Blanking, stretching and punching die

A blanking die and punch punch technology, which is applied to forming tools, manufacturing tools, feeding devices, etc., can solve the problem of affecting the service life of the fan coil in the hemming process, punching cracks, uneven force on the punching edge, etc. problem, to achieve the effect of short punching action time, reducing the generation of punching cracks, and less cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described in detail below with reference to the examples and figures, but the embodiments of the present invention are not limited thereto.

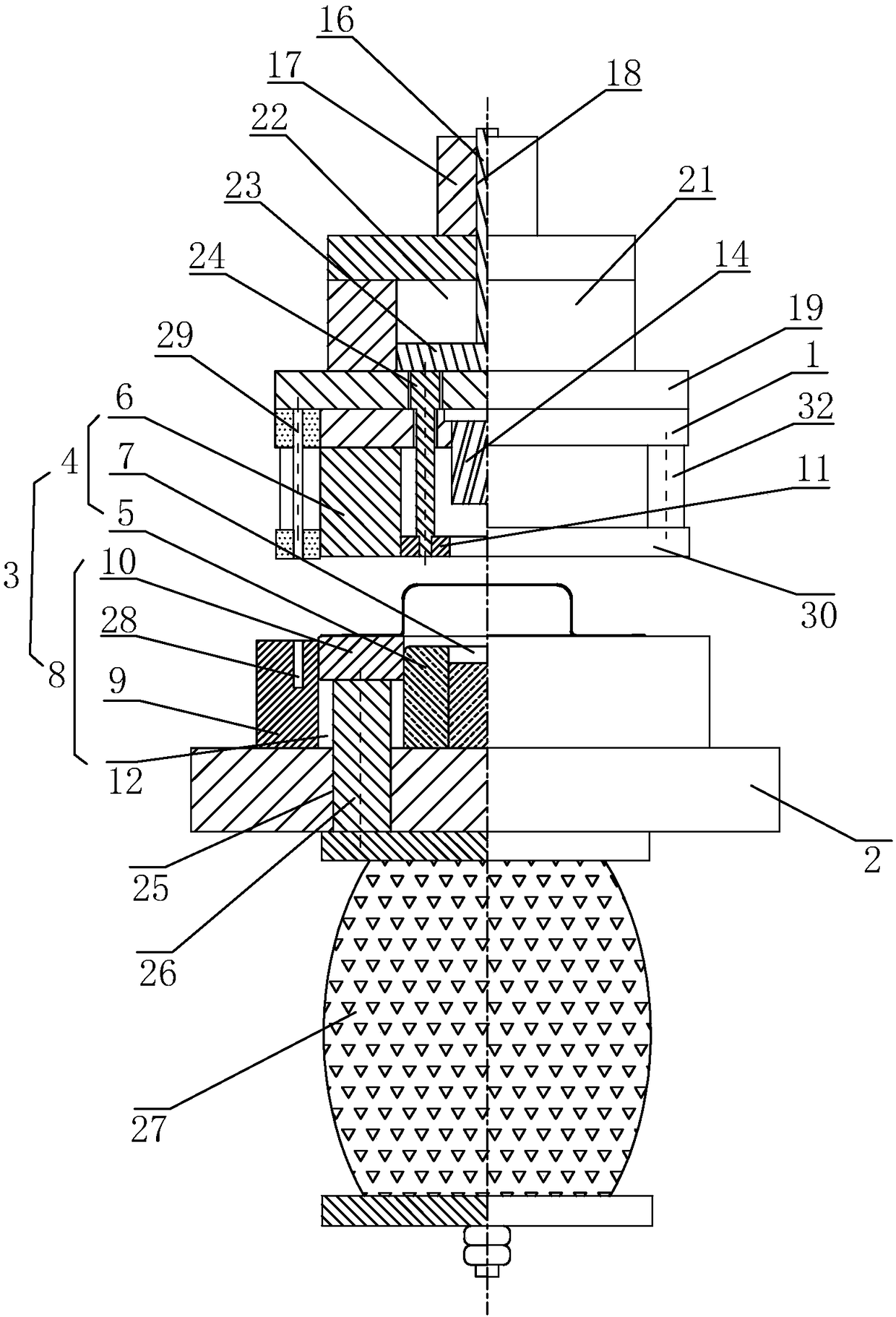

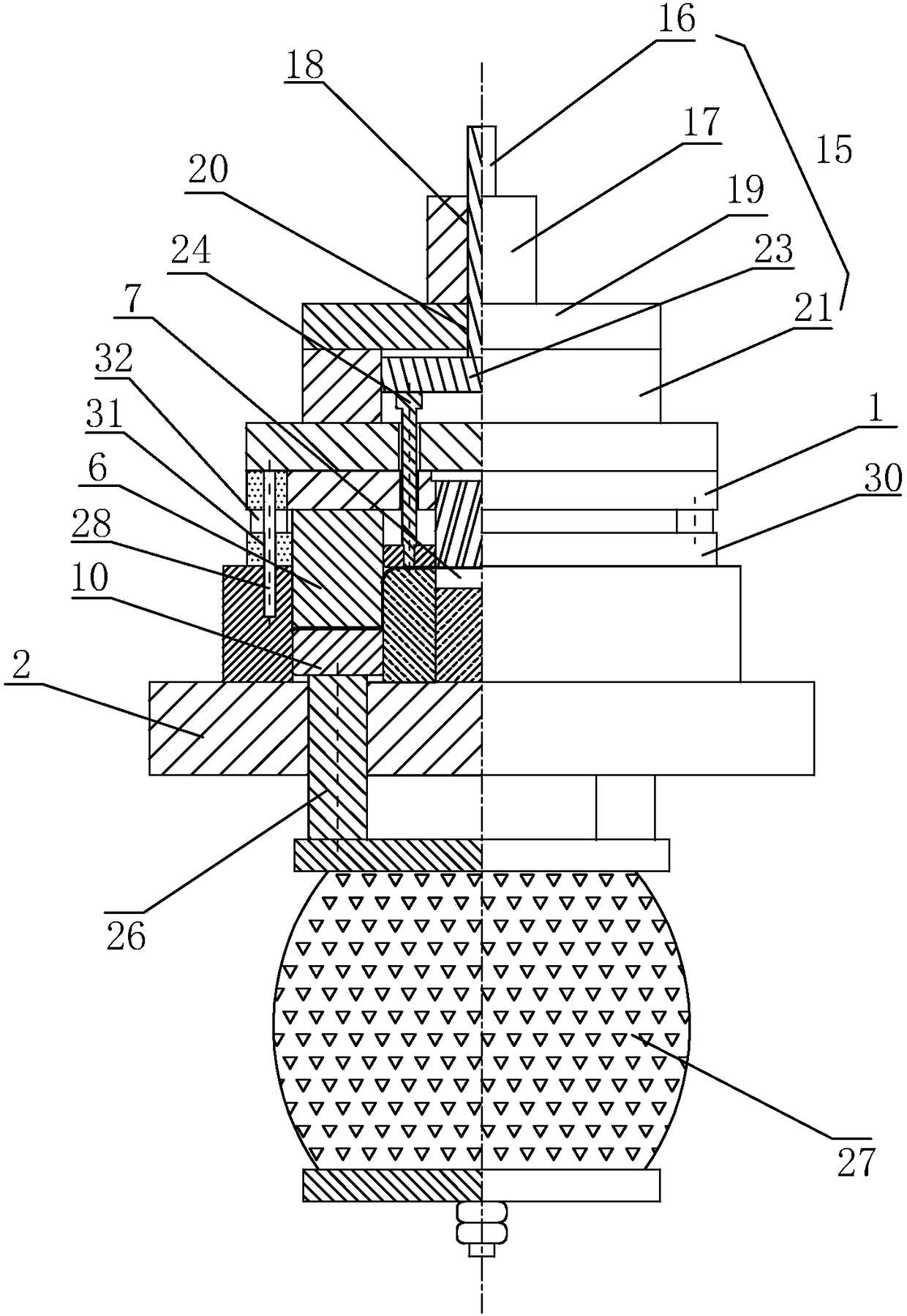

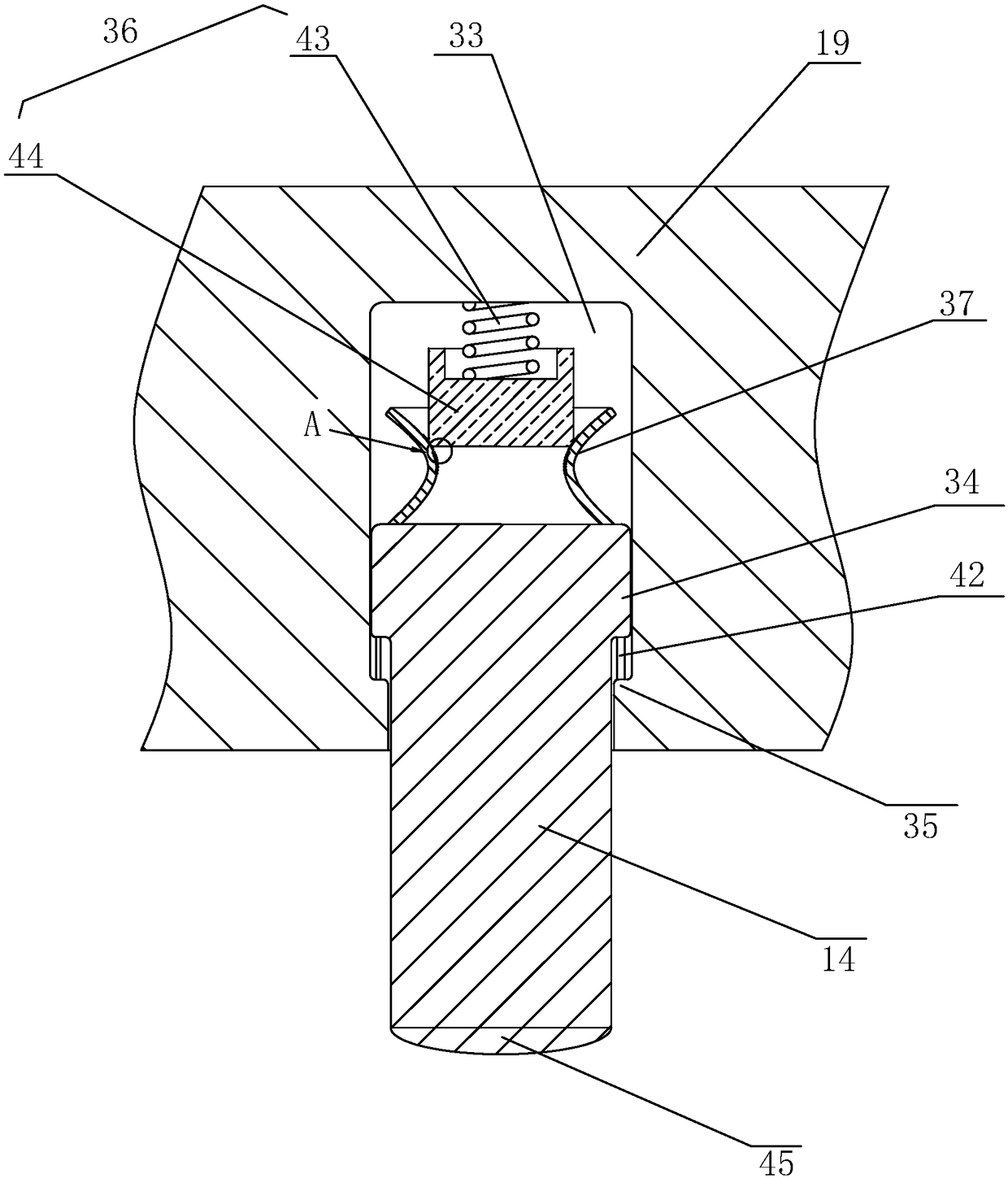

[0055] A blanking stretch punching die, combined with figure 1 with figure 2 As shown, it mainly includes an upper template 1, a lower template 2 and a stretch punching assembly 3.

[0056] Wherein, the stretch punching assembly 3 includes: a stretching die set 4, a pressing die set 8, a punching die set, and a driving part.

[0057] The driving member includes a driving device and a transmission module 15 arranged between the driving device and the upper template 1 . The driving device drives the transmission module 15 to push the upper template 1 to move up and down.

[0058] The stretching die set 4 includes a stretching punch 5 fixedly connected to the upper end surface of the lower template 2 and a stretching die 6 fixedly connected to the upper template 1 . The stretching punch 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com