Deburring machine

A deburring machine and deburring technology, applied in the field of parts processing, can solve the problems of increasing production costs, affecting product quality, and large amount of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

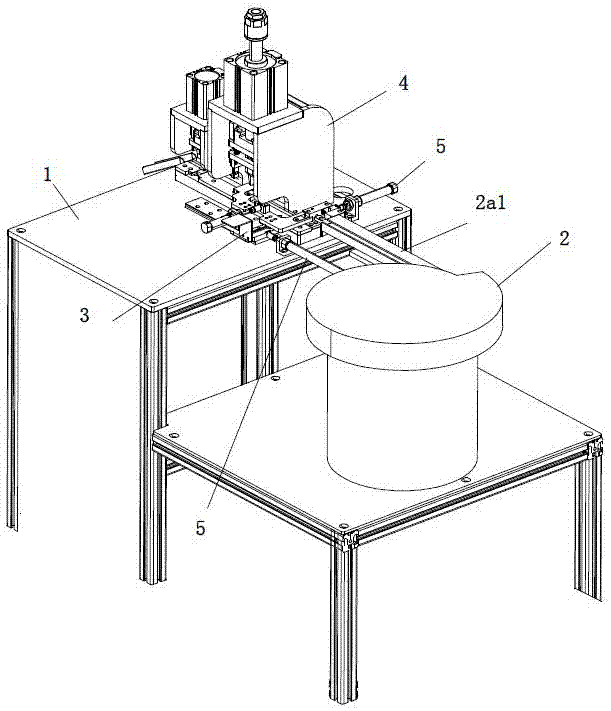

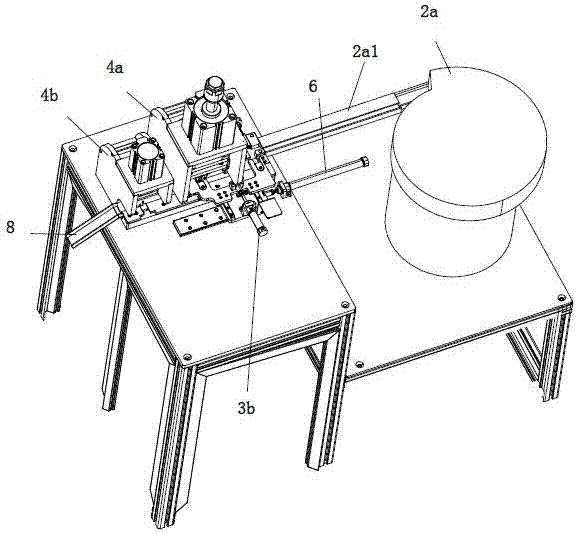

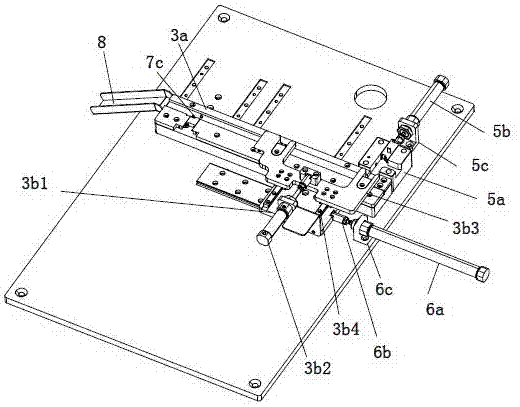

[0026] refer to Figure 1 to Figure 9 The shown deburring machine includes a working platform 1, a feeding device 2, a material moving device 3 and a deburring device 4, and the feeding device 2, the material moving device 3 and the deburring device 4 are all located on the working platform 1 The top is fixedly connected with the working platform 1, and the feeding device 2 includes a vibrating feeding tray 2a and a feeding track 2a1, one end of the feeding track 2a1 is fixedly connected with the vibrating feeding tray 2a, and the other end of the feeding track 2a1 extends to the material shifting device 3 and matched with it, the side of the feeding track 2a1 is provided with a pusher 5 that pushes the workpiece at the discharge end of the feeding track 2a1 to the material-moving device 3, and the material-moving d...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap