Electromagnetic shielding packaging method of point pre-fixed thin film circuit

A thin-film circuit and electromagnetic shielding technology, which is applied in the direction of circuit devices, circuits, printed circuits, etc., can solve problems such as difficult to avoid circuit electromagnetic interference, inconvenient metal cavity processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

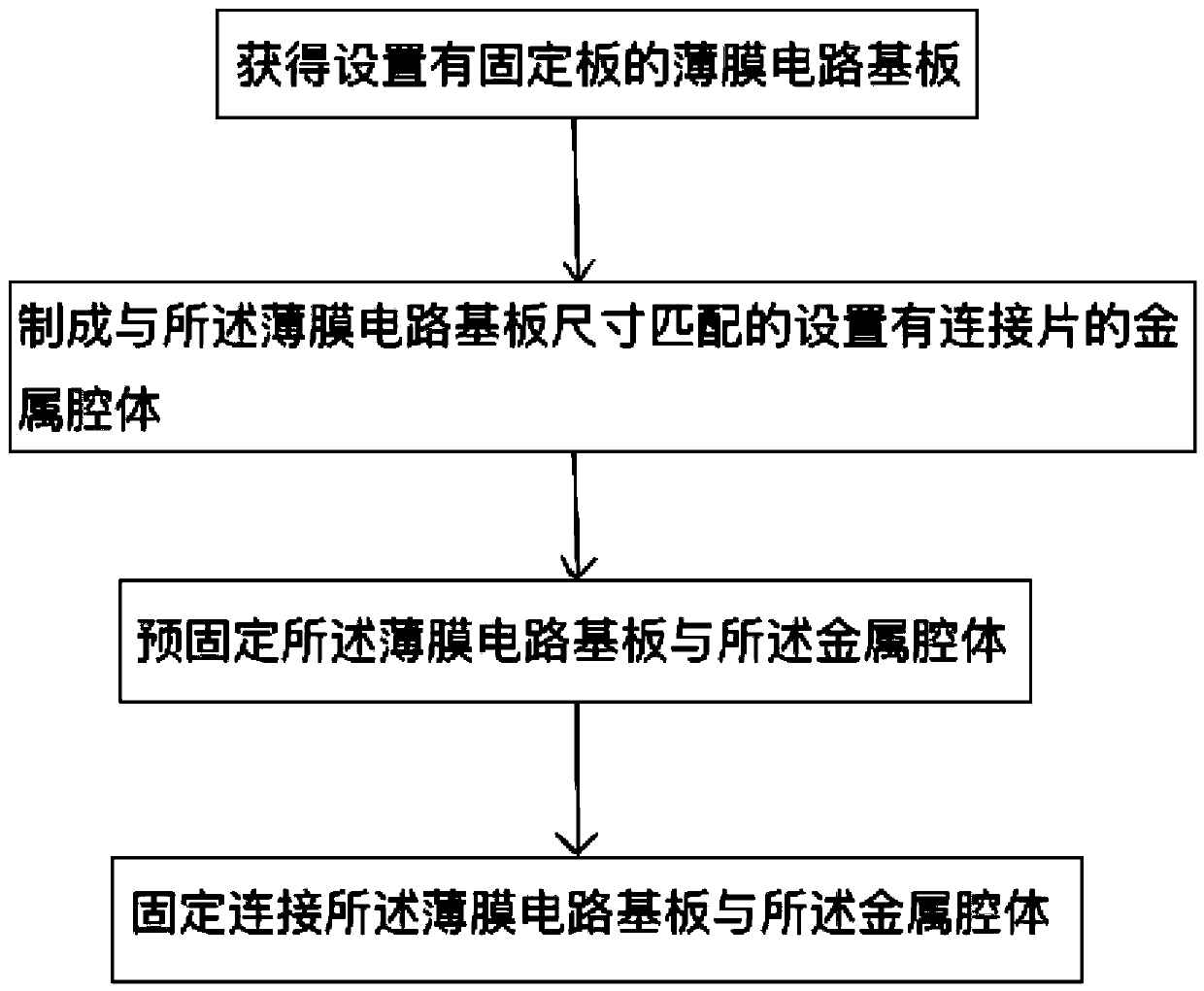

[0020] An electromagnetic shielding packaging method for point pre-fixed film circuits, comprising:

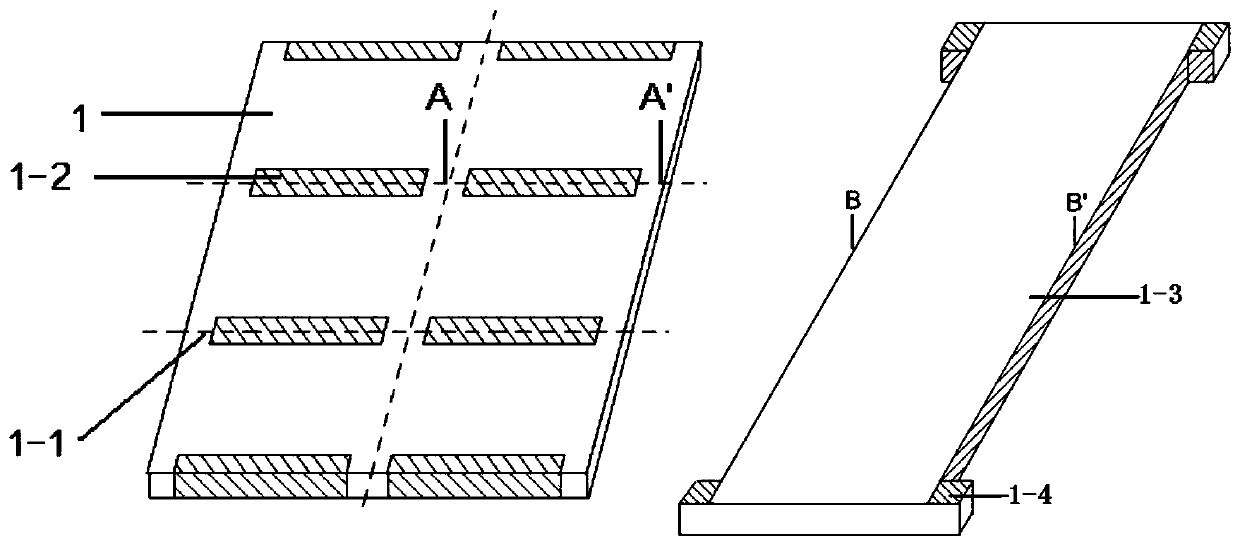

[0021] Step (a) obtaining a thin film circuit substrate provided with a fixing plate;

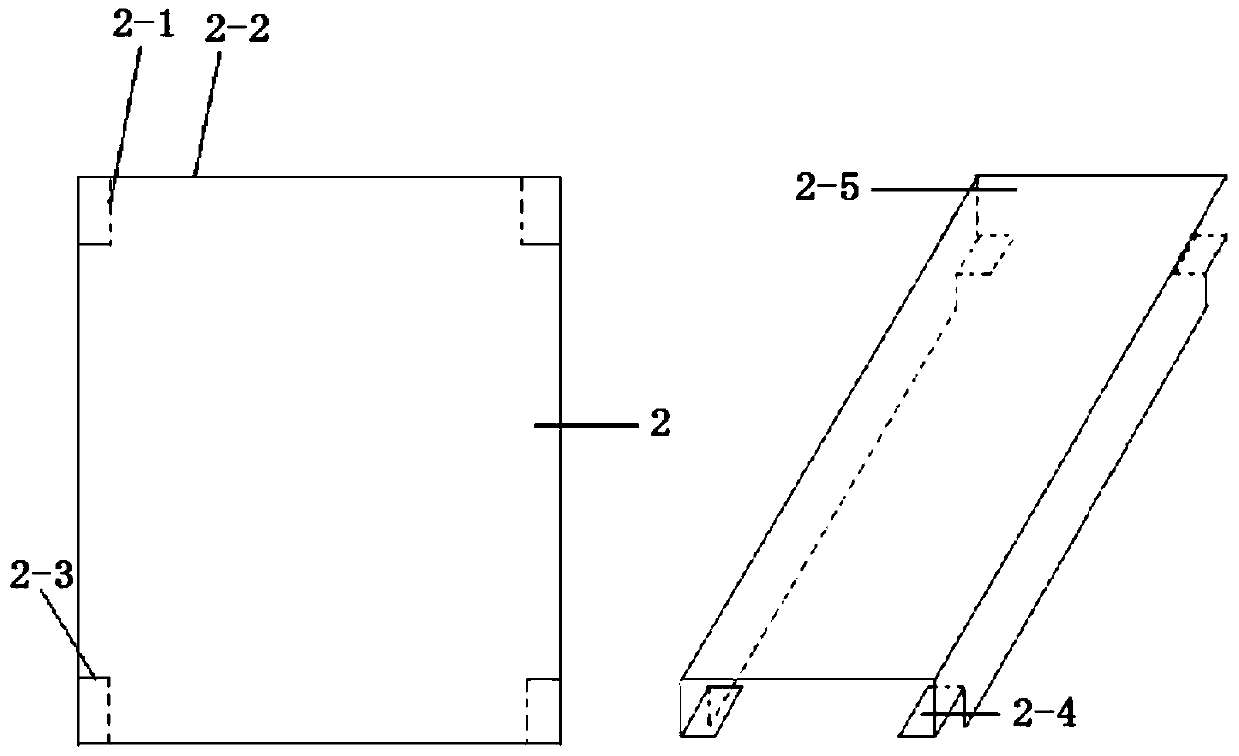

[0022] Step (b) making a metal cavity provided with connecting pieces matching the size of the thin film circuit substrate;

[0023] Step (c) pre-fixing the thin film circuit substrate and the metal cavity.

[0024] Further, the front side surface of the thin film circuit substrate is covered with a metal film. The front and side of the thin film circuit substrate are covered with a metal film, which can effectively guarantee the metal interconnection effect on the side of the circuit.

[0025] Further, the method for obtaining a thin film circuit substrate provided with a fixing plate includes:

[0026] Step (a-1) opening an array through cavity shorter than the length of the circuit along the circuit array in the circuit substrate;

[0027] Step (a-2) plating a metal film on the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com