Automatic sock sleeving device for sock shaping machine

A setting machine, automatic technology, applied in the direction of setting/stretching endless fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of unsatisfactory effect, waste of time and other problems, and achieve the effect of high degree of automation and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

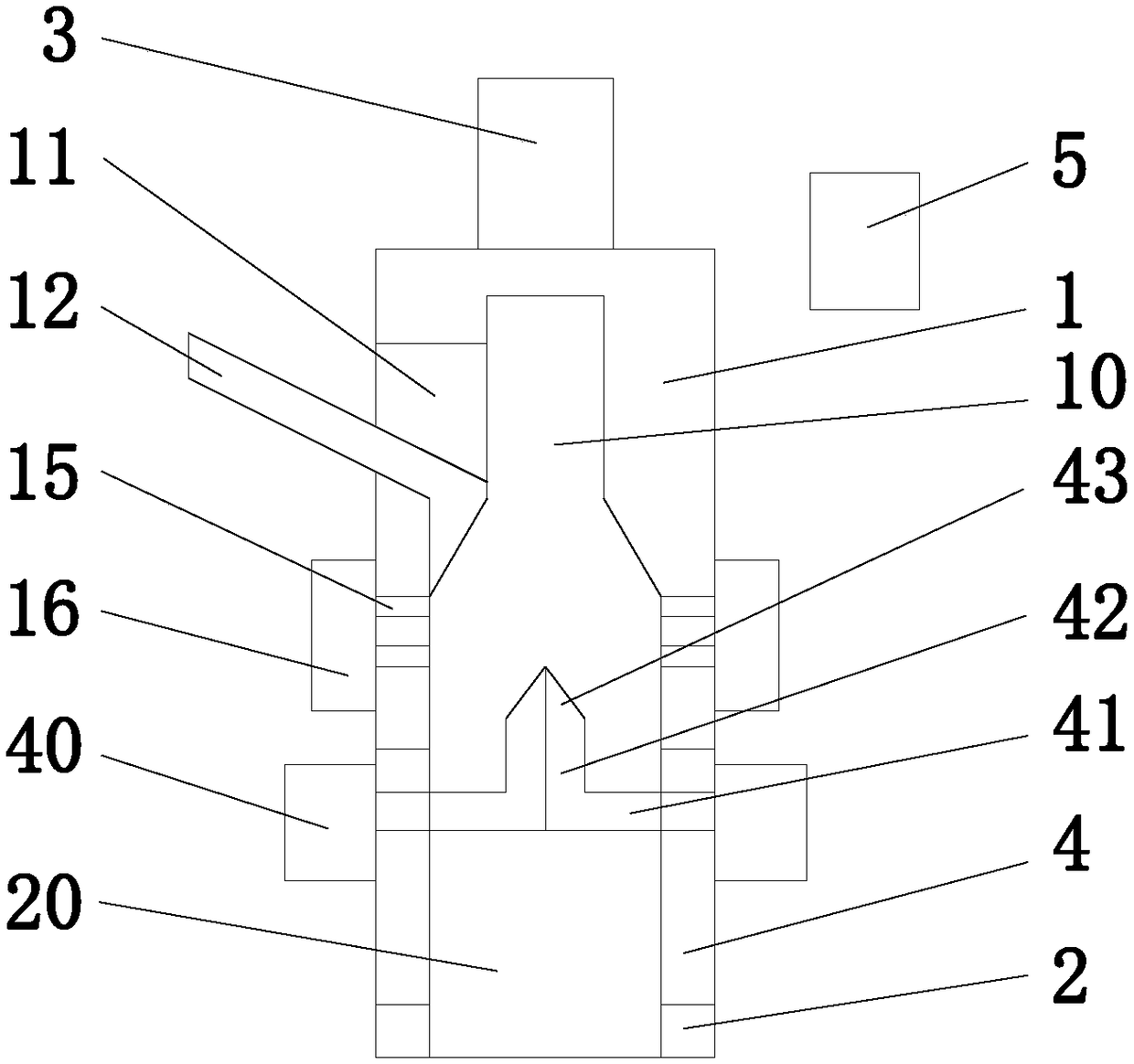

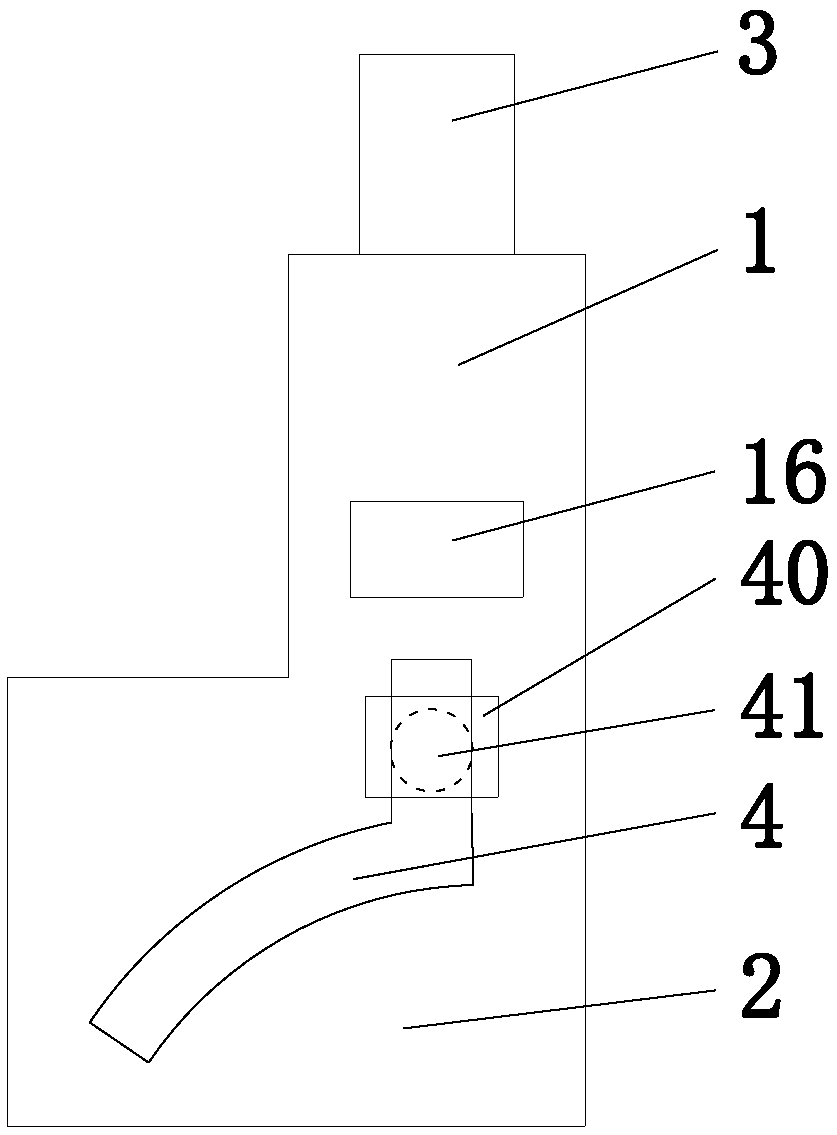

[0016] refer to figure 1 and figure 2 , the present invention is an automatic sock-setting device for a sock setting machine, comprising a sock-in tube 1, a sock-set tube 2, a lifting device 3, a walking motor 40, a guide groove 4, and a control device 5, and the sock-in tube 1 is an opening facing The lower flat cylindrical structure has a flat sock drop cavity 10 inside the sock tube 1, and a lifting device 3 is fixed on the top of the sock tube 1, and a large-area side wall of the sock tube 1 is provided with A sock inlet 11, on which a guide plate 12 inclined downward toward the inside of the sock tube 1 is fixed, and several air suction ports 15 are provided on the two large-area side inner walls of the sock tube 1, The bottom of the sock tube 1 is fixed on the top of the sock tube 2, and the sock tube 2 has a flat tubular structure with an opening downward. There is a flat sock cavity 20 inside the sock tube 2, and the sock drop cavity 10 Connected with the sock cavit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com