Pressure relief guide device for oil well wellhead

A flow diversion device and oil well technology, which is applied in wellbore/well valve devices, wellbore/well parts, earthwork drilling and production, etc., which can solve the problems of slow pressure passage, poor fluid passage capacity, and prolonged pressure release time, etc. , to achieve the effect of rapid discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing:

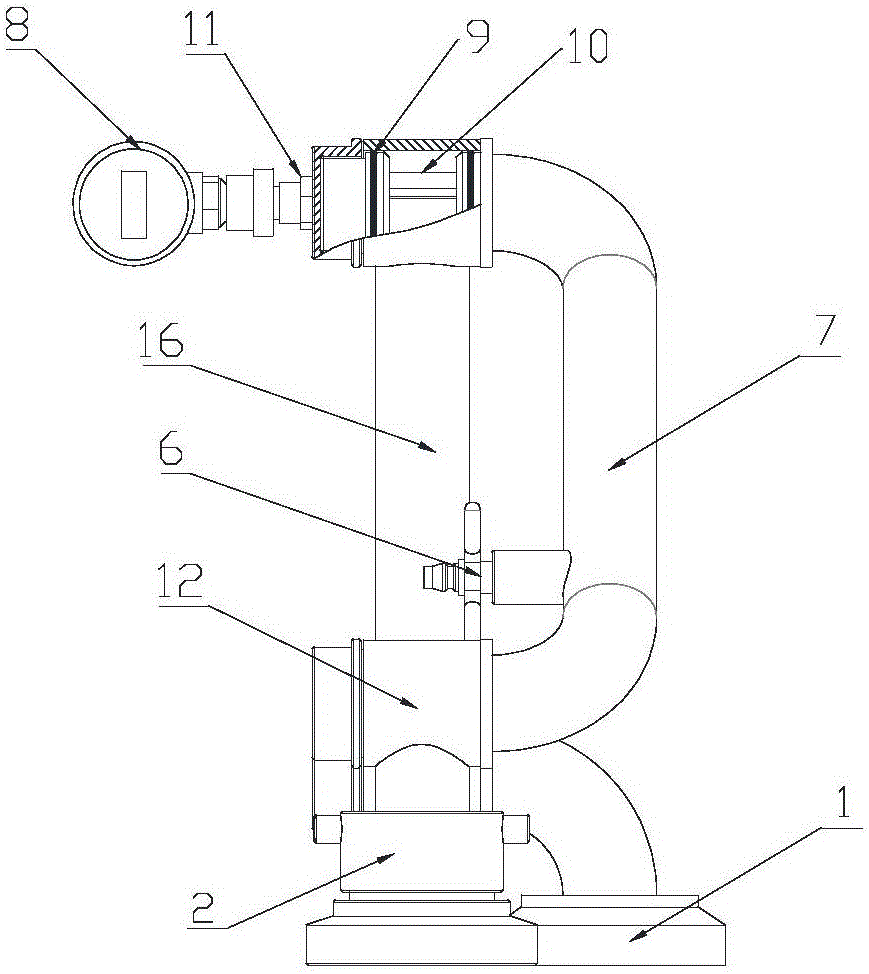

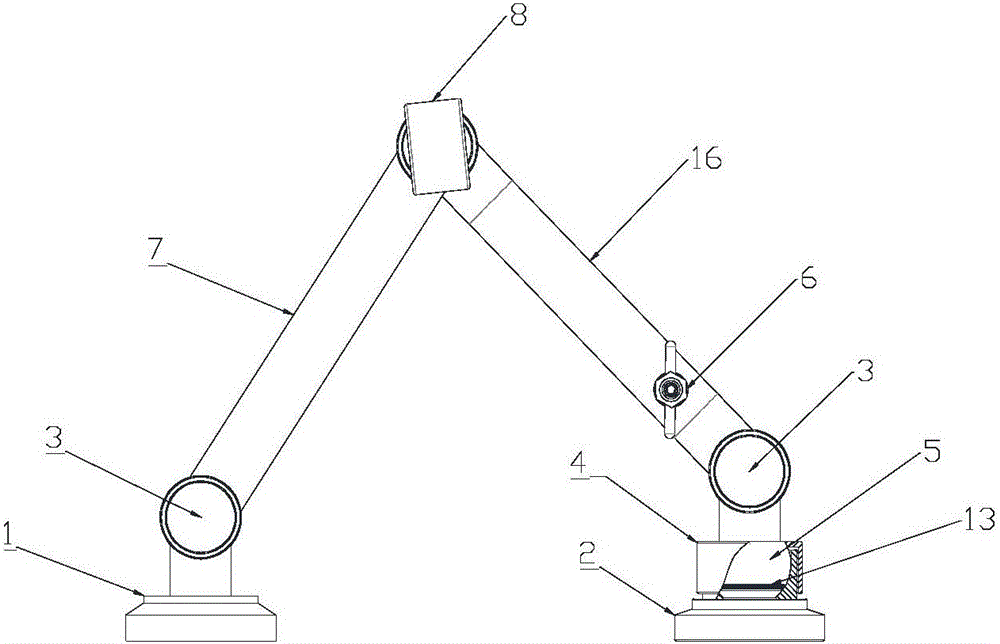

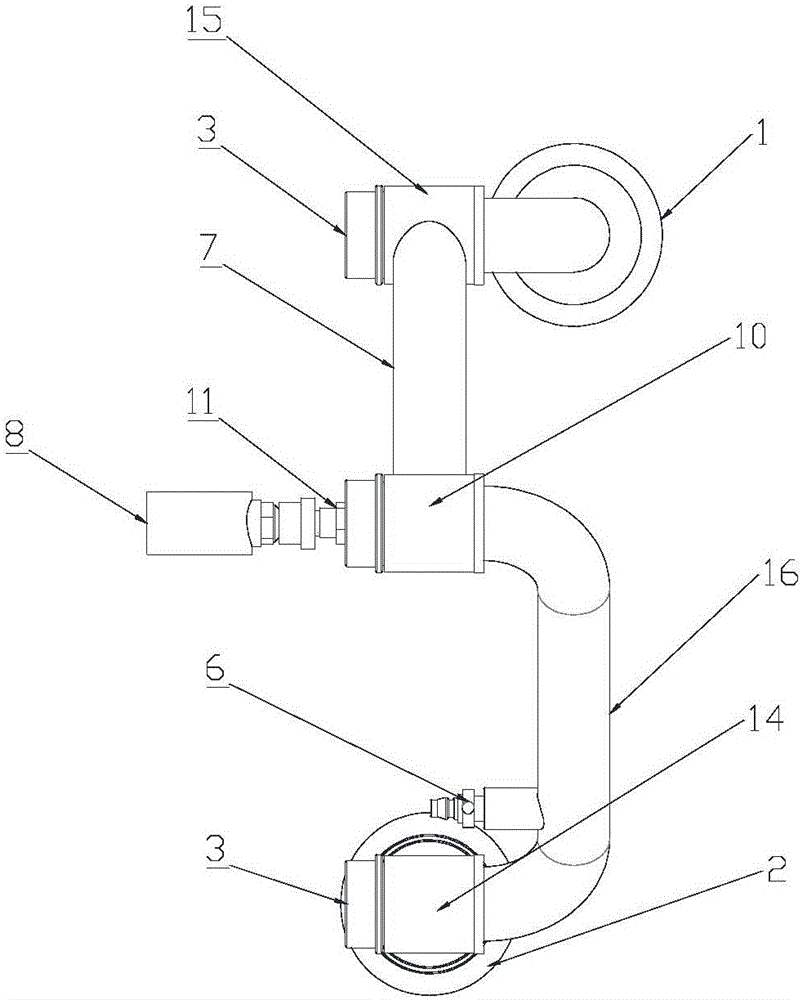

[0017] Depend on Figure 1 to Figure 5 As shown, an oil well wellhead pressure relief and diversion device includes a clamp seat 1, an elbow on the clamp seat 1 is connected to a three-width rotary joint C15, and a folded pipe is connected to the three-width rotary joint C15 through an outer jacket 12 A7, so that the folding tube A7 can freely rotate relative to the clamp seat 1. The other end of the folding tube A7 is connected to the three-width rotary joint A10 through another jacket, and the three-width rotary joint A10 is connected to the folding tube B16 through an elbow, so that the folding tube B16 and the folding tube A7 can rotate freely. The other end of the folded tube B16 is connected to the three-width rotary joint B14 through an elbow, and the other end of the three-width rotary joint B14 is connected to the deviation adjustment ball 5 through the jacket 12,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com