Three-dimensional space steel tower segmental hoisting accurate positioning method based on two-dimensional line shape

A precise positioning and three-dimensional space technology, which is applied in the erection/assembly of bridges, buildings, bridge construction, etc., can solve the problems of steel tower double-check measurement ineffectiveness, difficult alignment accuracy requirements, and large errors, so as to improve the efficiency of positioning construction , improve the accuracy of the linear shape, the effect of a wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

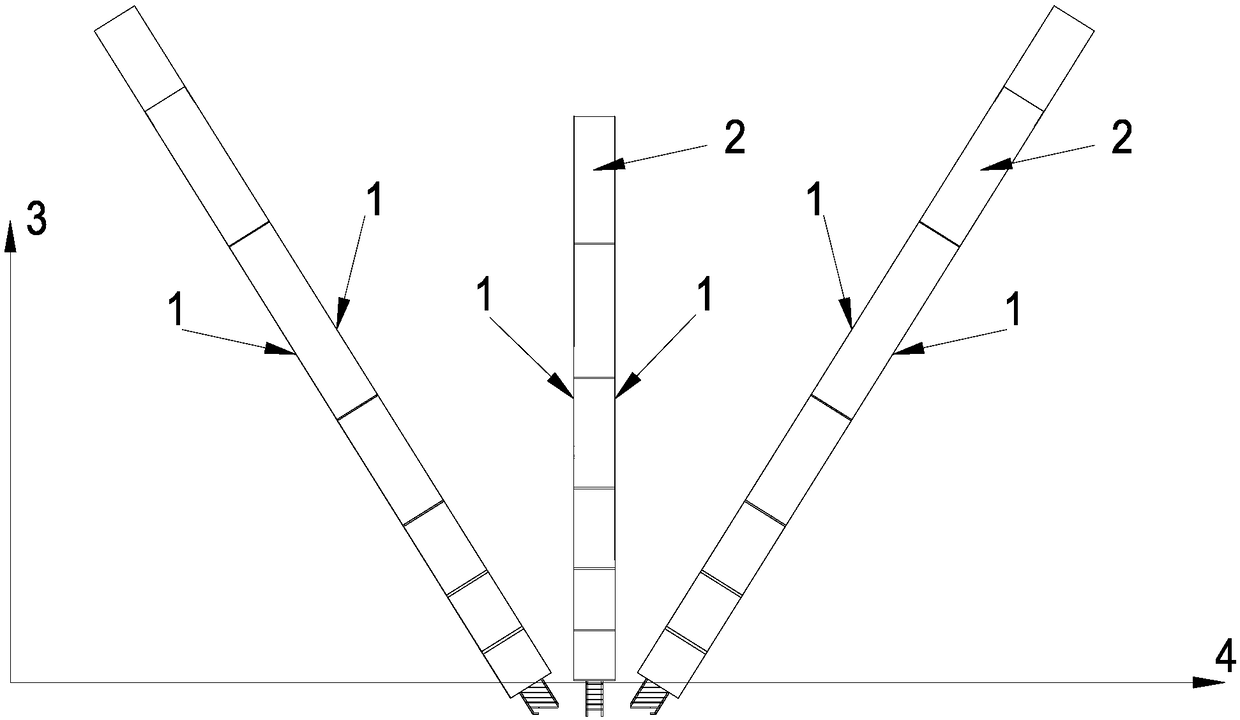

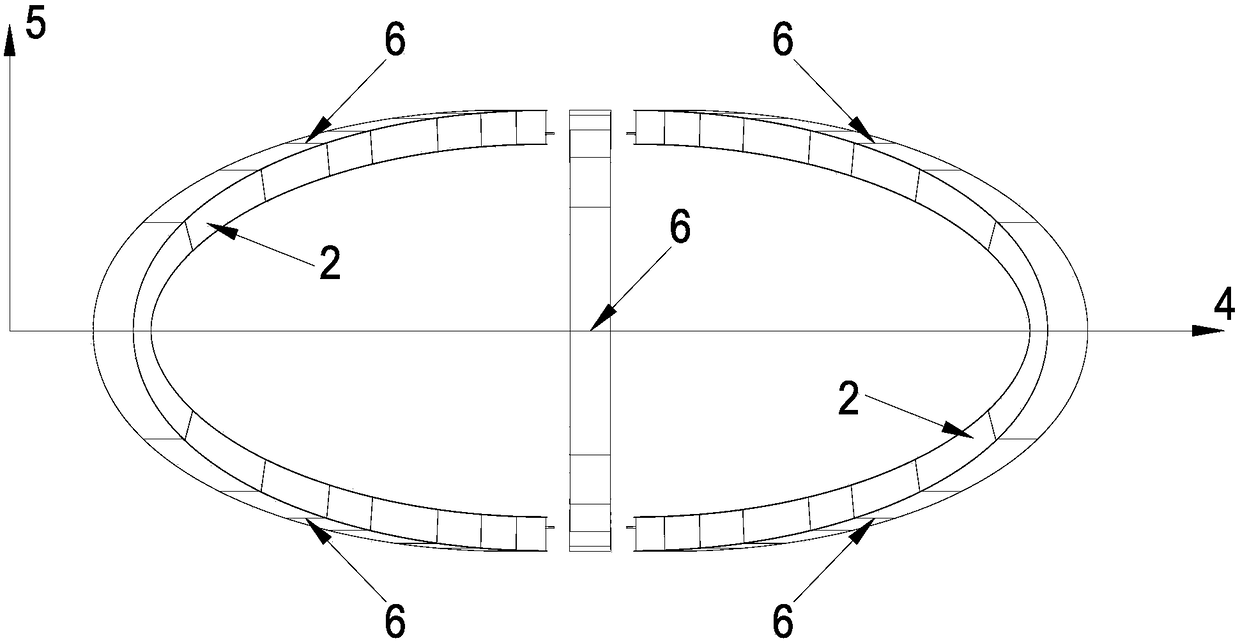

[0028] refer to Figure 1 to Figure 3 , in this preferred embodiment, a three-dimensional space steel tower segmental hoisting precise positioning method based on two-dimensional alignment, comprising the following steps:

[0029] Step S10, before hoisting the steel tower segment, according to the construction design drawing of the steel tower, project the steel tower according to the side elevation and the horizontal plane respectively, to obtain the two-dimensional alignment of the elevation and the two-dimensional alignment of the horizontal plane;

[0030] Step S20, respectively importing the linear elements of the two-dimensional linear shape of the facade and the two-dimensional linear shape of the horizontal plane into the total station, so as to realize the replacement of body by surface, and the replacement o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com