Spiral steel pipe shape adjusting auxiliary system and auxiliary shape adjusting method

A technology of spiral steel pipes and auxiliary systems, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as misalignment and seam opening, eliminate positive and negative misalignment, improve geometric contour accuracy, reduce The effect of waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

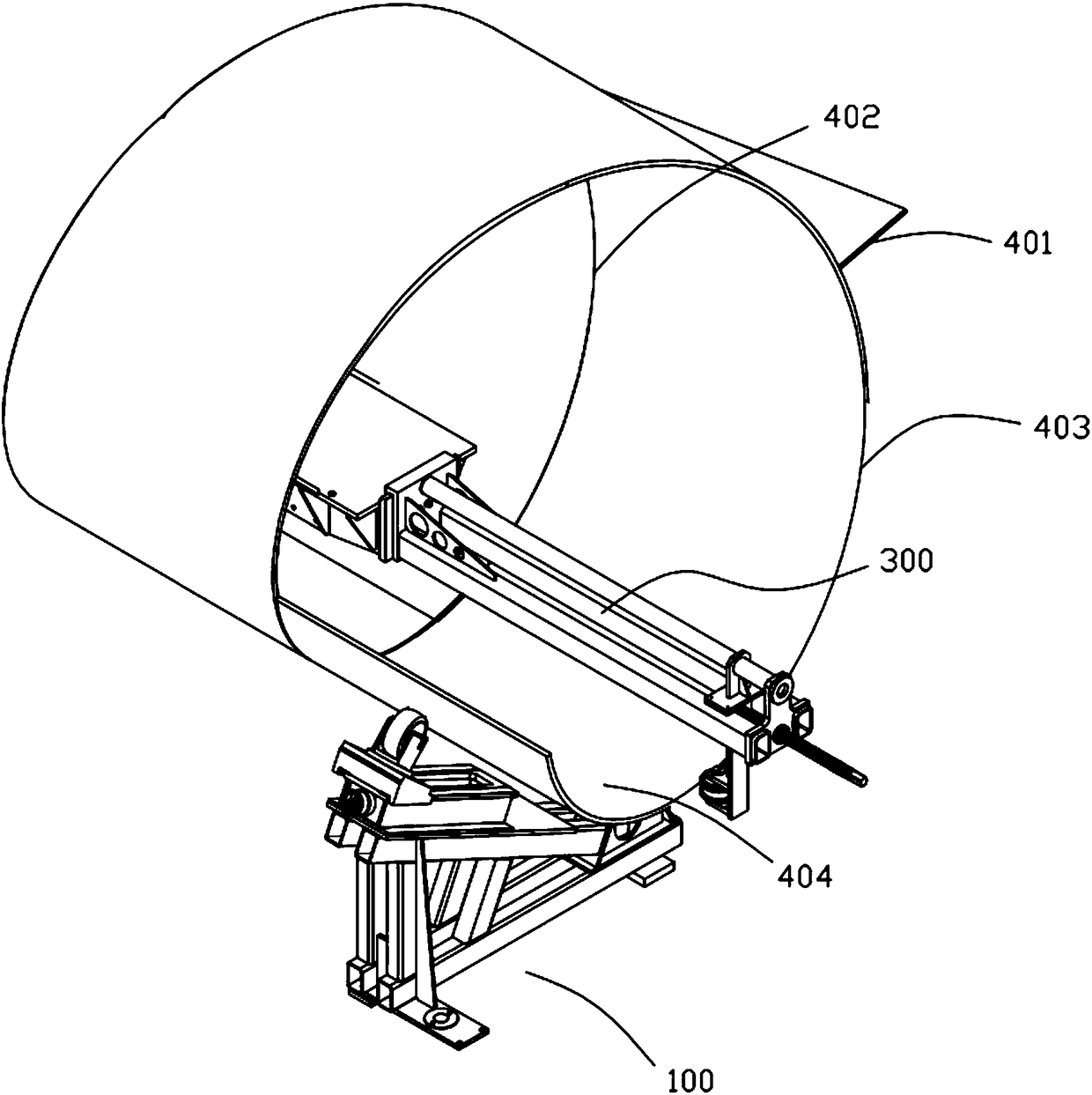

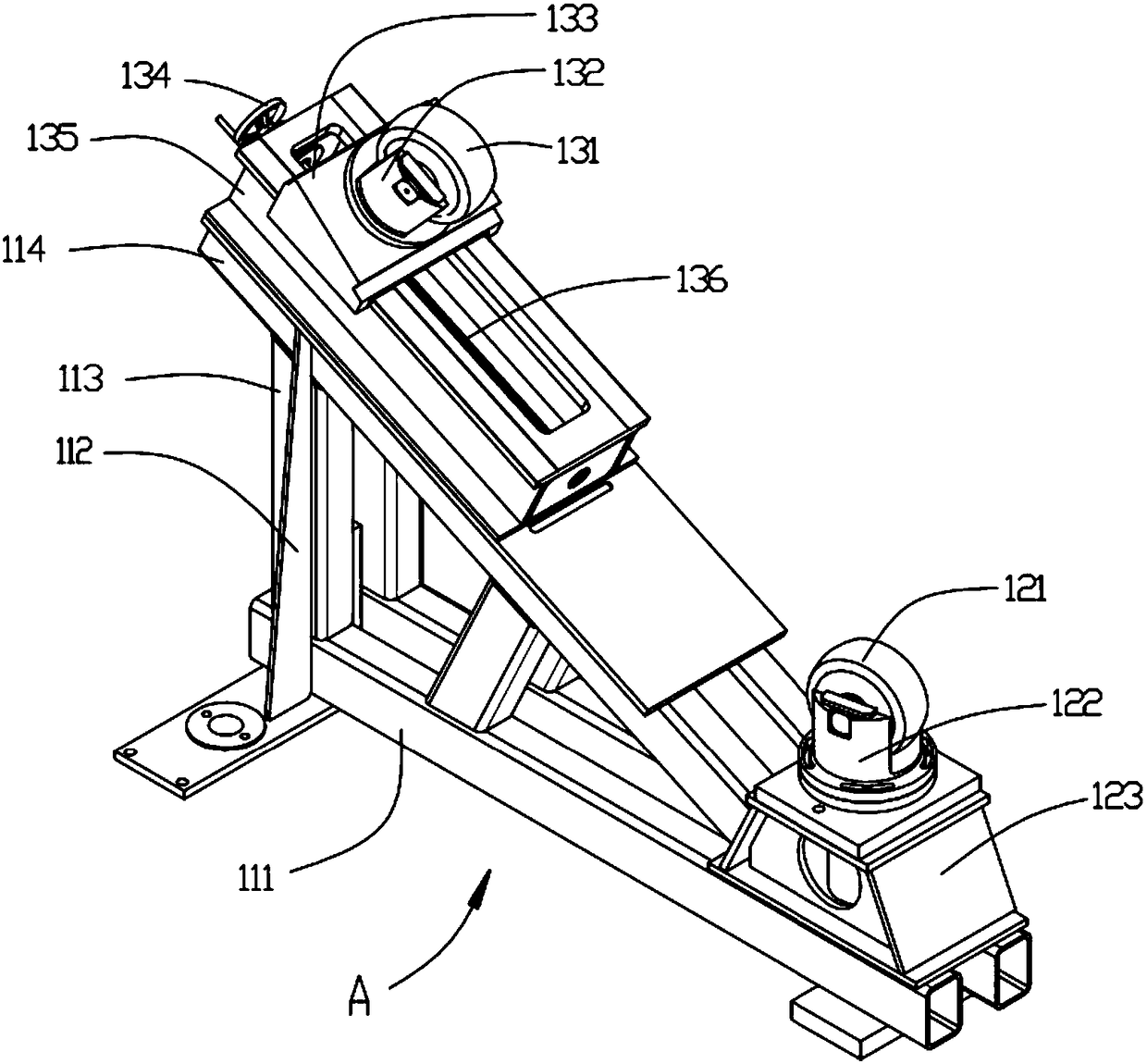

[0071] see figure 1 , the spiral steel pipe adjustment auxiliary system provided by the present invention will now be described.

[0072] The auxiliary system for adjusting the shape of the spiral steel pipe includes an outer support device 100 arranged under the head 404 of the pipe blank and a seam joint roller device 300 arranged at the head end 403 of the pipe blank. The tube blank external support device 100 includes a base and more than two outer support roller mechanisms arranged on the base, the support point of the outer support roller mechanism is attached to the outer wall of the tube blank head 404 for Supporting the pipe blank matches the design pipe diameter of the spiral steel pipe to be processed. The seaming roller device 300 includes a hanger 310, a seam roller mechanism 320 slidingly limited on the hanger 310, and drives the seam roller mechanism 320 to engage with the spiral seam of the tube blank on the hanger 310 The seaming roller translation mechanism...

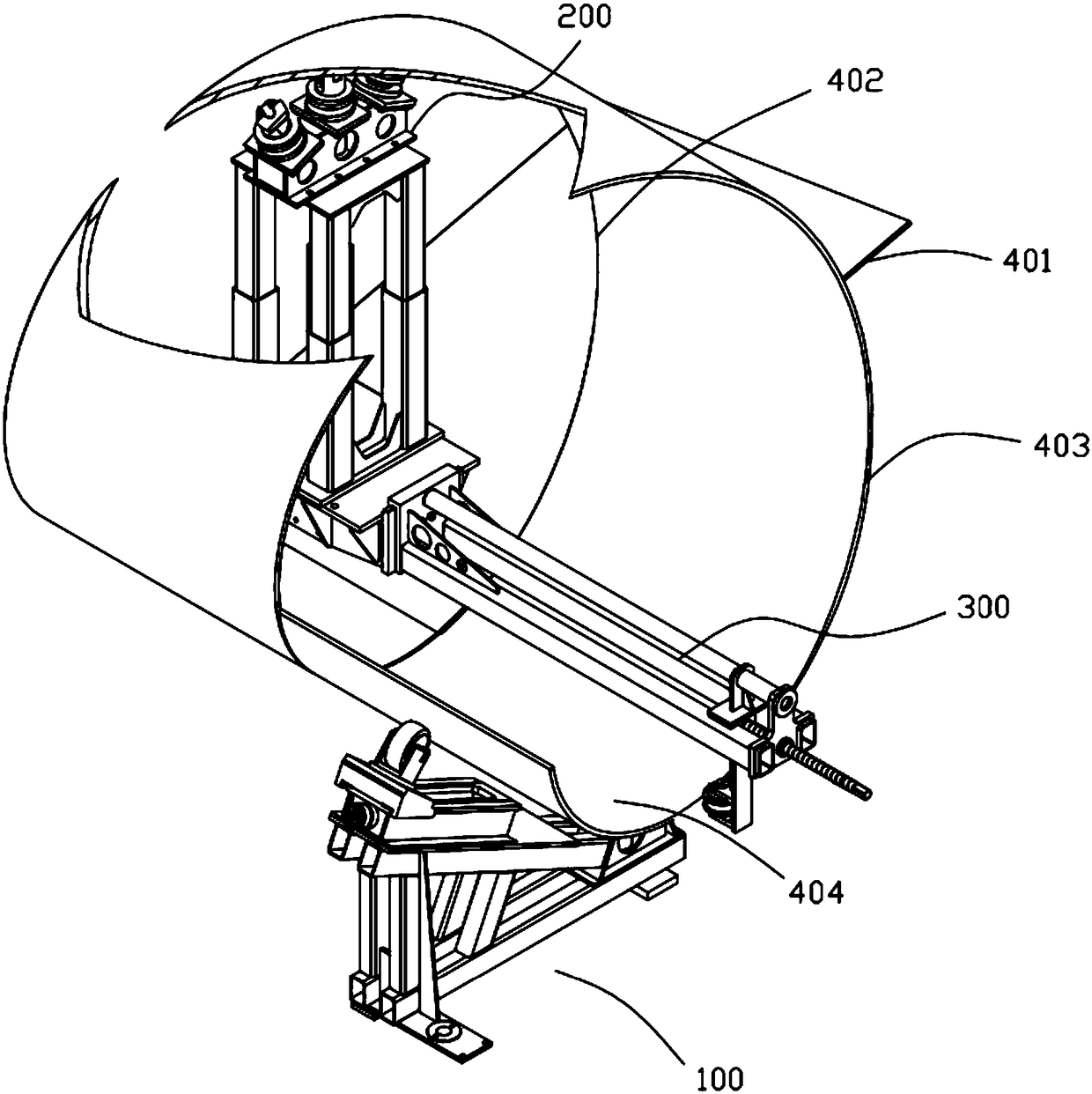

Embodiment 2

[0092] see figure 2 , in this embodiment, the spiral steel pipe shape adjustment auxiliary system includes the pipe blank outer support device 100 arranged under the pipe blank head 404, the pipe blank seaming roller device 300 that limits the pipe blank head end 403, and supports the pipe blank The inner supporting device 200 of the tube blank of the top wall. The tube blank outer support device 100 includes a base and more than two outer support roller mechanisms arranged on the base, the support point of the outer support roller mechanism is attached to the outer wall of the tube blank head 404, and is used to support the tube blank. The tube blank matches the design diameter of the spiral steel pipe to be processed. The seam joint roller device 300 includes a hanger 310 , a seam joint roller mechanism 320 slidingly limited on the hanger 310 , and drives the joint seam roller mechanism 320 to spiral toward the tube blank on the hanger 310 . The seam meshing roller transl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com