A kind of food waste treatment device

A technology of food waste and processing equipment, which is applied in water supply equipment, indoor sanitary pipeline installations, buildings, etc. It can solve the problems of no flushing of the crushing chamber, clogging of food waste, and food waste not reaching the discharge size, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

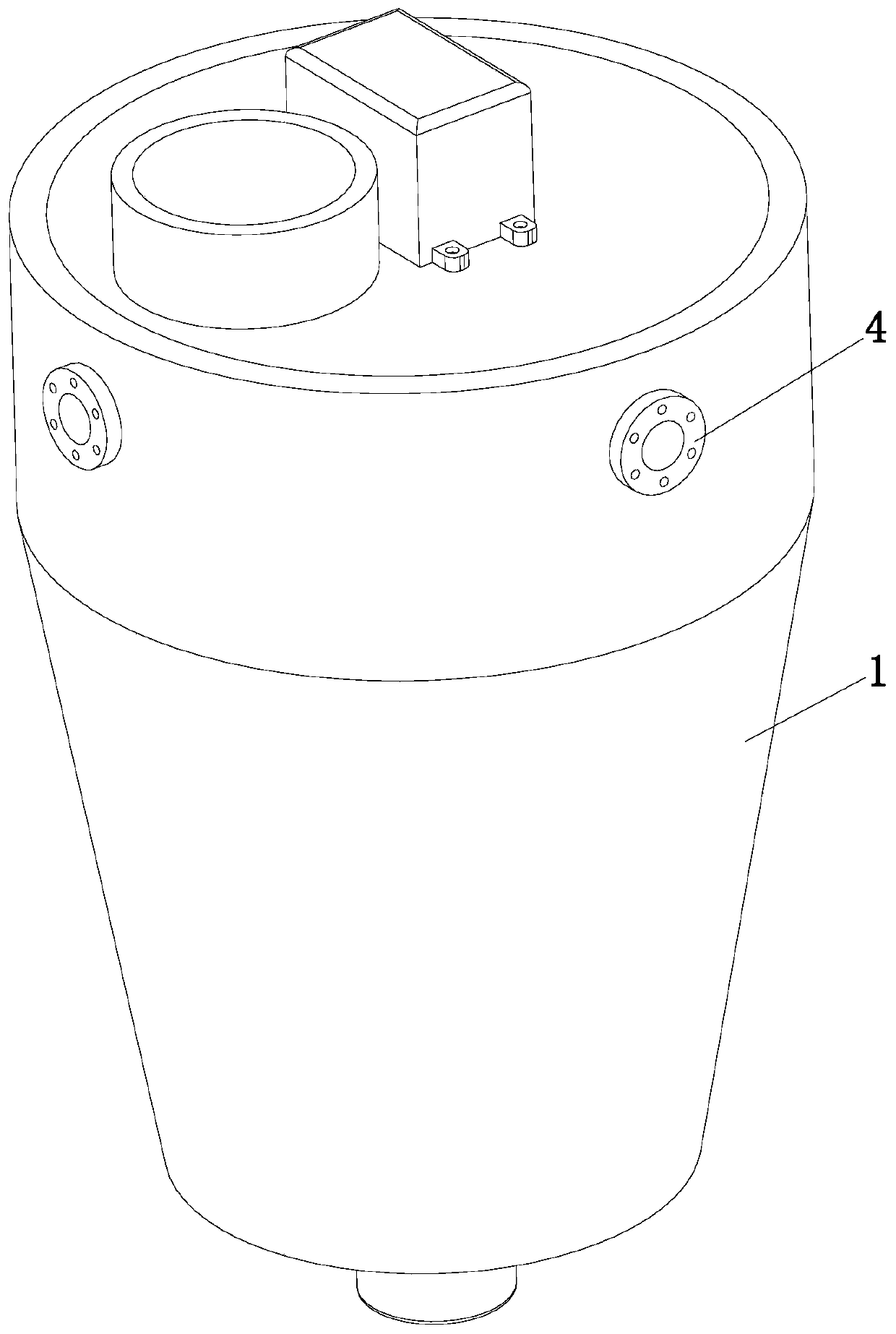

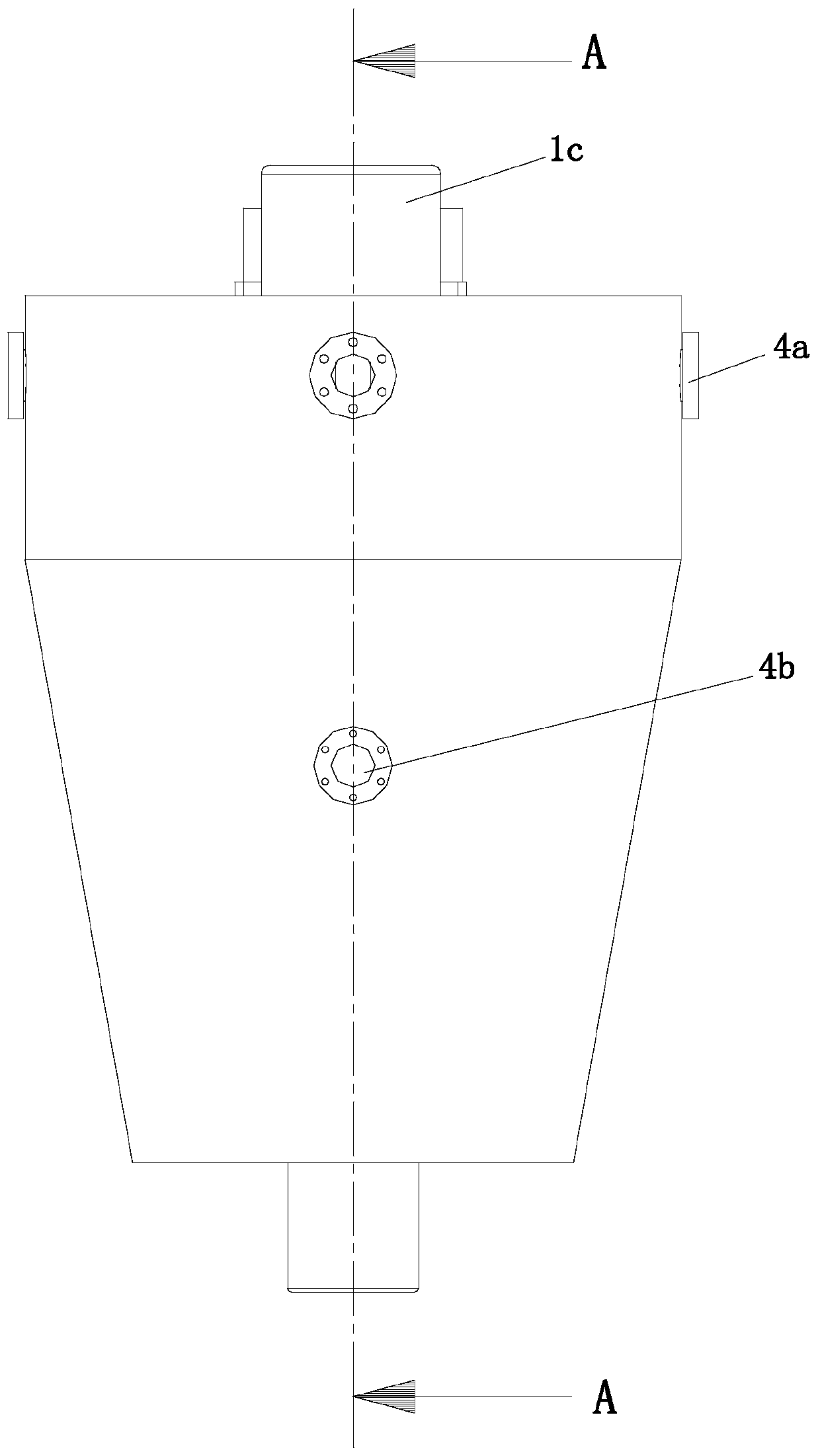

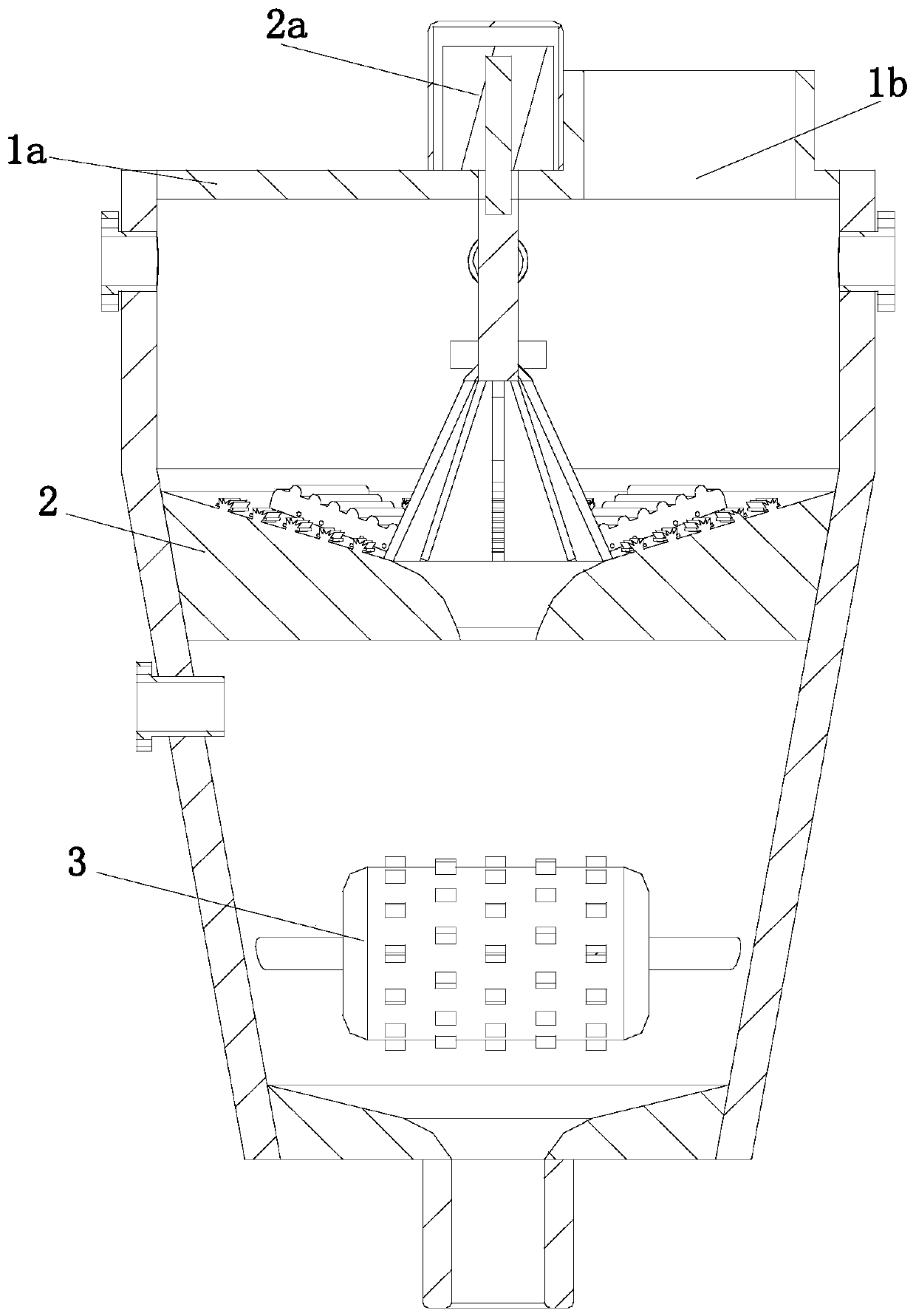

[0034] refer to Figure 1 to Figure 12 A food waste treatment device shown includes a treatment box 1, a primary crushing mechanism 2, a secondary crushing mechanism 3, and an inflow flushing mechanism 4. The treatment box 1 is an inverted conical structure and is a hollow structure. The processing box 1 includes an openable upper cover plate 1a, and the upper cover plate 1a is provided with a feed port 1b for the food waste to be processed to enter the processing box 1, and the primary crushing mechanism 2 and the secondary crushing mechanism 3 It is sequentially arranged in the treatment box 1 along the flow direction of the food waste, the water inlet flushing mechanism 4 is arranged on the outer peripheral wall of the treatment box 1 and communicates with the inside of the treatment box 1, and the primary crushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com