Punching die mechanism

A die and support plate technology, applied in the die processing field, can solve the problems of die wear, frequent replacement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

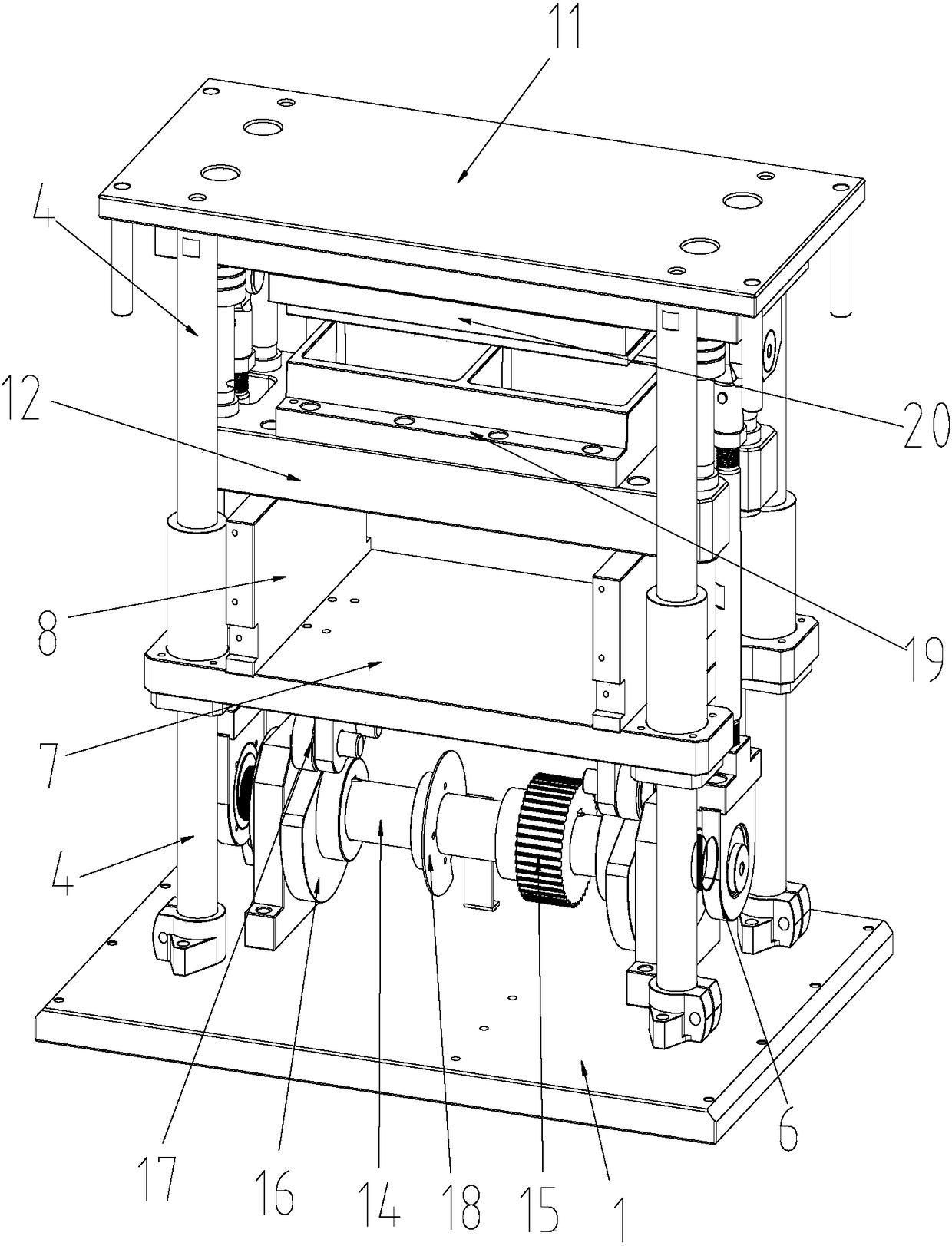

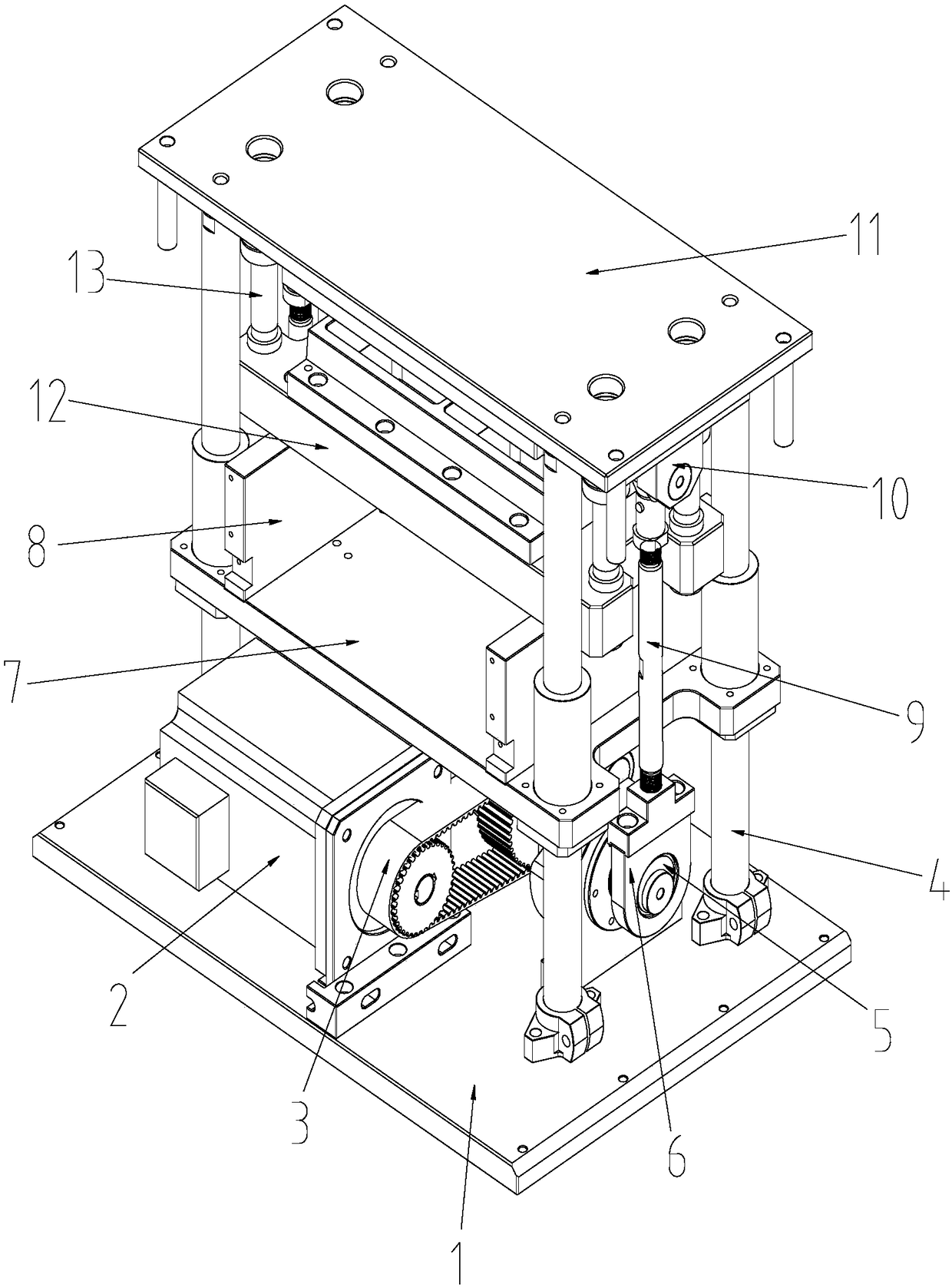

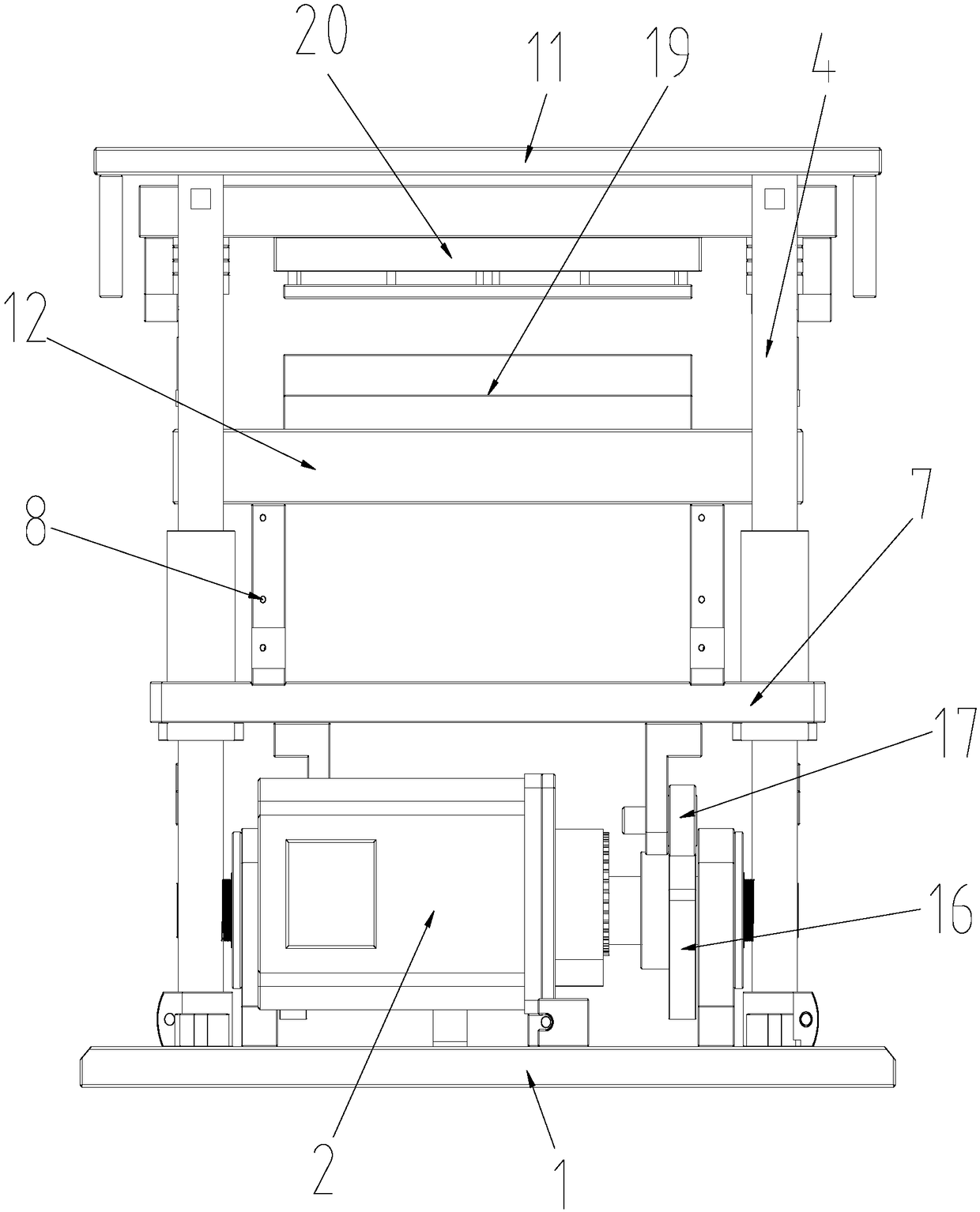

[0021] See attached Figure 1 to Figure 4 As shown, a die mechanism in this embodiment includes a mechanism bottom plate 1 and a mechanism top plate 11 distributed up and down, and a long guide column 4 is arranged between the mechanism top plate 11 and the mechanism bottom plate 1. The number of the above-mentioned long guide columns 4 There are four, distributed at the four corners of the mechanism bottom plate 1 and the mechanism top plate 11 (in this embodiment, the mechanism bottom plate 1 and the mechanism top plate 11 are both square structures). The long guide post 4 is provided with a guide post cover A, and the guide post cover A is connected to the die support base plate 7, and the die support base plate 7 is located between the mechanism base plate 1 and the mechanism top plate 11. The lower end surface of the mechanism top plate 11 is provided with contour columns, and the above-mentioned contour columns are arranged at four corners of the mechanism top plate 11 ....

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap