An intelligent vehicle exhaust pipe detection device

A technology for exhaust pipes and detection points, which is applied in the field of intelligent exhaust pipe detection devices, can solve the problems that cannot adapt to the development trend of digital factories, cannot digitally collect quality inspection results, and cannot realize lean management of production lines, so as to reduce the cost of missed inspections Probability, reduction of production costs, and the effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

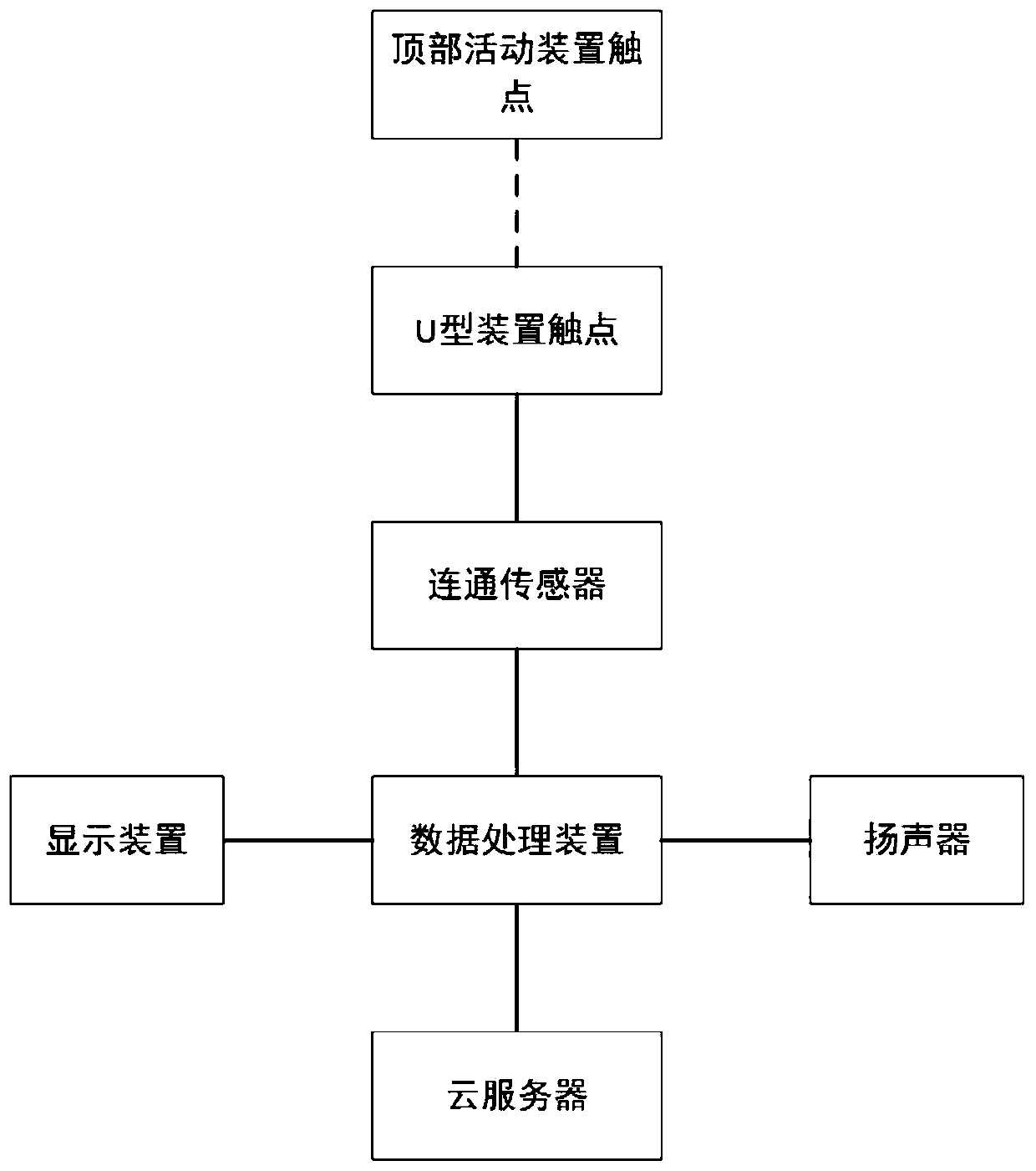

[0022] The invention proposes an intelligent exhaust pipe detection device, which includes a base and a plurality of detection points;

[0023] The detection point is fixed on the base according to the three-dimensional structure of the exhaust pipe;

[0024] Detection points include U-shaped base and top movable device;

[0025] The first end of the top movable device is twisted and connected with the first end of the U-shaped base, and the second end of the top movable device is provided with two contacts, the two contacts are connected by a conductor, and the contacts are covered with insulating materials;

[0026] The two contacts are connected by a conductor and covered with insulating material around them to ensure that only when the top movable device and the U-shaped base are fully closed, the two contacts will be conducted, thereby triggering the connection sensor.

[0027] The second end of the U-shaped base is provided with two contacts corresponding to the second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com