Method and device for assembling adjustable camshaft

A technology of camshafts and shaft segments, which is applied in the field of assembling adjustable camshafts, and can solve problems such as the inability to guarantee friction-free rotation or adjustment, and the occurrence of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

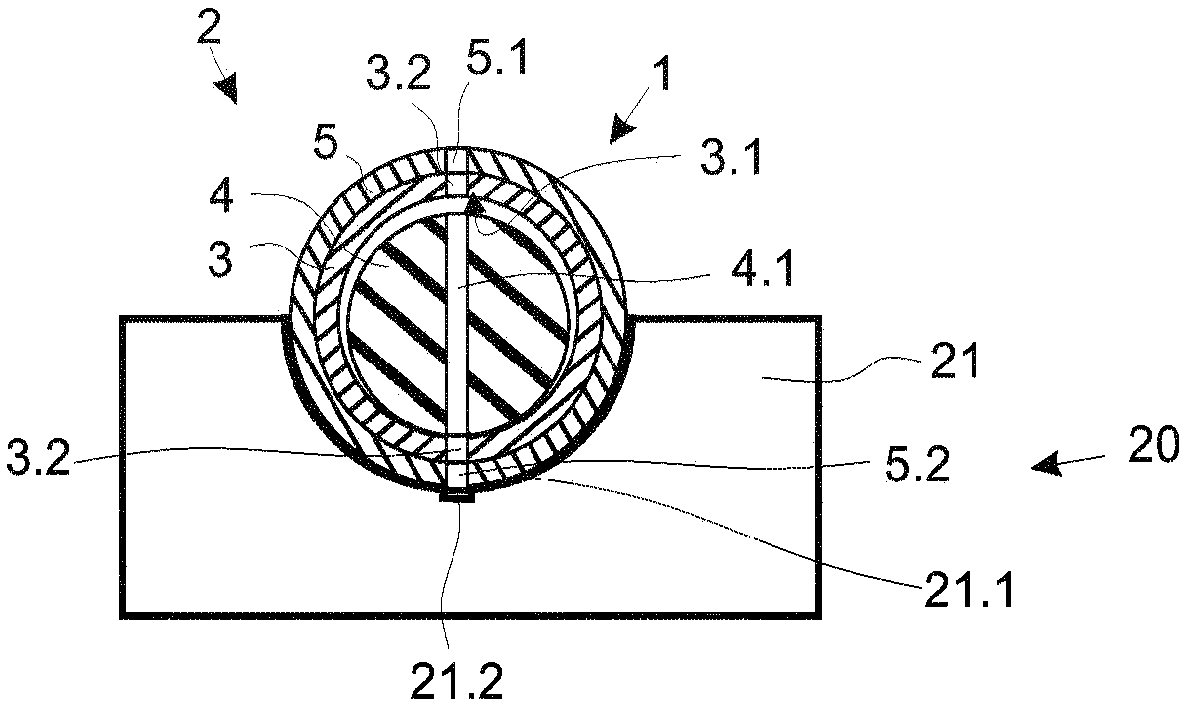

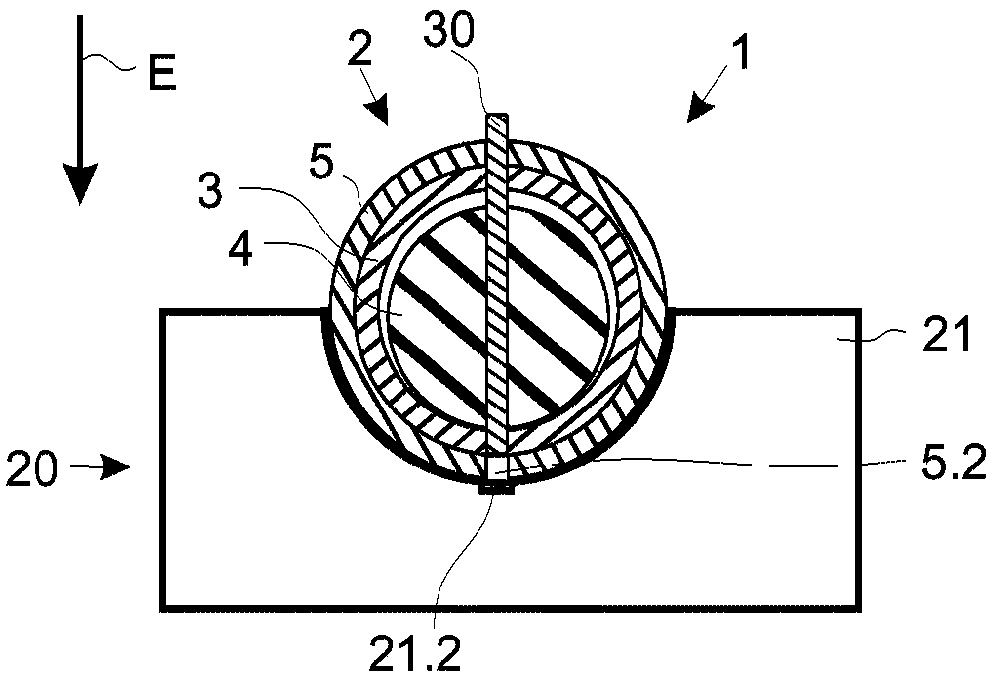

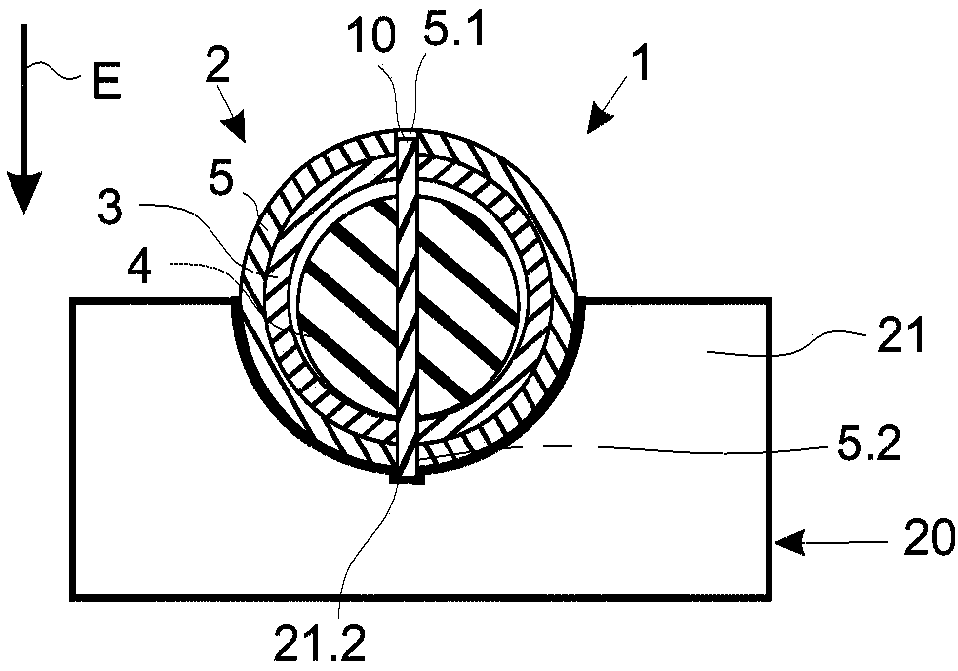

[0036] figure 1 is a cross-sectional view of an embodiment of an adjustable camshaft 1 with an outer shaft 3 and an inner shaft 4 extending through a through hole 3.1 of the outer shaft 3 . The inner shaft 4 is arranged eccentrically with respect to the outer shaft 3 , in particular in the through-opening 3 . 1 of the outer shaft 3 . The inner shaft 4 comprises an inner shaft bore 4.1. The outer shaft 3 comprises a first outer shaft hole 3.2 and a second outer shaft hole 3.3. figure 1 The illustrated embodiment of the adjustable camshaft 1 also includes a fixing element 5 . The fastening element 5 is advantageously designed in the form of a ring, in particular a sleeve. The outer shaft 3 and the inner shaft 4 extend through the fixing element 5 , in particular through a through-opening of the fixing element 5 . Advantageously, the fixing element 5, the outer shaft 3 and the inner shaft 4 have a common longitudinal central axis after final assembly, as described below Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com