Plastic composite membrane bag for packaging

A composite film and packaging technology, applied in the field of packaging, can solve the problems of excessive accumulation of waste, not easy for operators to find, and difficult to clean up, and achieves good use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

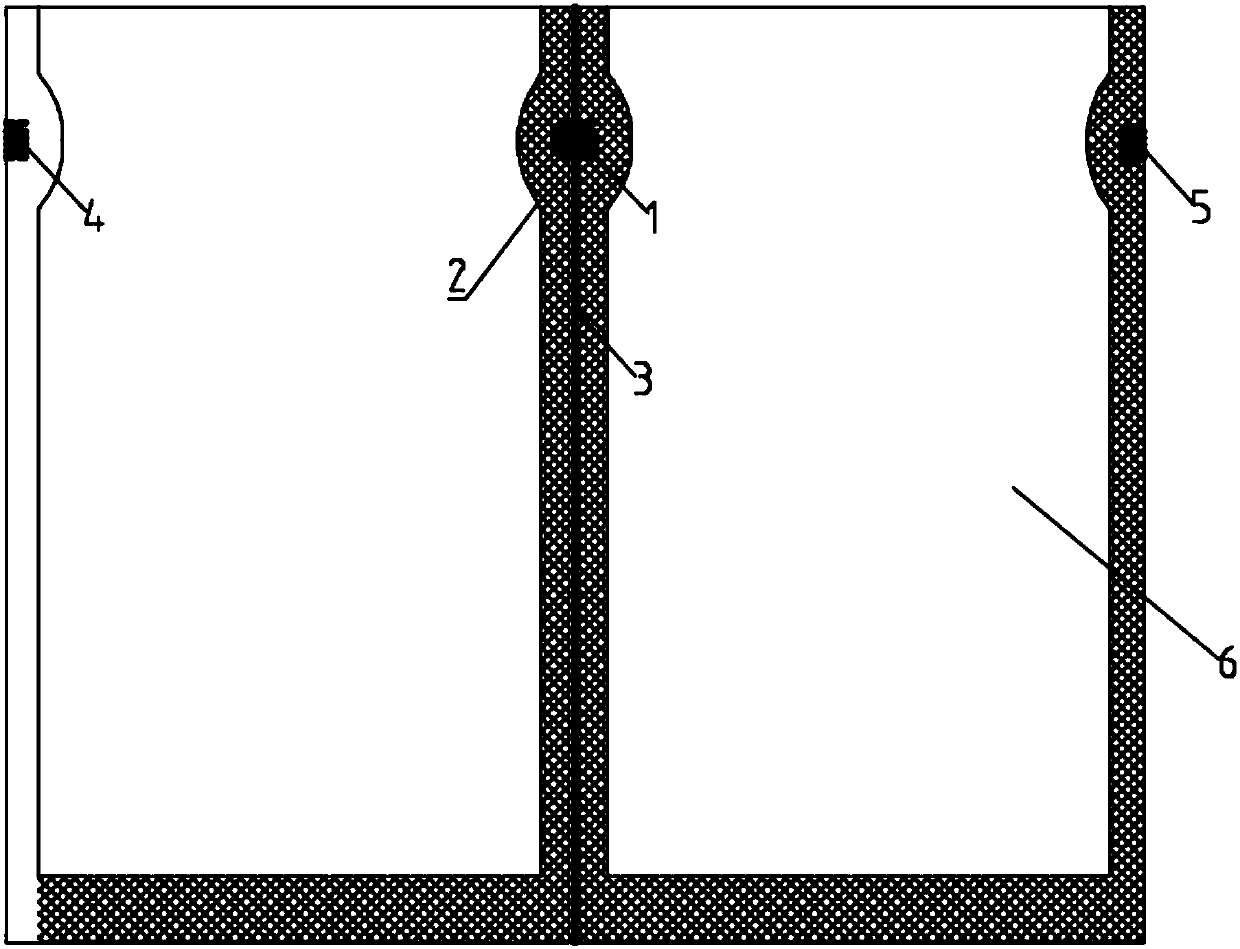

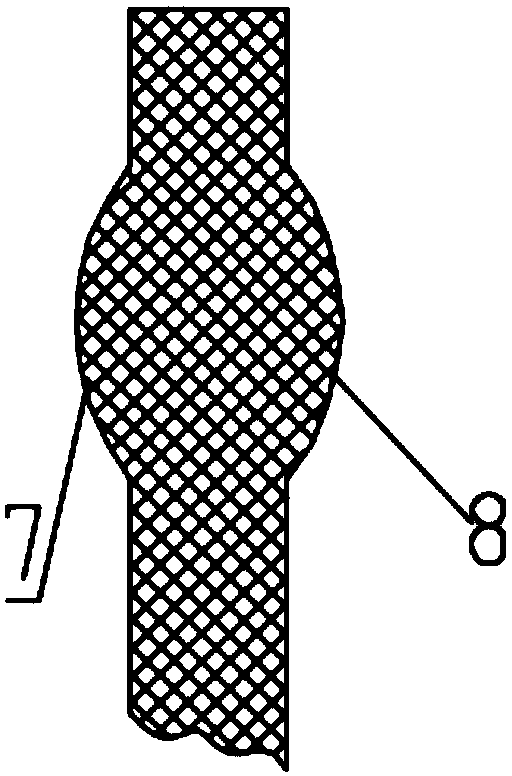

[0016] see Figure 1-2 , a plastic composite film bag for packaging, comprising a main body 6, a middle slitting line 3 is arranged in the middle of the main body 6, and an easy-tear opening 1 made by a shearing process with 11 rows by 6 columns is arranged on the middle slitting line 3, The starting distance between the easy-tear openings 1 in each row is 1mm different, the distance between the easy-tear openings 1 in each column is 1mm and the number of easy-tear openings 1 in adjacent columns is different, and the leftmost side of the body 6 is provided with a left-hand easy-tear opening. Tear 4, the rightmost side of the body 6 is provided with the right easy-tear 5, the easy-tear 1, the left easy-tear 4 and the right easy-tear 5 are all provided with arc-shaped compensation edges 2, Easy tear 1 is located in the center of compensation edge 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc length | aaaaa | aaaaa |

| Chord length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap