Screw compressor economizer plenum for pulsation reduction

A technology for compressors and economizers, which is applied to independent rotary compressors, irreversible cycle compressors, compressors, etc., can solve problems such as pulsation propagation at the mouth of the economizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

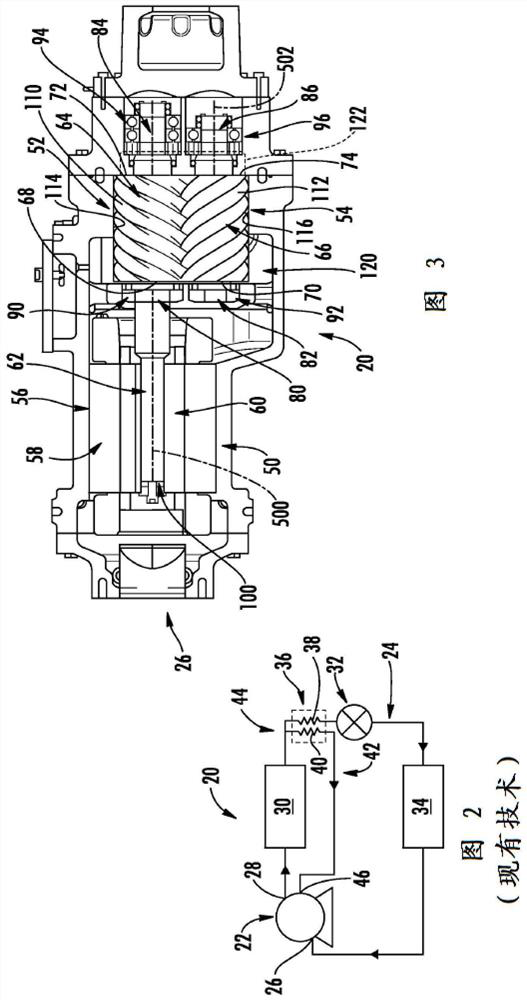

[0038]figure 2 A vapor compression system 20 with a compressor 22 along the recirculation refrigeration flow passage 24 is shown. For illustrative purposes, the exemplary system 20 is the most basic system. Many changes are known or may be yet to be developed. Along the flow path 20, the compressor 22 has a suction port (inlet) 26 and a discharge port (outlet) 28. In the normal operation mode, the refrigerant sucked in through the suction port 26 is compressed at a high pressure from the discharge port 28 and discharged to travel to the downstream side along the flow passage 24 and finally returns to the suction port. The sequence from upstream to downstream along the flow path 24 is: heat exchanger 30 (heat rejection heat exchanger in normal mode); expansion device 32 (for example, electronic expansion valve (EXV) or thermal expansion valve (TXV)); and Heat exchanger 34 (a heat-absorbing heat exchanger in the normal mode). Depending on the specific task involved, the exchanger can ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap