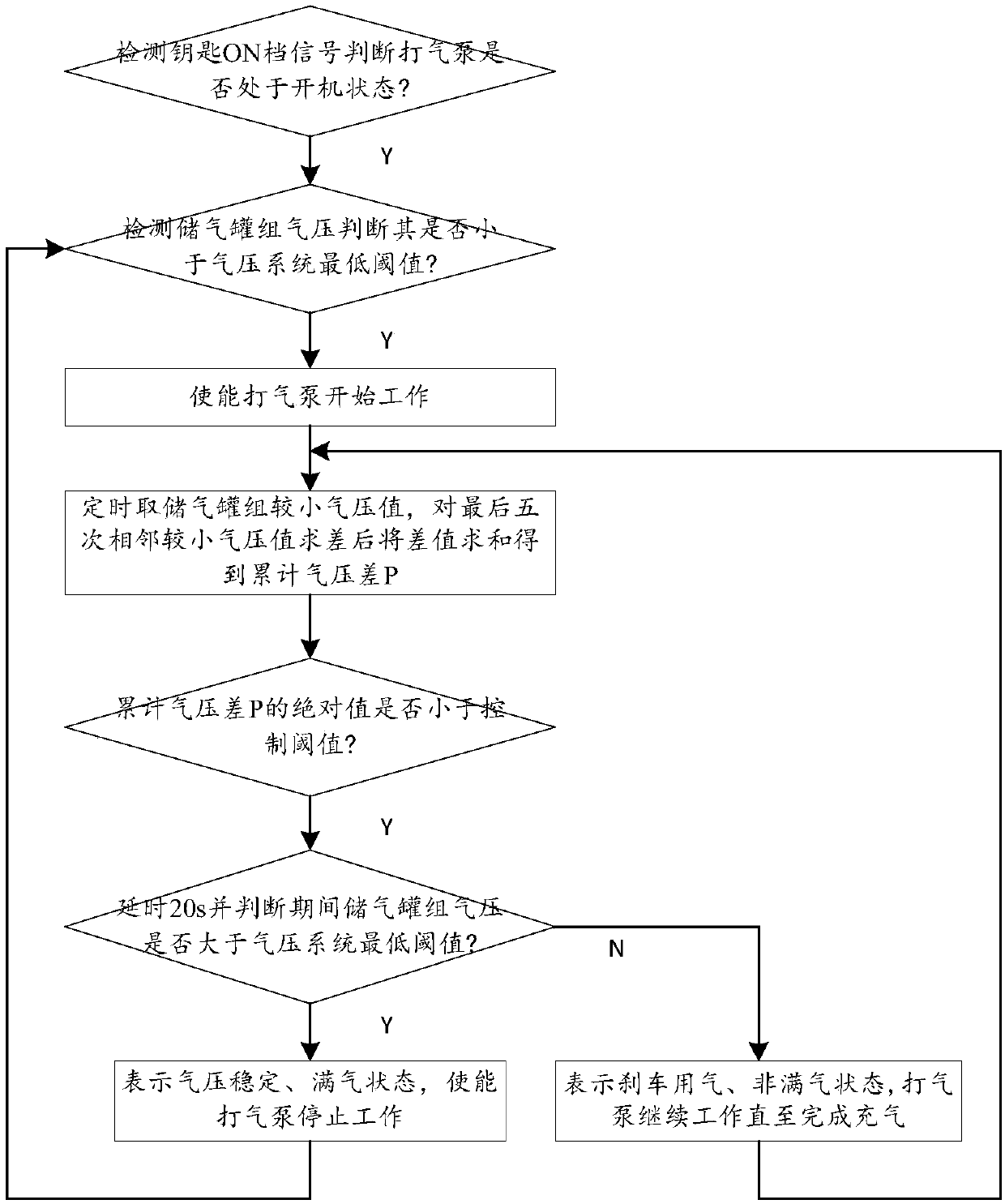

[0047] A method for controlling an air pump for an air brake electric vehicle, comprising the following steps:

[0048] Step 1: Detect the key ON gear signal to determine whether the air pump is on, if so, skip to step 2, otherwise end;

[0049] Step 2: Detect the air pressure of the air storage tank group to determine whether it is lower than the minimum threshold of the air pressure system. If so, enable the air pump to start working and skip to step 3. If not, continue to detect the air pressure of the air storage tank group;

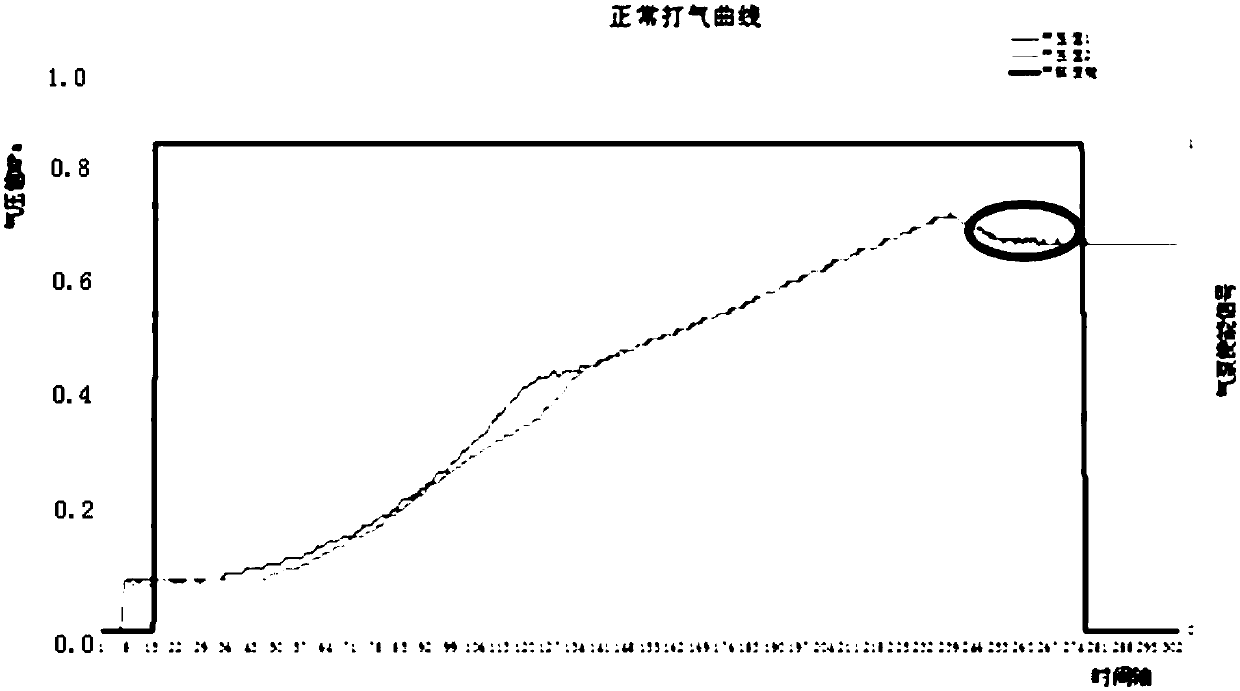

[0050] Step 3: Take the smaller air pressure value of the air storage tank group regularly, calculate the difference of the last five adjacent smaller air pressure values, and then sum the differences to obtain the cumulative air pressure difference P, and skip to step 4;

[0051] Step 4: Determine whether the absolute value of the accumulated air pressure difference P is less than the control threshold. If so, delay for 20s and judge whether the air...

Embodiment 2

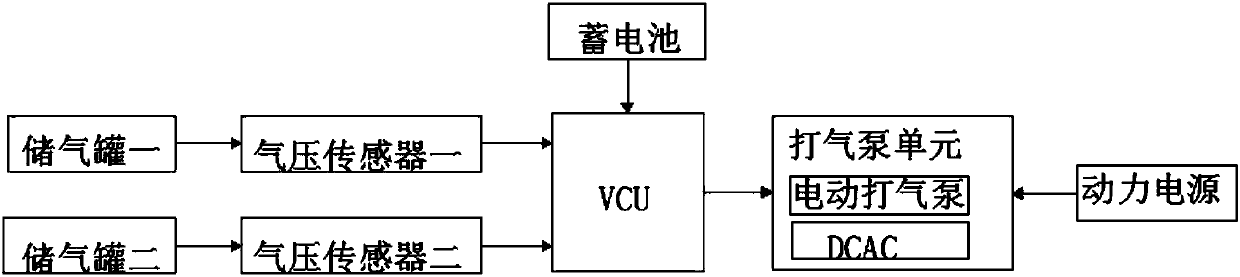

[0065] Working principle: an air pump control device for an air brake electric vehicle, including an air storage tank group, an air pressure sensor group, a VCU, an air pump unit and a power supply; the air pressure sensor group, VCU and the air pump unit are electrically connected in sequence, and the air pressure sensor is set In the gas storage tank; the power supply includes a storage battery and a power supply, the storage battery is electrically connected to the VCU, and the power supply is electrically connected to the air pump unit. The air storage tank group includes air storage tank 1 and air storage tank 2, and the air pressure sensor group includes air pressure sensor 1 and air pressure sensor 2; air pressure sensor 1 and air pressure sensor 2 are electrically connected to the VCU respectively, and the air pump unit includes an electric air pump and a DCAC , the electric air pump, DCAC and power supply are electrically connected in sequence, and the VCU is electrica...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap