Test pattern creation method, test pattern, printing apparatus, and storage medium

A technology for testing patterns and manufacturing methods, applied to printing devices, devices for permanent visual display, printing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

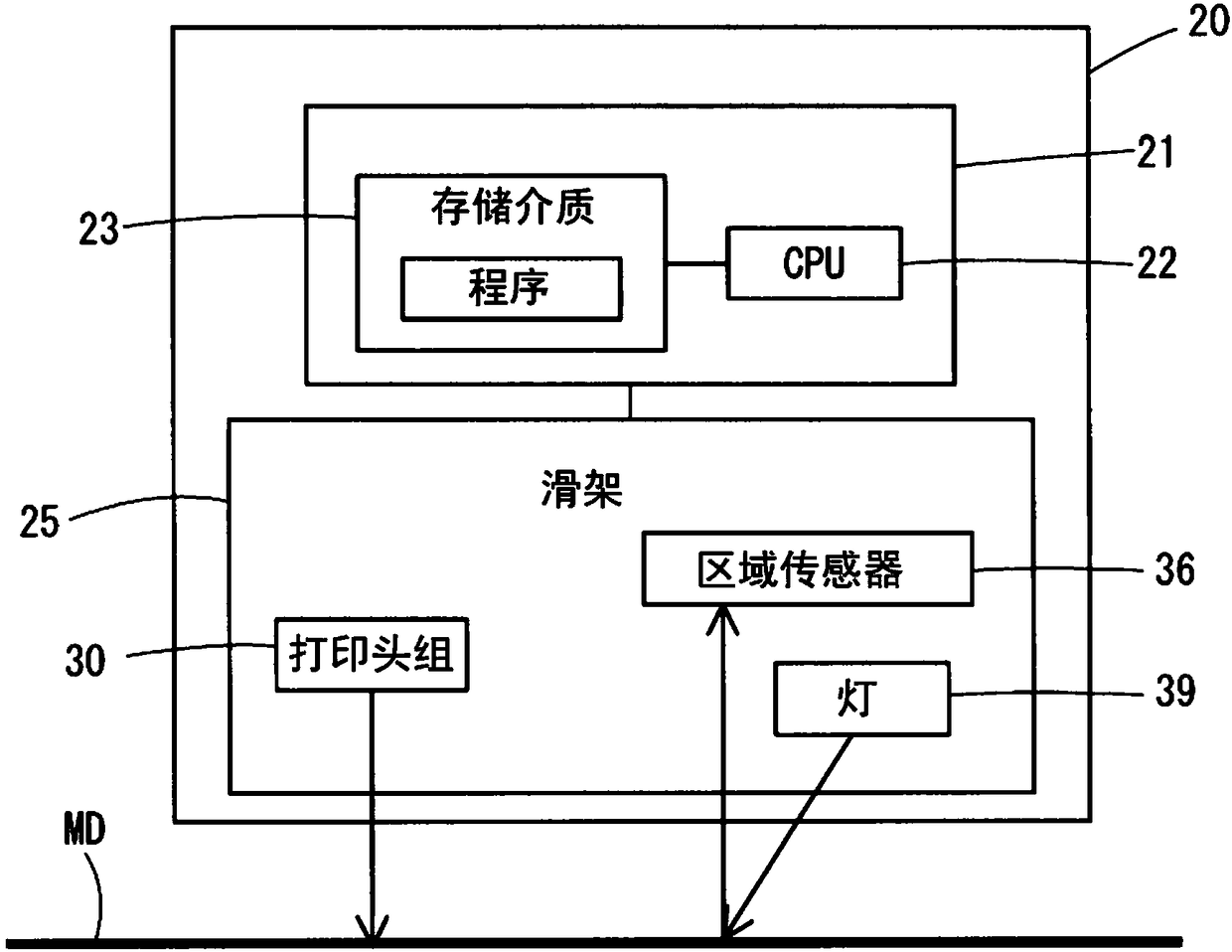

[0029] figure 1 is a functional block diagram of the printing device 20 . The printing device 20 includes a control unit 21 and a carriage 25 . The control unit 21 includes a CPU (Central Processing Unit, central processing unit) 22 and a storage medium 23 . The carriage 25 includes a head group 30 , an area sensor 36 and a lamp 39 .

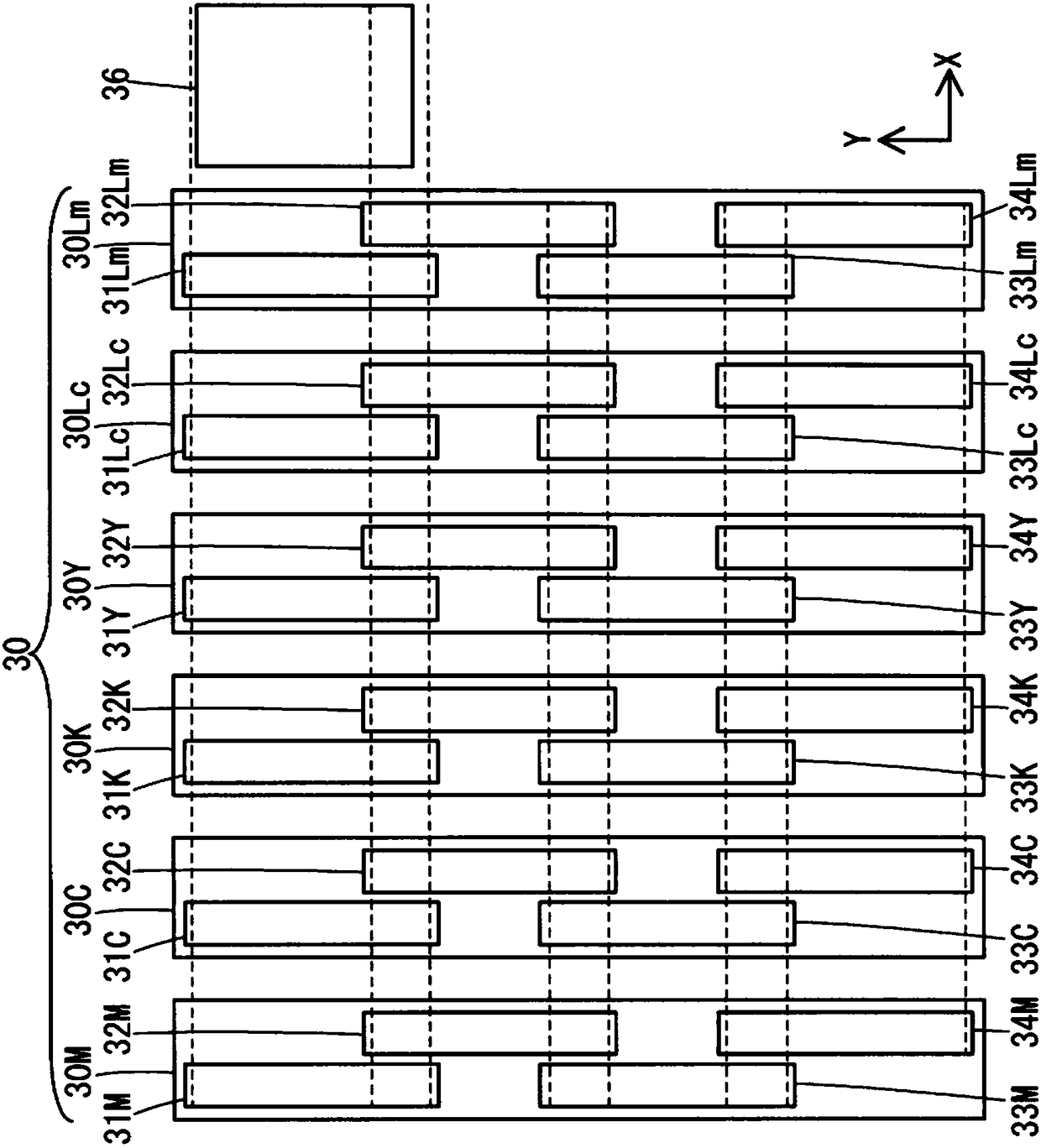

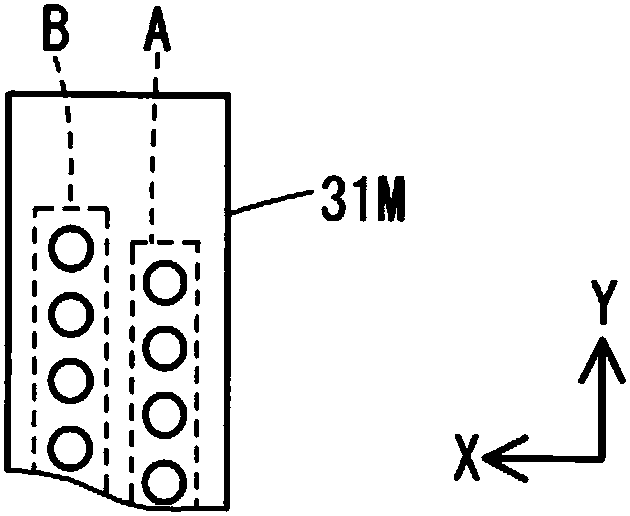

[0030] The printing device 20 forms dots on the printing medium MD by ejecting ink onto the printing medium MD. The printing device 20 ejects six colors of ink. The 6 colors refer to CMYKLcLm, that is, cyan, magenta, yellow, black, light cyan, and light magenta. In order to form dots, the printing device 20 scans the carriage 25 in the main scanning direction and conveys the printing medium MD in the sub scanning direction. The main scanning direction intersects with the sub-scanning direction, more specifically, is orthogonal to the sub-scanning direction.

[0031] The area sensor 36 measures the brightness value on the printing medium MD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com