A positioning structure of a bridge frame and its positioning construction method

A technology for positioning structures and bridges, applied in bridge construction, bridge erection/assembly bridges, etc., can solve problems such as difficult construction and limited construction space, and achieve the effects of increasing construction difficulty, improving construction efficiency, and realizing deviation adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

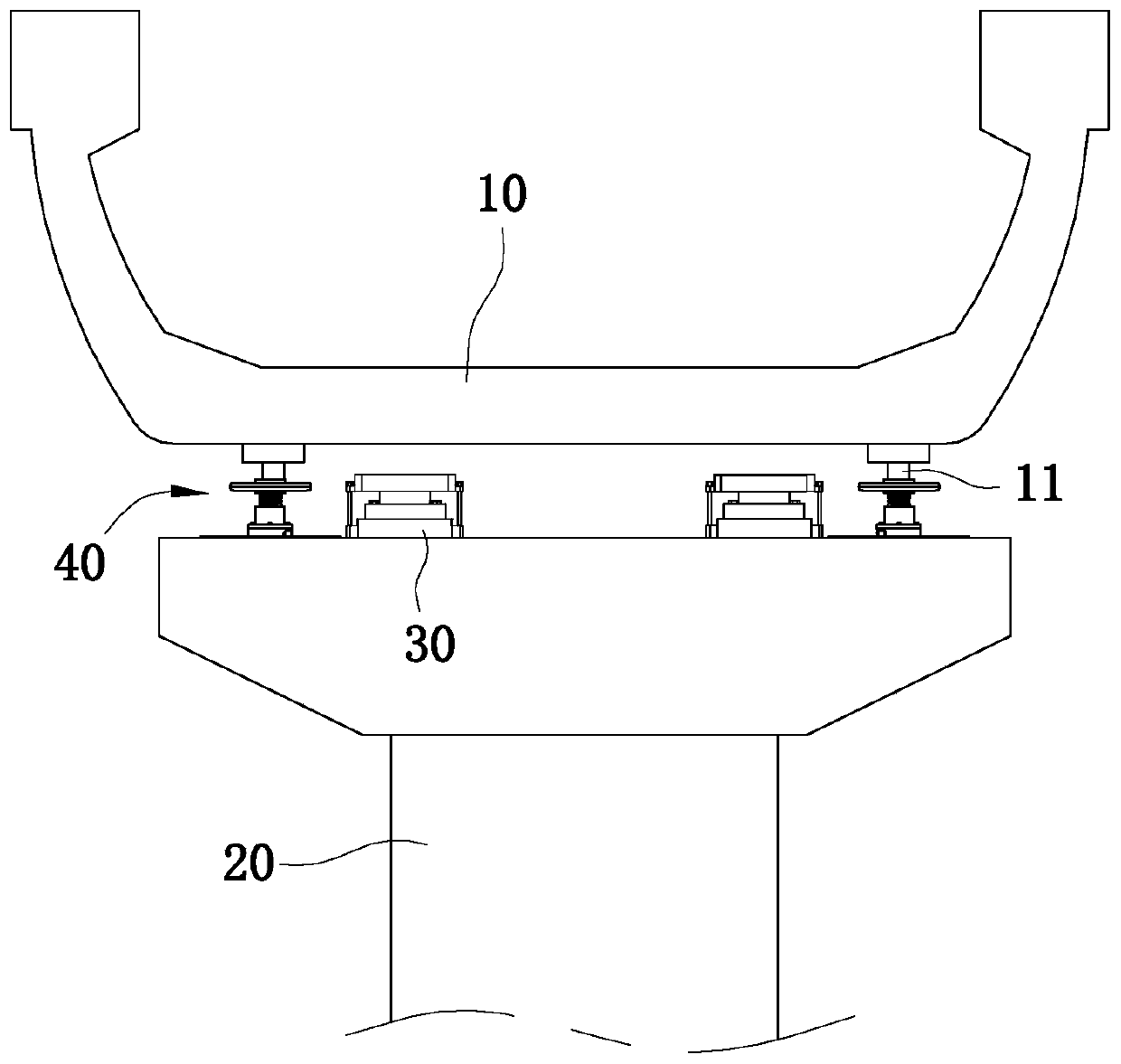

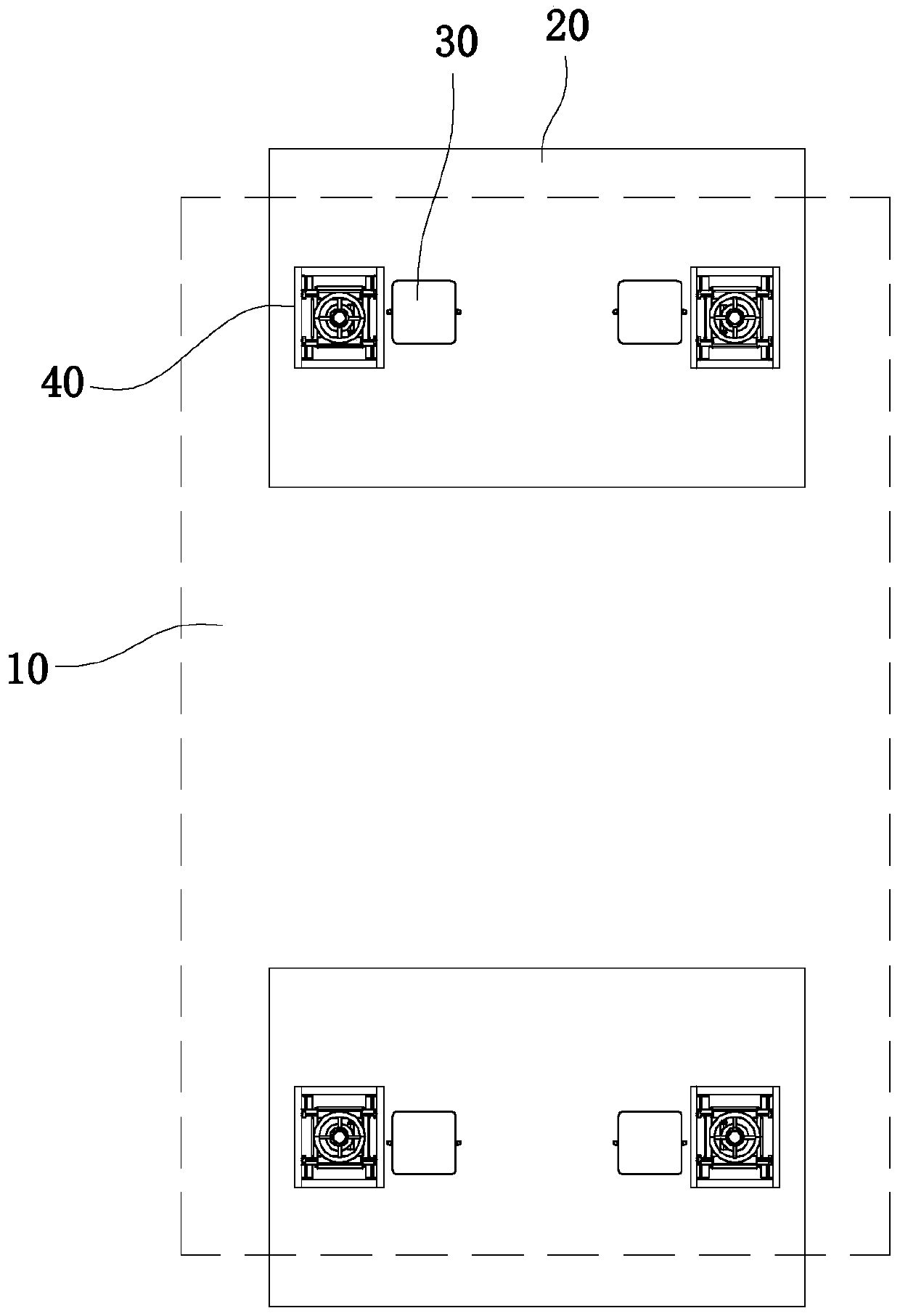

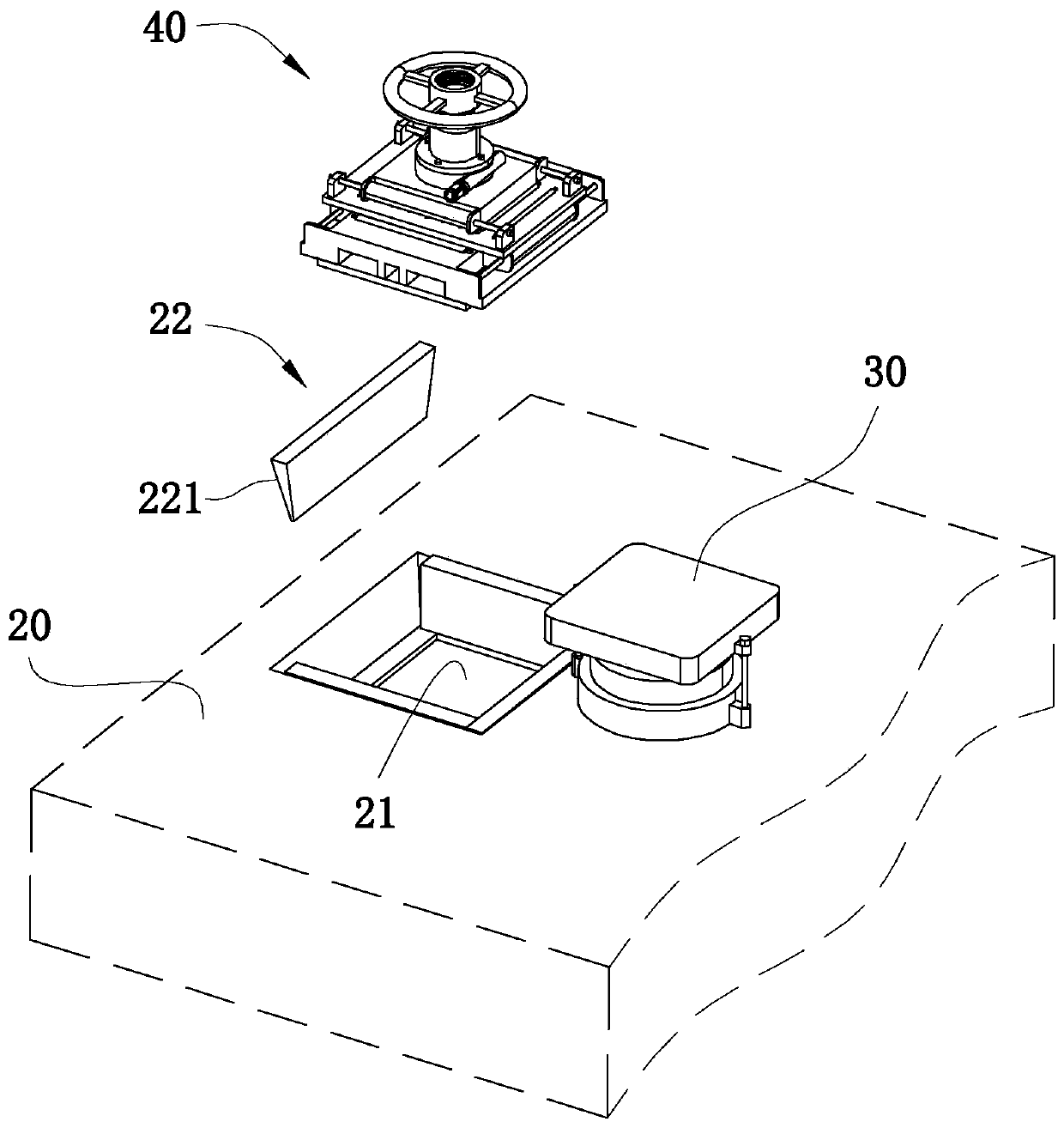

[0040] Common reference of embodiment one figure 1 and figure 2 , a bridge frame setting and positioning structure, including a bridge pier 20, a prefabricated beam 10 erected on the pier 20, a positioning system located above the pier 20, and a bearing 30 for supporting the prefabricated beam 10. In this embodiment, the prefabricated girder 10 is a prefabricated U-shaped girder, and of course it is also applicable to the erection and positioning of box girders or other bridges.

[0041]The whole positioning system includes four positioning devices 40, two positioning devices 40 are respectively installed on each bridge pier 20, and the four positioning devices 40 are arranged on the two bridge piers 20 in a rectangular arrangement; in addition, each bridge pier 20 is also provided with The two supports 30 are located between the two positioning devices 40 on the same pier 20 . The bottom of the prefabricated beam 10 is provided with four prefabricated columns 11 correspond...

Embodiment 2

[0051] Embodiment 2 A positioning construction method for setting a positioning structure of a bridge frame, comprising the following steps:

[0052] Step 1: Use a crane to lift the prefabricated beam 10, and hoist the prefabricated beam 10 to the position above the middle of two adjacent piers 20, and slowly drop the beam;

[0053] Step 2: Control the horizontal movement of the prefabricated beam 10 through the crane, slowly drop the beam so that the prefabricated column 11 at the bottom is slowly aligned with the third piston rod 452 of the lifting hydraulic jack 45, and start the lifting hydraulic jack 45 to make the third piston The rod 452 extends toward the side of the prefabricated beam 10 to the maximum stroke, and continues to drop the beam until the prefabricated cylinder 11 abuts against the end of the third piston rod 452 to stop the beam falling;

[0054] Step 3: Manually rotate the connecting sleeves 47 on the third piston rod 452, so that the four connecting sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com