Continuous die mechanism without connecting materials for hard disk top cover

A technology of mold mechanism and top cover, which is applied in the field of plastic stamping and forming, and can solve problems such as inconvenient continuous punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

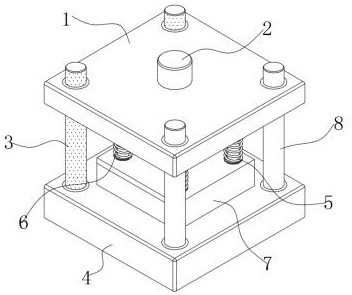

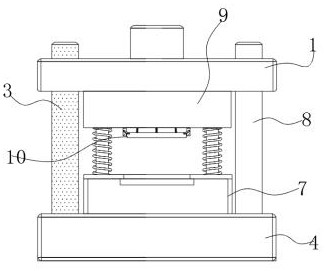

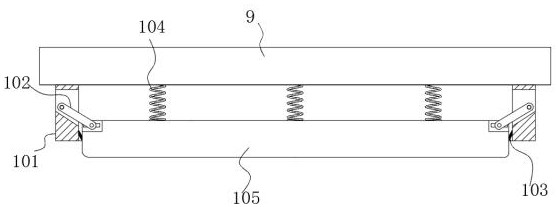

[0025] see Figure 1~7 , in an embodiment of the present invention, a non-continuous mold mechanism for a hard disk top cover, which includes a connecting plate 1, a mold handle 2, a lower mold base 4 and an upper mold base 9, wherein the lower mold base 4 is A die 7 is fixed, and a punch assembly 10 is fixed on the lower surface of the upper die holder 9;

[0026] Two sets of loading column assemblies 3 and two sets of guide columns 8 are fixed at the four corners of the lower mold base 4, and two sets of loading column assemblies 3 and two sets of guide columns 8 are arranged symmetrically with respect to the incoming material direction respectively, Wherein, the guide column 8 is slidingly connected with the connecting plate 1, and the driving end of the feeding column assembly 3 is fixedly connected with the connecting plate 1, so that the feeding end of the feeding column assembly 3 is driven to carry out the process through the upward movement of the connecting plate 1. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap