Square-pole screw

A screw and main body technology, applied in the field of square halberd screws, can solve the problems of difficulty in maintaining the stability of the fracture end, instability of the fracture end, screw loosening, etc., so as to avoid the risk of fixing the retreating screw and improve the bone healing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

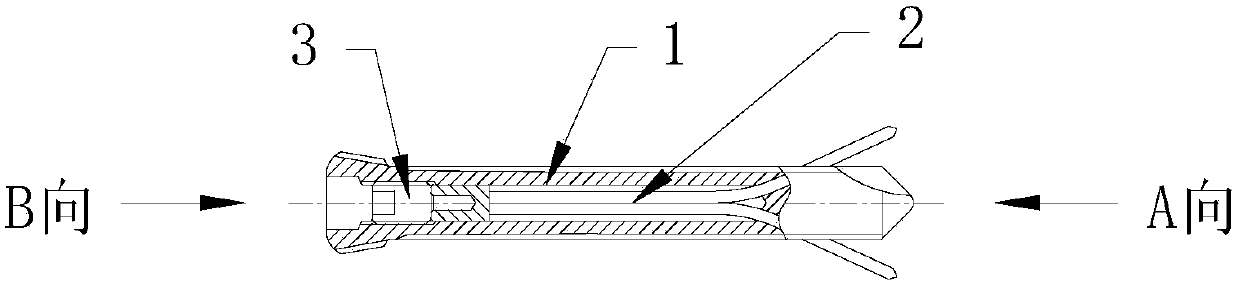

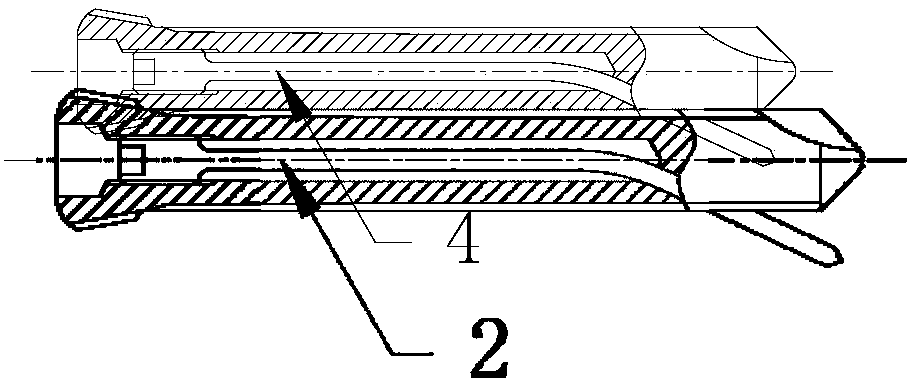

[0025] As shown in the figure, the square halberd screw provided by this embodiment includes a screw body and a fixing pin; the screw body is provided with an inner hole along the axis; the tail of the screw body is provided with an oblique hole in the axial direction; The inner holes communicate; the inner holes are provided with fixed pins matching the inner holes.

[0026] The screw body is a screw-shaped cylinder.

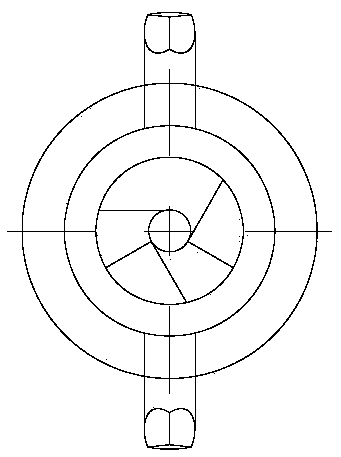

[0027] The inclined holes are arranged symmetrically at the tail of the screw body; the axial angle of the inclined holes is 20-25 degrees; the axial angle is the angle between the axial direction of the main body and the axis of the inclined holes.

[0028] The fixing pin is a single fixing pin, the head of the single fixing pin is provided with threads, and the tail is provided with a triangular pyramid.

[0029] The fixed needles are double fixed needles, and the heads of the double fixed needles are provided with internal threads; the tails are provided wi...

Embodiment 2

[0034] As shown in the figure, the square halberd screw provided in this embodiment is inserted into the screw body through a single fixation pin and directly screwed in without fixing by a nut to achieve the anti-retraction effect of the screw. The double fixation pins need to be loaded into the screw body with special instruments and the nuts should be tightened to achieve the anti-retraction effect of the double fixation screws. Square halberd screws for patients with osteoporotic fractures avoid the risk of fixing back screw, and improve the bone healing rate of patients with osteoporotic fractures

[0035] The square halberd screw provided in this embodiment includes a screw body 1, a fixing pin 2 and a nut 3; the screw body is provided with an inner hole, and two oblique holes are respectively made at an axial angle of 180 degrees at the tail of the screw body, and the oblique holes are aligned with the axis of the screw body. The inner holes are connected, the angle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com