A kind of semi-aromatic polyamide resin and molding composition thereof

A technology of polyamide resin and molding composition, which is applied in the field of polymer materials and can solve the problem of consuming large energy by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

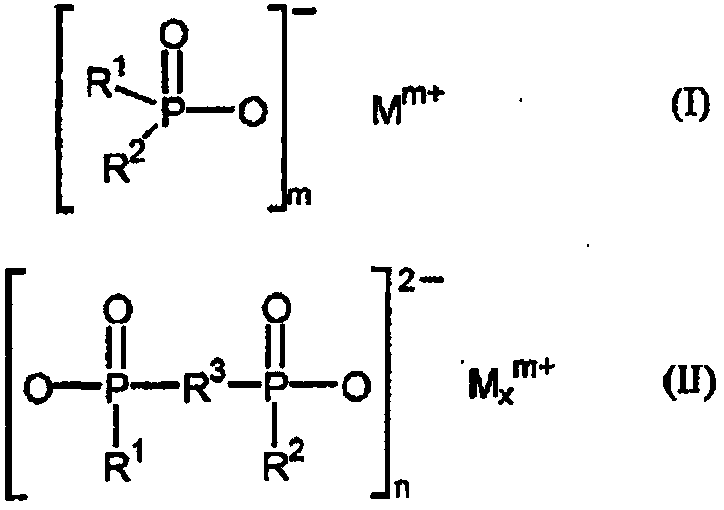

Method used

Image

Examples

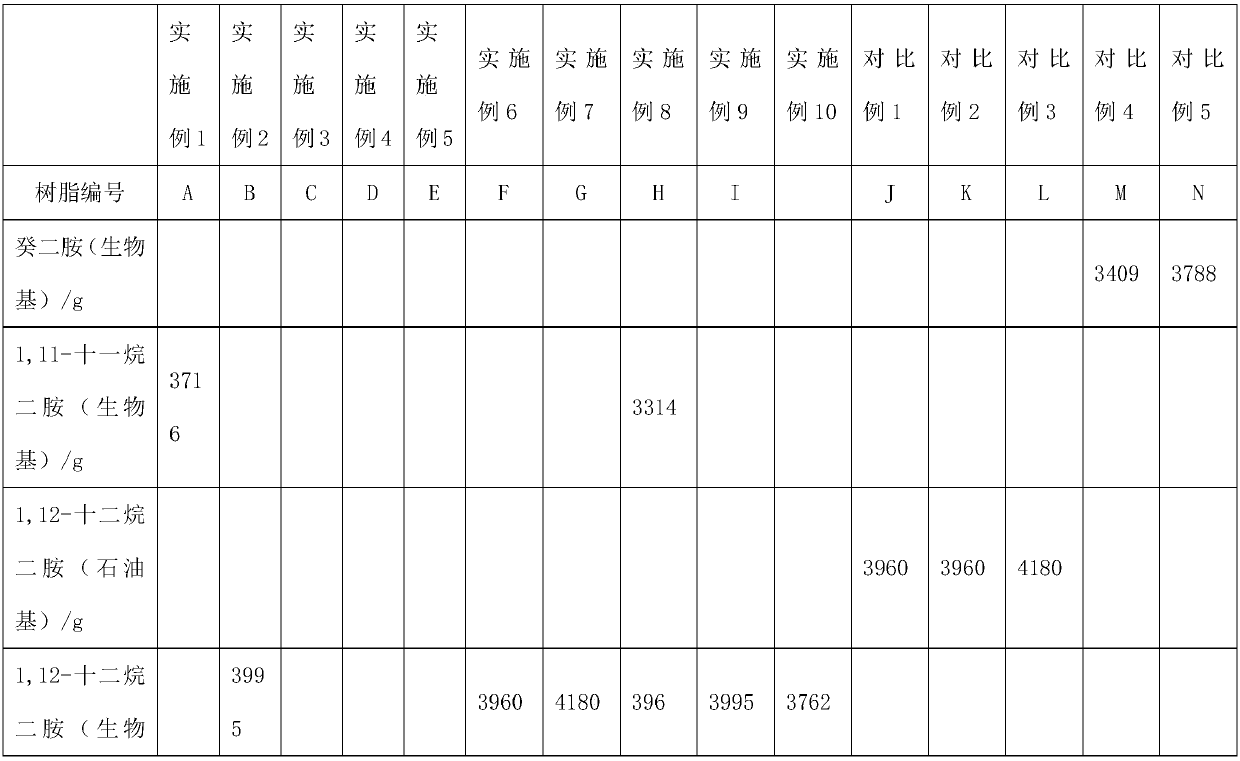

Embodiment 1~10 and comparative example 1~5

[0112] In the autoclave equipped with magnetic coupling stirring, condenser, gas phase port, feeding port, pressure explosion-proof port, add the reaction raw materials according to the ratio of Table 1, then add benzoic acid, sodium hypophosphite and deionized water, the amount of benzoic acid It is 2.5% of the total amount of diamine, diacid, lactam and amino acid, the weight of sodium hypophosphite is 0.1% of the weight of other feeding materials except deionized water, and the weight of deionized water is 30% of the total weight of feeding; Inject high-purity argon as a protective gas to start the reaction. The temperature of the reaction mixture was raised to 220°C-230°C and stirred for 3-5 hours, then the valve was opened to slowly release the pressure and drain water while keeping the temperature and pressure constant. Drain until the drainage volume reaches 70% of the input deionized water volume. At this time, the temperature began to rise, and the temperature was ra...

Embodiment 11~16 and comparative example 6-9

[0119] Examples 11-16 and Comparative Examples 6-9: Preparation of semi-aromatic polyamide molding compositions

[0120] Mix the semi-aromatic polyamide resin and additives uniformly in the high-mixer according to the formula in Table 2, and then add them into the twin-screw extruder through the main feeding port, and feed the reinforcing filler through the side feeding scale, extrude, and pass The semi-aromatic polyamide molding composition is obtained after water cooling, granulation and drying.

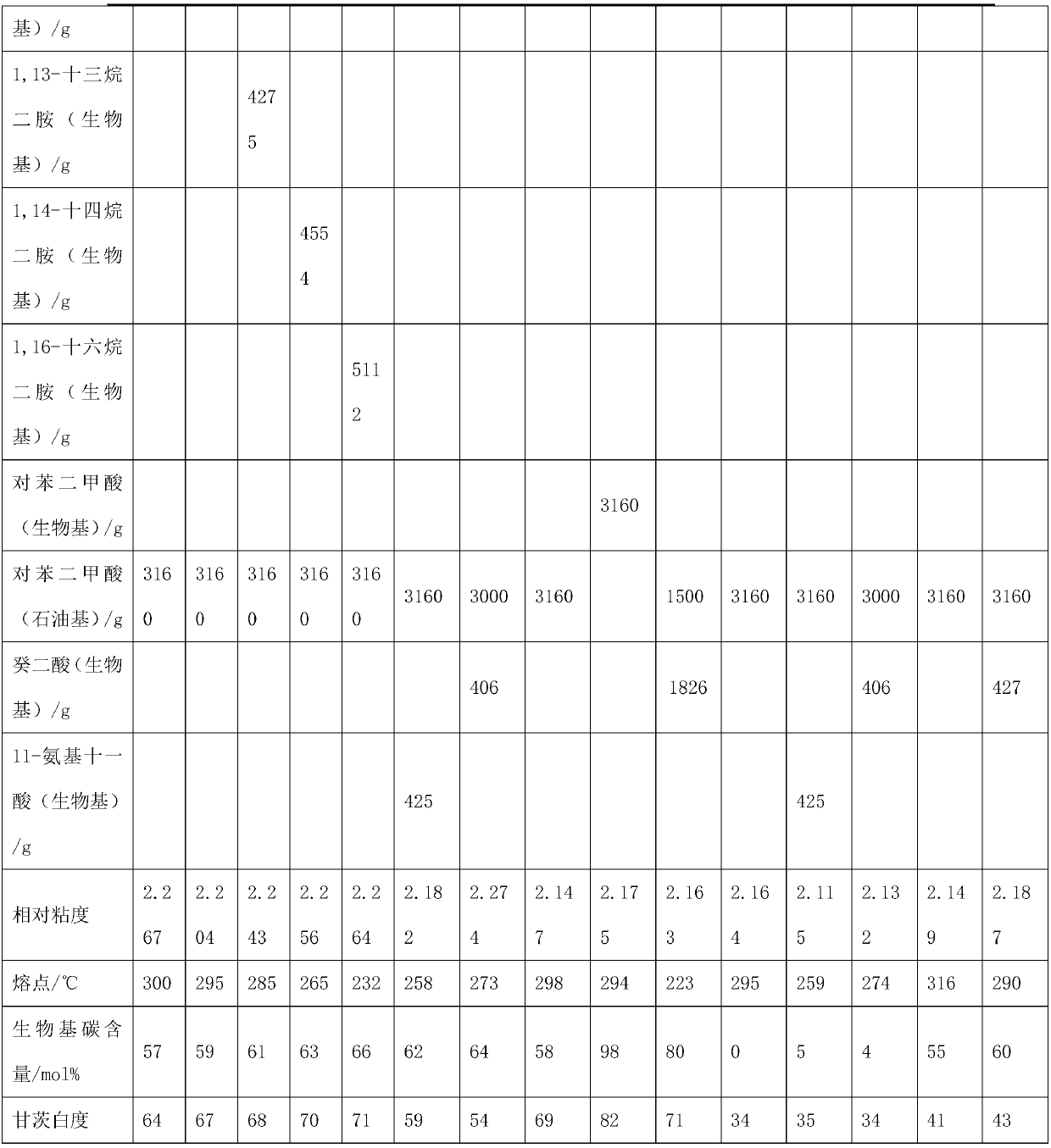

[0121] Table 2 The formulation and performance test results of the semi-aromatic polyamide molding composition (the formulations in the following table are all parts by weight)

[0122]

[0123] It can be seen from the results in Table 2 that under the same formulation of the molding composition, the Ganz whiteness of the molding composition containing the semi-aromatic polyamide resin of the present invention also has obvious advantages.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com