Film tearing detection device

A technology of detection device and driving device, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problem of not being able to effectively detect whether the film is complete or not.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

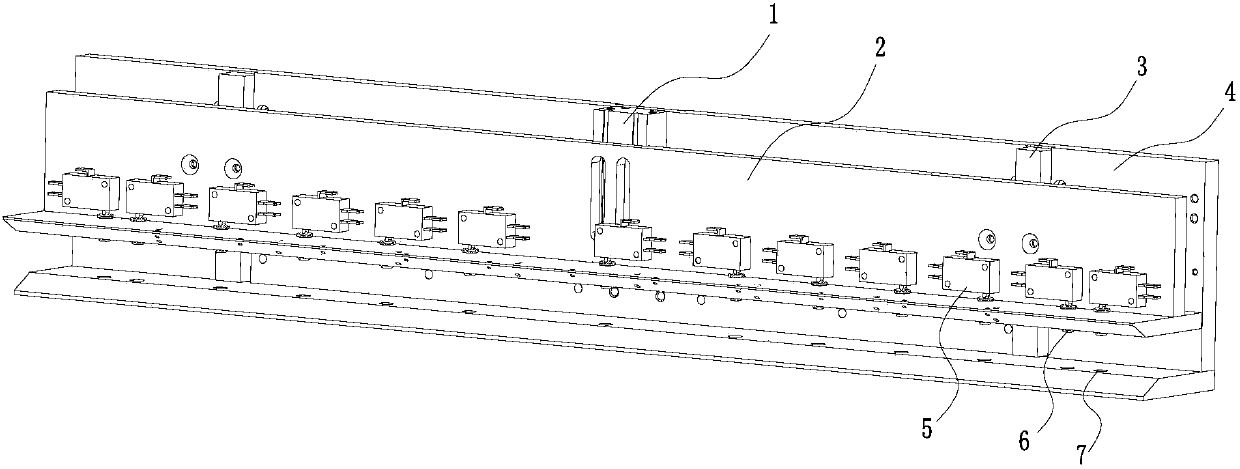

[0012] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0013] A kind of tearing film detection device of this embodiment, please refer to the attached Figure 1 to Figure 2 , including an L-shaped tearing film holder 4, the L-shaped tearing film holder 4 is provided with an L-shaped tearing film clip 2 that can slide up and down, and a plurality of light touch switches 5 are distributed and fixed on the L-shaped tearing film clip 2, Below the light touch switch 5, there are light touch extension nails 6 protruding downward from the L-shaped tearing film clamp 2 horizontal plate faces. The through hole 7 for free passage.

[0014] The L-shaped film tearing clip 2 of this device is set in the L-shaped film tearing frame 4 and can slide up and down, and then the L-shaped film tearing clip 2 is used to move up and down to realize the film clamping action, and the L-shaped film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com