A high-precision high-speed punch

A high-speed punching and high-precision technology, applied in the field of machine tools, can solve problems such as large fluctuations in product size, unstable air pressure, and small punching force range, and achieve the effects of improving product processing efficiency, automation, and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

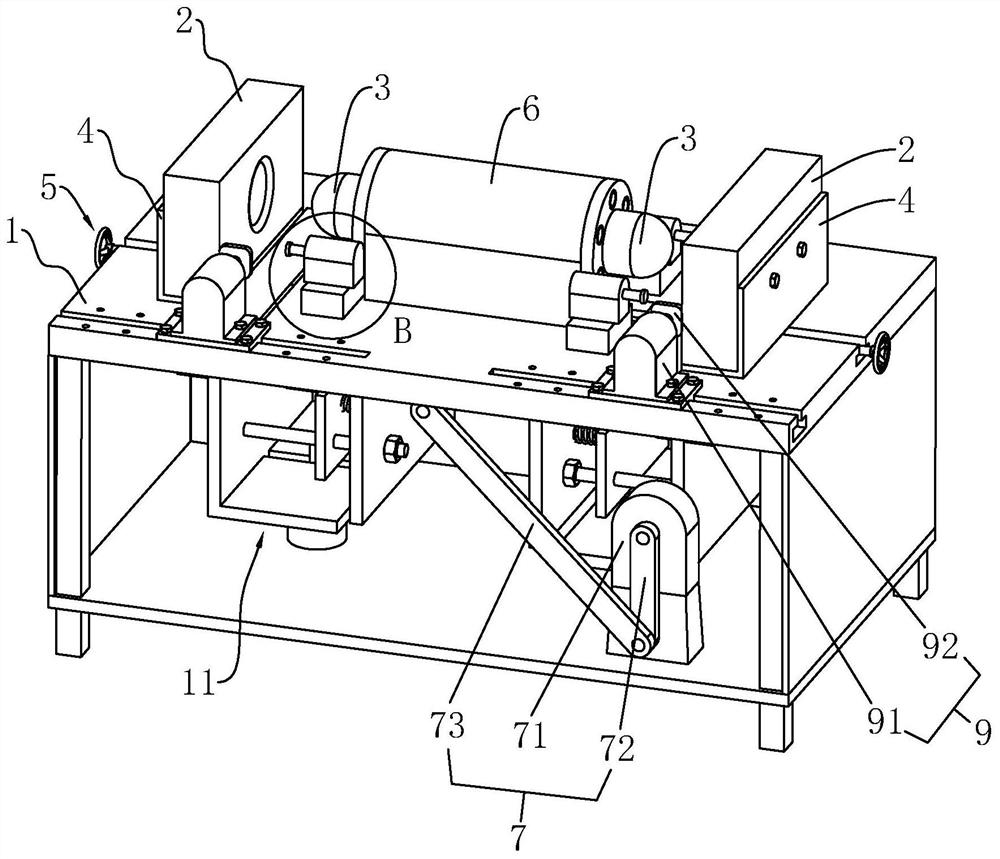

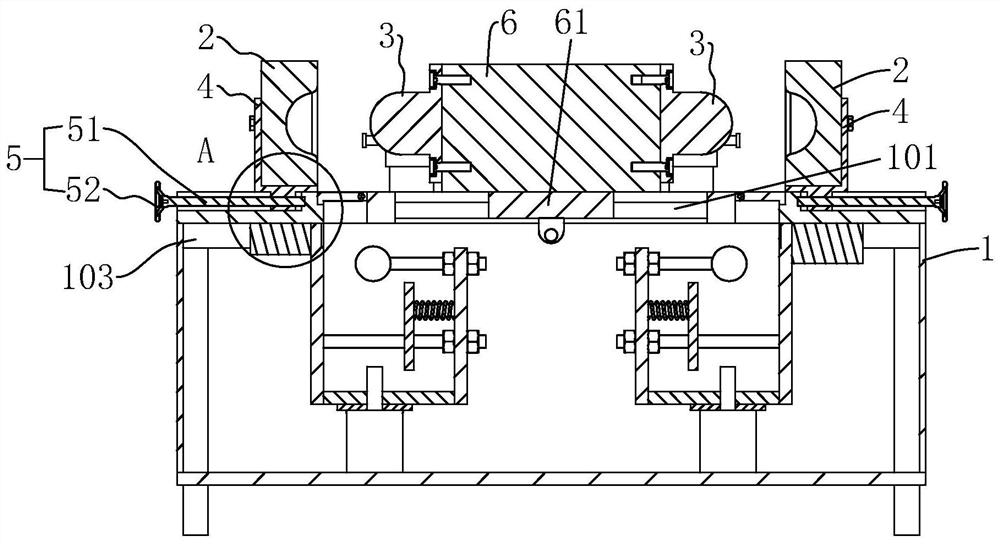

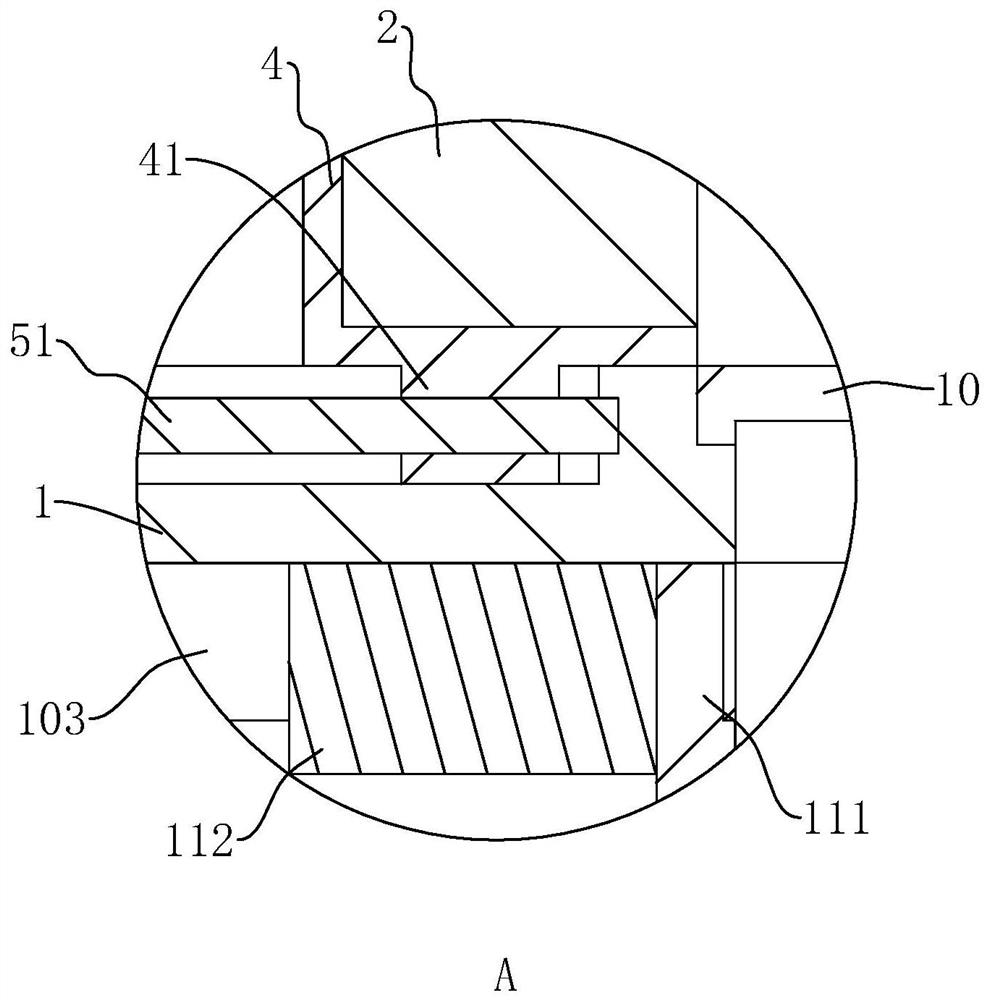

[0041] See figure 1 A high-precision high-speed punch, including a table 1, a stamped concave die 2 fixed to the table 1 and a sliding shift disposed on the table 1, and a table 1 is also provided with a driving stamping The convex mold 3 is a drive mechanism 7 that linearly reciprocates. In the actual work, the workpiece is placed at the stamping die 2, the drive mechanism 7 drives the punching convex mold 3 away from or near the stamped concave die 2; during this process, the punching convex mold 3 impacts the workpiece, thereby completing the workpiece together with the stamped die 2 Stamping.

[0042] See figure 1 The above stamping fixtures 2 are symmetrically disposed in the working table 1 longitudinal direction. In order to install the two stamping recess 2, two sets of fixed seats 4 for fixing the two stamping die 2 are provided on the table 1, and the two stamped concave die 2 can be disassembled to the corresponding fixing seat 4, respectively, respectively. One side of...

Embodiment 2

[0057] See Figure 7 A high-precision high speed punch, which is different from that of Example 1, and the two stamped concave molds 2 are first stamped concave die 21 and the second stamping die 22, and the first stamped die 21 and the second.The stamping die 22 corresponds to two different stamped structures, that is, the mold forming side structure of the two is not the same.Correspondingly, the two stamping convex molds 3 are respectively used for the first stamping convex mold 31, respectively, and the first stamped convex mold 31 and the second stamping convex mold 32 are respectively used to cooperate with the first stamping die 21 and the first.Two stamping die 22.As such, the punch can be completed simultaneously to complete two forms of stamping, which helps further improve processing efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap