Guide vane feedback fault judgment logic method

A logic method and fault judgment technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., which can solve the problems of power fluctuation of the unit, loss of control of the guide vane, and the inability to switch the feedback signal of the guide vane to the backup sensor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

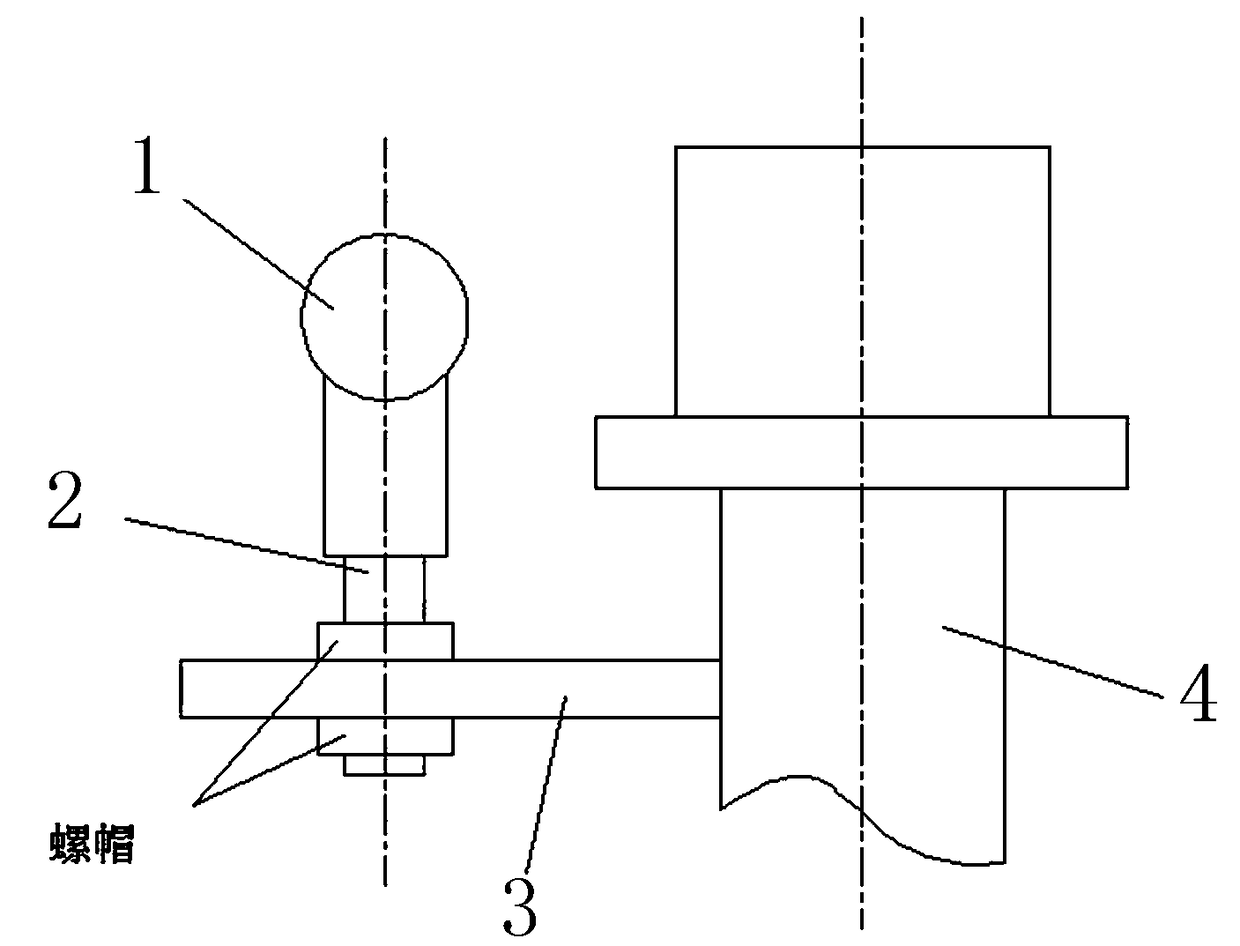

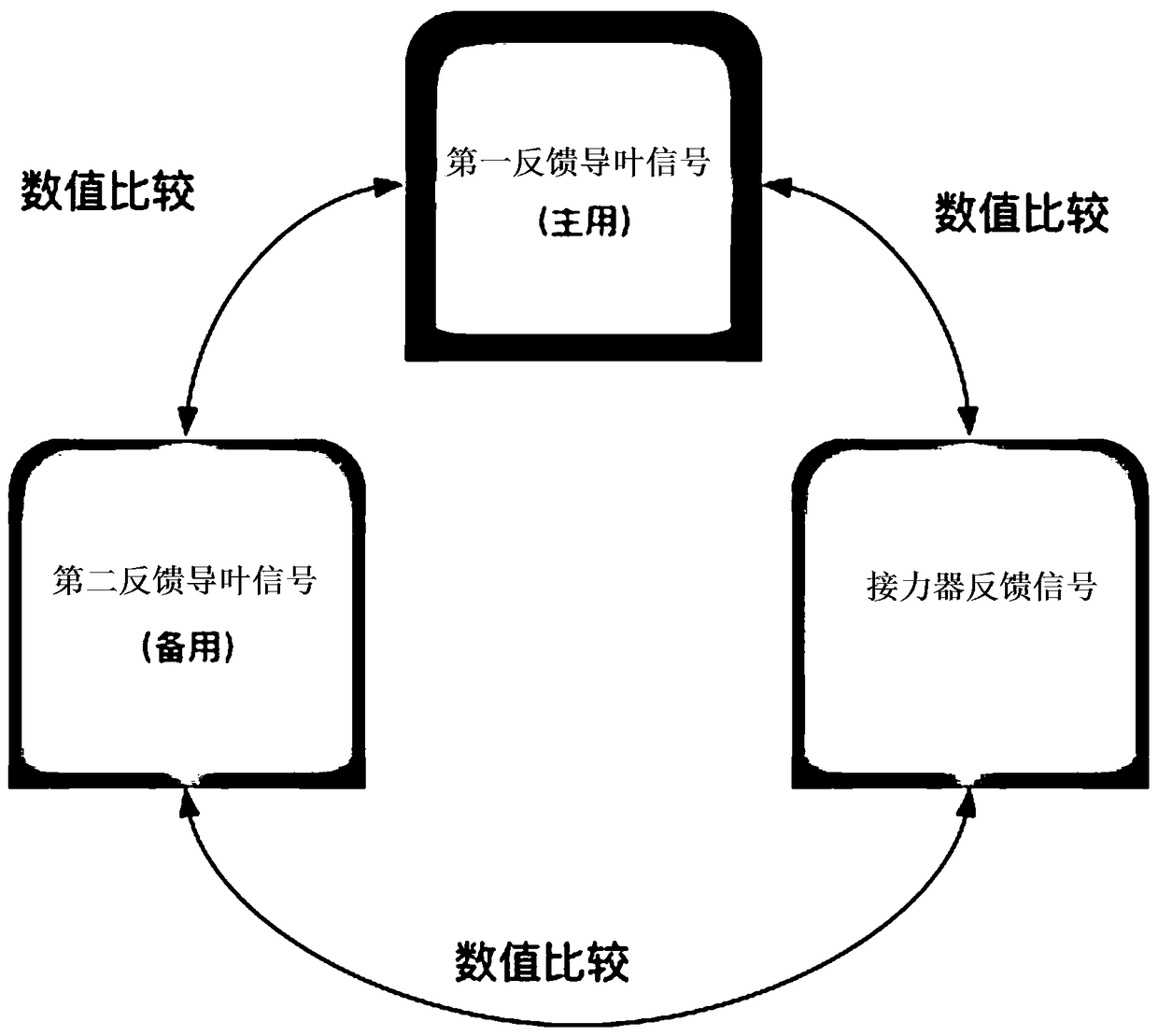

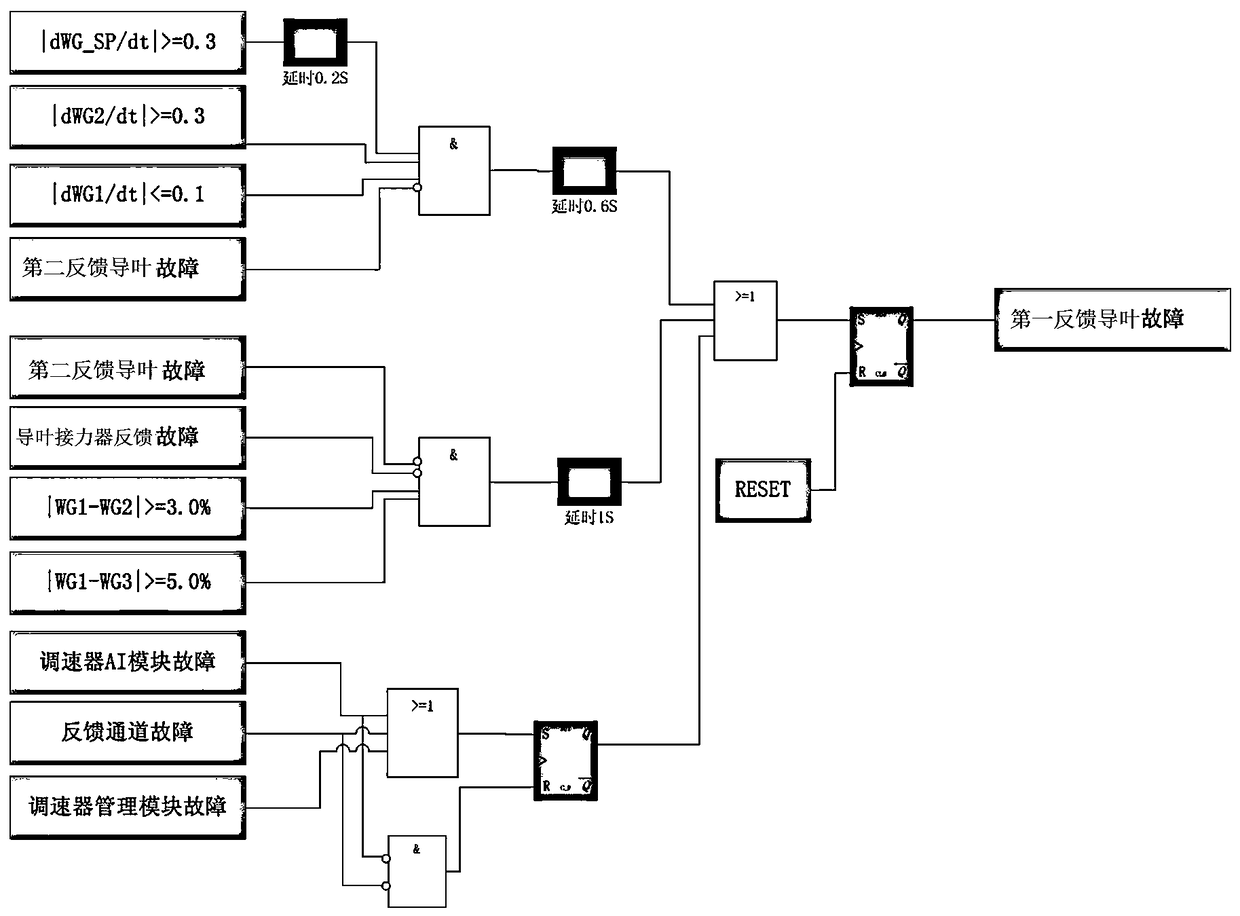

[0042]When the sensor slider of the first feedback guide vane is broken or the nut falls off, so that the guide vane displacement sensor of the first feedback guide vane cannot correctly feed back the guide vane information to the feedback channel, when the turbine is running, the feedback channel detects that the guide vane If the leaf calculation value and the feedback of the second feedback guide vane change but the feedback of the first feedback guide vane does not change, it is considered to be consistent with the fault logic of the first feedback guide vane (main) and an alarm is issued.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap