Automatic thickness measuring device

A thickness measurement, automatic technology, applied in mechanical thickness measurement and other directions, can solve problems such as poor measurement results, complex products, inconvenient repairs, etc., to avoid the phenomenon of unqualified components, reasonable and practical design, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

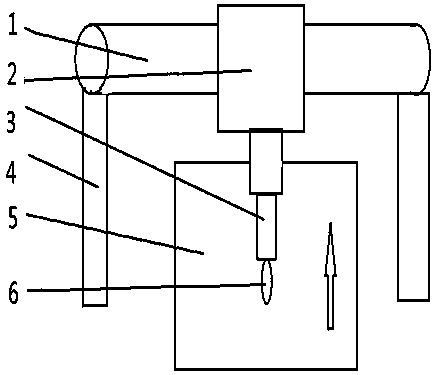

[0009] The display 2 can move left and right on the guide roller 1, the support 4 holds up and supports the whole device, the component 5 moves forward to drive the thickness measuring wheel 6 to rotate, and the height of the thickness measuring wheel 6 makes the telescopic rod 3 stretch up and down, causing the The numerical value changes, and the thickness change of the component 5 is finally observed. In the continuous production process, the part 5 is automatically transferred forward with the equipment, and the thickness measuring wheel 6 immediately follows the rotation of the part 5. The elastic force of the telescopic rod 3 makes the thickness measuring wheel 6 closely adhere to the part 5. The length displays a numerical value, so that the thickness of the component 5 is measured. The display 2 can move left and right on the guide roller 1, so that the thickness of each position can be measured conveniently.

[0010] During the one-year use by our company, every time...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap