Unidirectional heat dissipation module

A heat dissipation module and one-way technology, applied in the direction of modification through conduction heat transfer, cooling/ventilation/heating transformation, electrochemical generator, etc., can solve the problem of increasing the power of lithium battery heating, failing to meet the use requirements, and affecting Battery power, battery life and lifespan issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

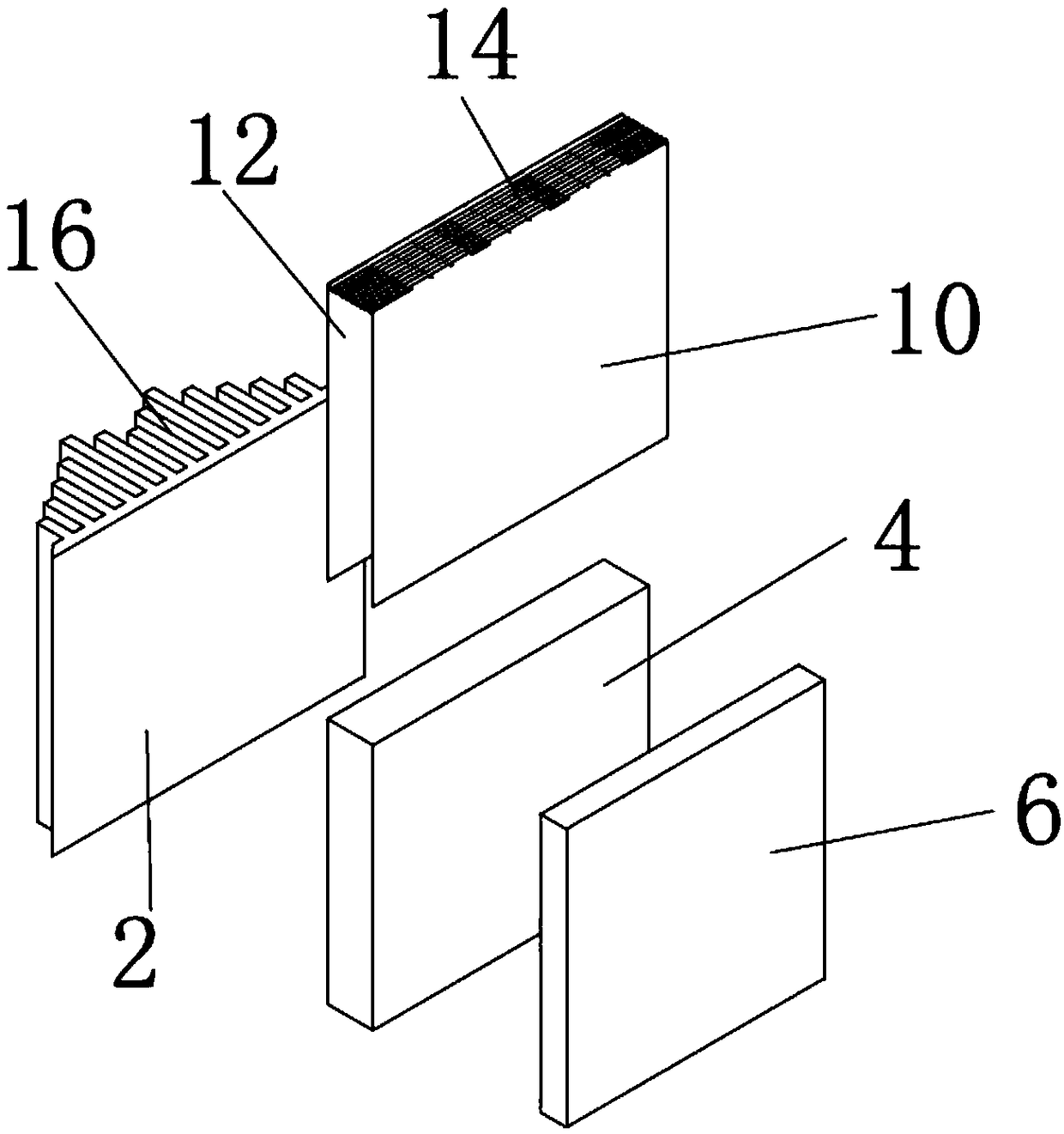

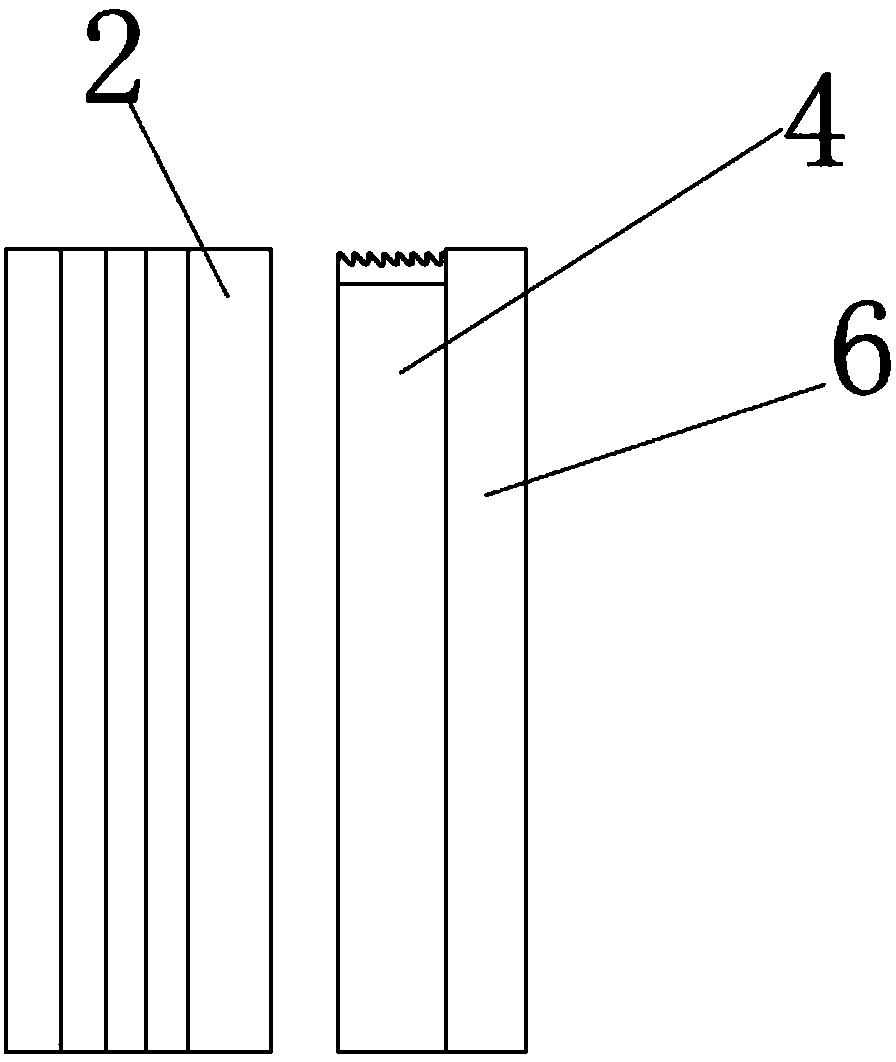

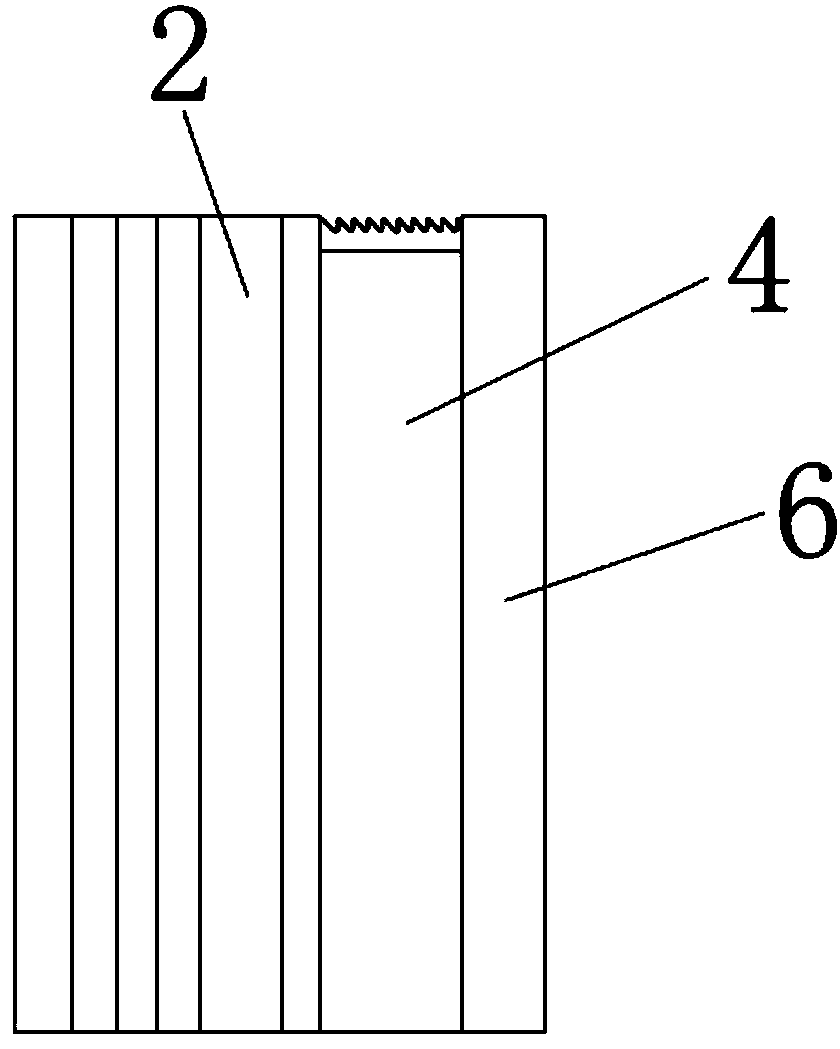

[0022] Such as Figure 1-3 As shown, this embodiment discloses a one-way heat dissipation module, including a radiator 2 and a two-way memory connector 4, the above-mentioned two-way memory connector 4 is arranged close to the heat source 6, and is arranged between the heat source 6 and the radiator 2 Between, the above-mentioned two-way memory connector 4 can memory expansion and memory contraction, when the above-mentioned two-way memory connector 4 memory expands, it connects the heat source 6 and the radiator 2, and when the above-mentioned two-way memory connector 4 memory shrinks, it separates the heat source 6 and the heat dissipation Device 2. In the technical solution of this embodiment, the two-way memory connector 4 has an expansion critical temperature and a contraction critical temperature. When the temperature of the two-way memory connector 4 exceeds the expansion critical temperature, the two-way memory connector 4 memory expands, and the expanded double The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com