Long-span prefabricated box girder hydraulic taking and releasing internal mould

A large-span, box-girder technology, which is applied to ceramic forming cores, ceramic forming mandrels, etc., can solve problems such as the inability to apply large-span prefabricated box beams, and achieve the effects of easy control of the retraction process, simplified operation, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical solutions, objectives and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

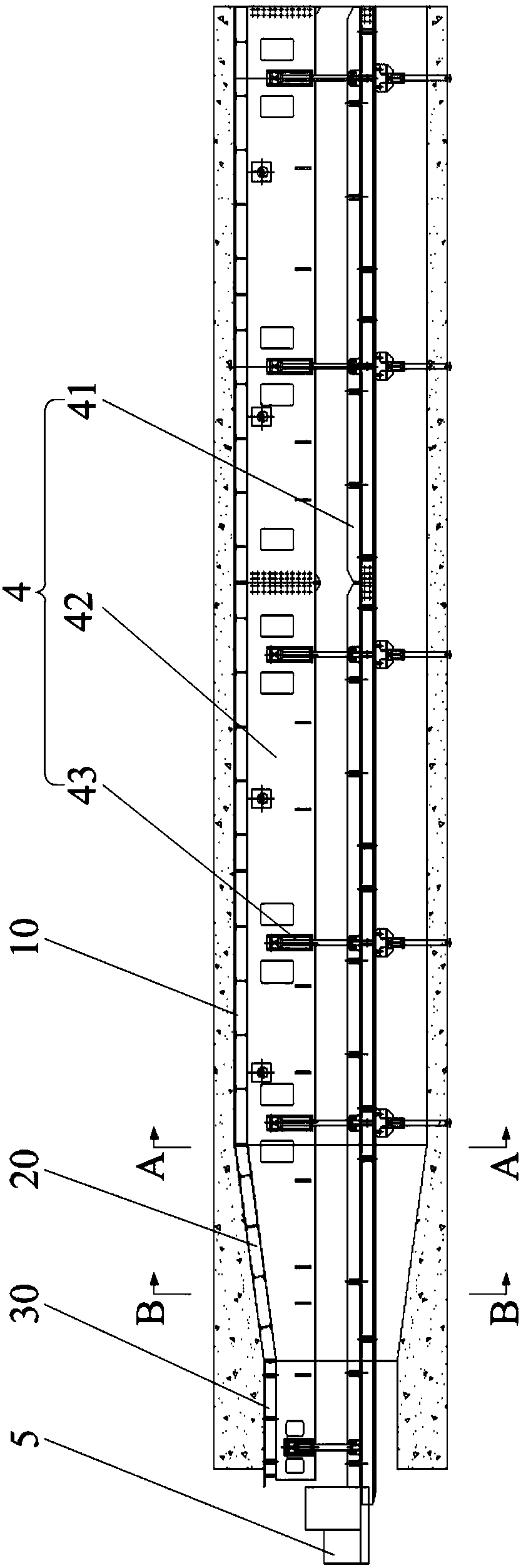

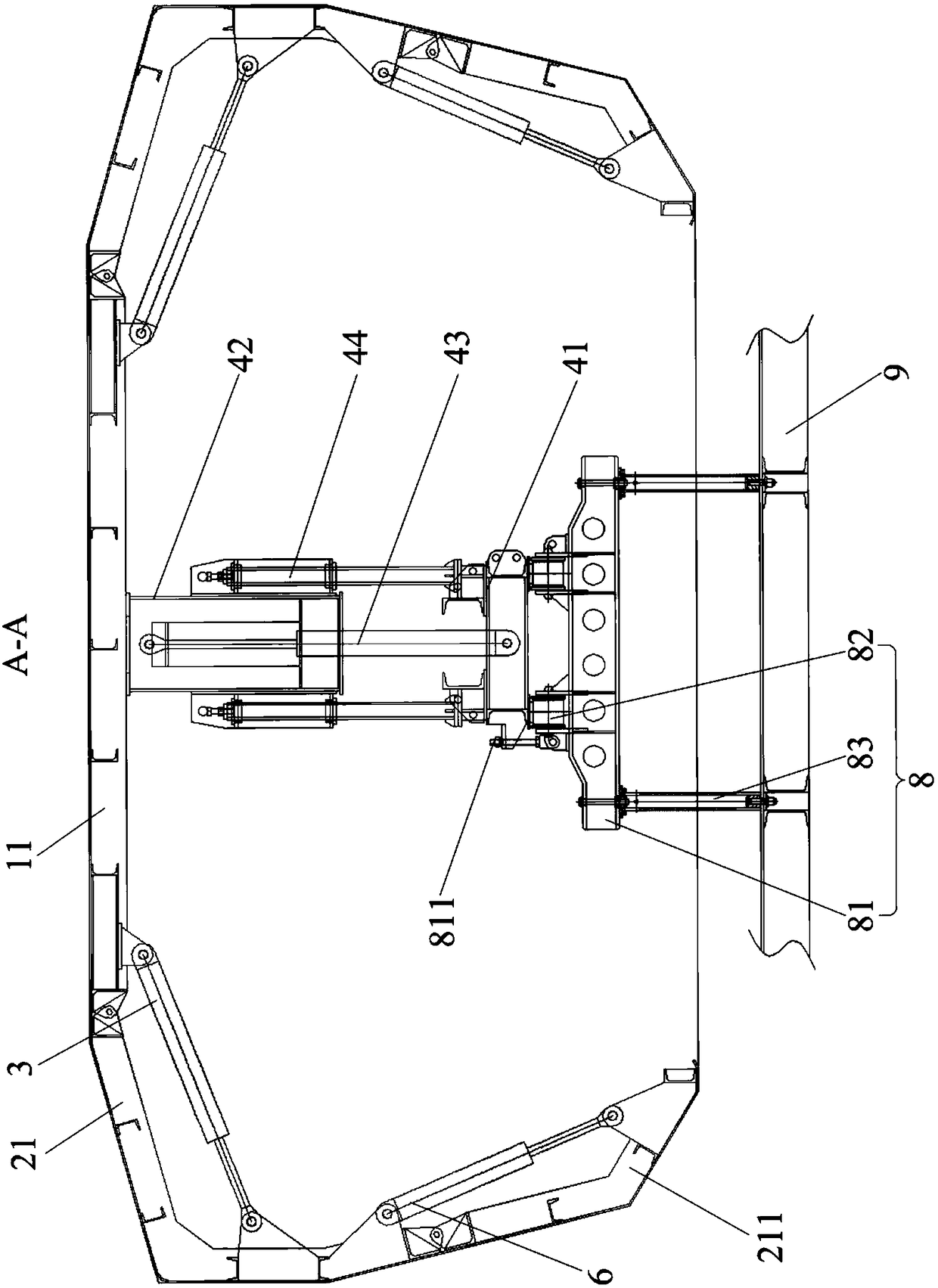

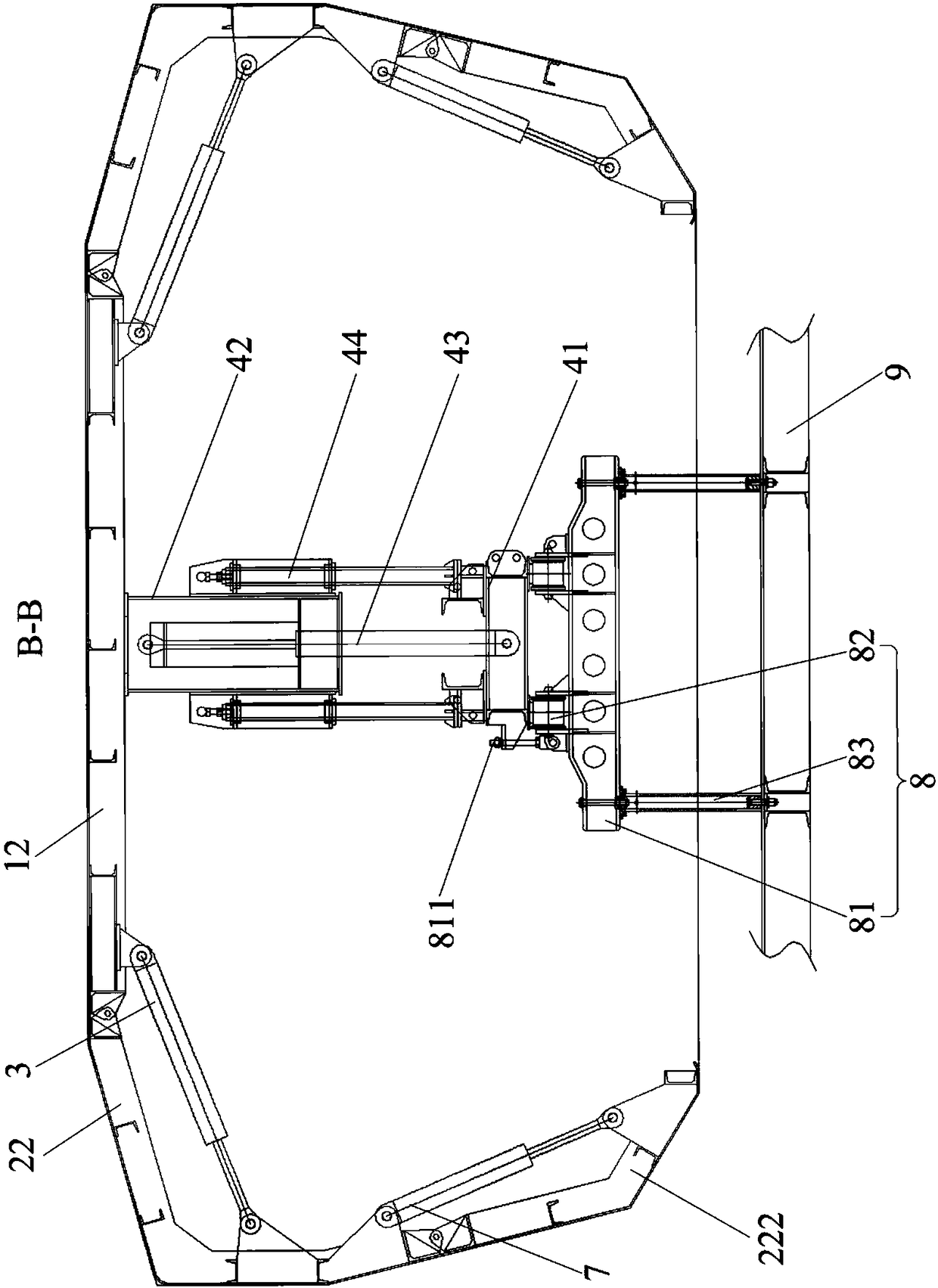

[0027] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides a large-span prefabricated box girder hydraulic retractable internal mold, specifically, a hydraulic retractable internal mold for making a large-span prefabricated box girder for a high-speed railway passenger line with a speed of 350km per hour , which includes a top mold 1 and a plurality of lifting support devices 4 arranged below the top mold 1; wherein, the two sides of the top mold 1 are respectively pivotally connected with side molds 2, specifically, the upper ends of the two sides molds 2 are rotatably connected On both sides of the top mold 1, the two side molds 2 and the top mold 1 form a hollow structure with an open bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com