Abrasion-resistant efficient noise-damping circular saw blade

A sound-absorbing saw blade, high-efficiency technology, applied in the field of cutting processing, can solve problems such as vibration and noise reduction, achieve the effects of reducing aerodynamic noise, improving stiffness, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

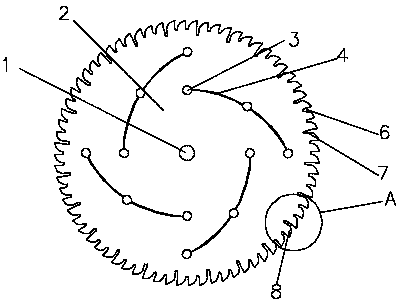

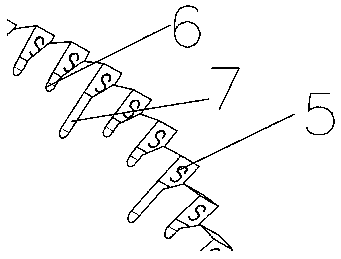

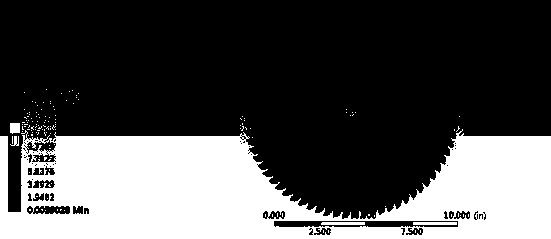

[0016] Below in conjunction with accompanying drawing, the technical scheme implemented in the present invention is described in detail, as Figure 1-2 As shown, the present invention provides a wear-resistant and high-efficiency sound-absorbing circular saw blade, a wear-resistant and high-efficiency sound-absorbing circular saw blade, including a saw blade base, the saw blade base includes a saw body base 2 and saw teeth 8, and the saw body base 2 is provided with The central hole 1 is characterized in that: the saw body base 2 is provided with a number of sound-absorbing grooves 3; the saw body base 2 is also provided with a number of sound-absorbing slits 4; between the adjacent saw teeth 8 are tooth grooves, and the The tooth grooves include shallow tooth grooves 6 and deep tooth grooves 7 ; grooves 5 are arranged on the serrations 8 .

[0017] Preferably, the sound-absorbing grooves 3 are circular, and the sound-absorbing grooves 3 are connected by sound-absorbing slits ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com