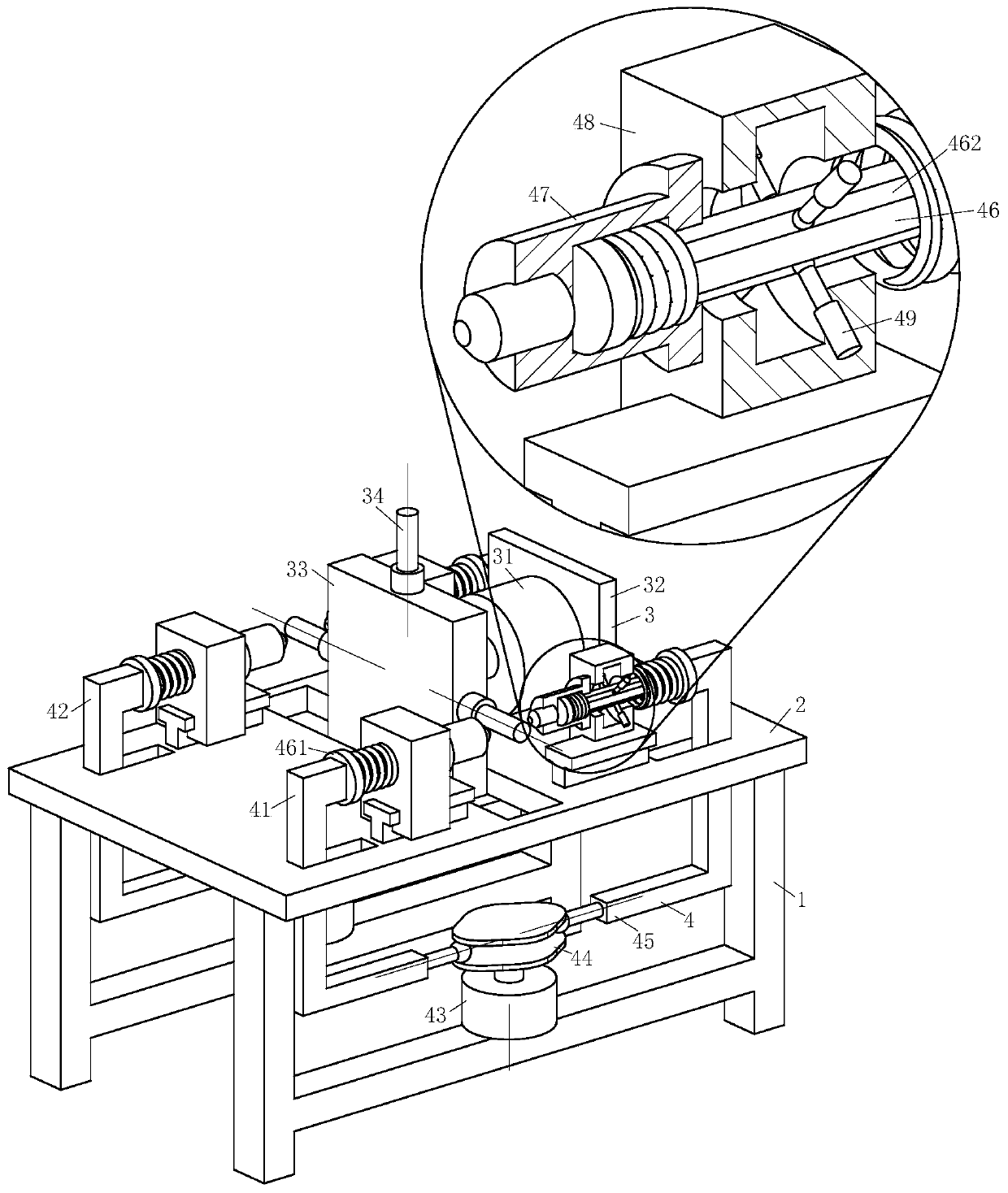

A hedge type multi-station hydraulic press

A hydraulic punching and multi-station technology, applied in the field of punching machines, can solve the problems affecting punching accuracy, bending of punching rods, offset of punching position, etc., to avoid deformation of punching rods, improve punching efficiency, and reduce impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

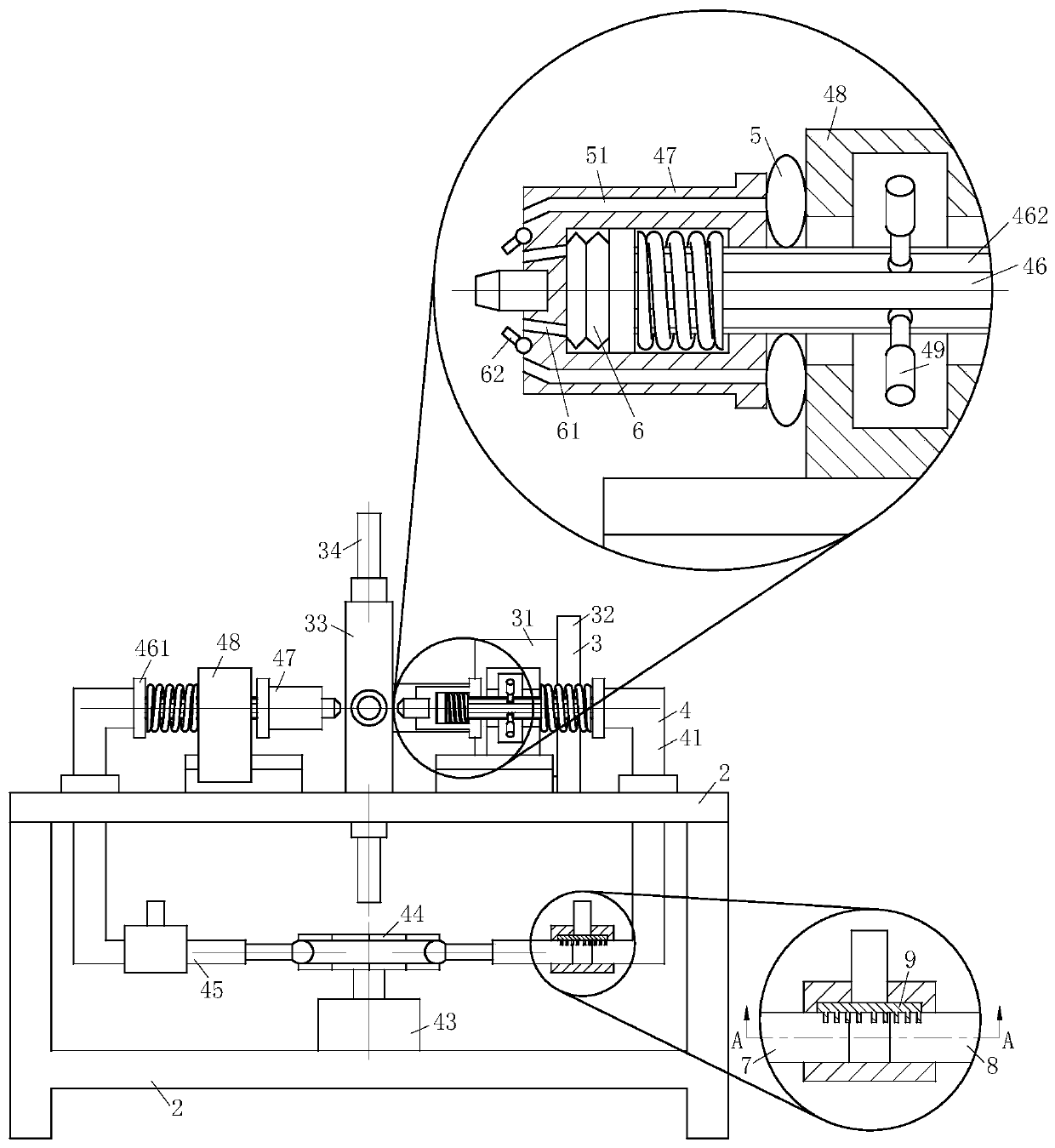

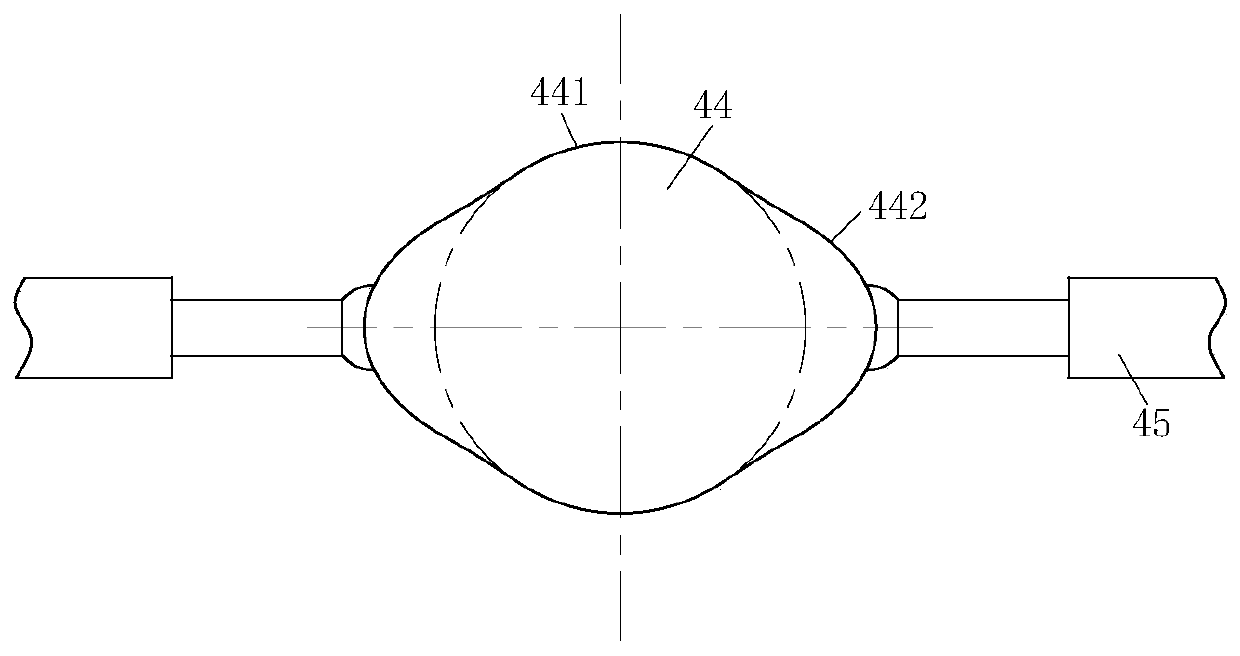

[0033] As an embodiment of the present invention, the connecting rod 45 includes a No. 1 rod 7 and a No. 2 rod 8; one end of the No. 1 rod 7 is connected with a cam 44; the other end of the No. 1 rod 7 is provided with a spiral groove, One end of the No. 2 rod 8 corresponding to the No. 1 rod 7 is provided with a spiral groove, and the other end of the No. 2 rod 8 is connected with a punch 46; The rotation is used to adjust the distance between the No. 1 rod 7 and the No. 2 rod 8; the adjustment of the distance between the No. 1 rod 7 and the No. 2 rod 8 is used to adjust the punching depth.

[0034] During work, at first according to the requirement, fix punches of different specifications on the mounting seats 47 of No. 1 hedging unit 41 and No. 2 hedging unit 42, and No. 1 hedging unit 41 first punches the workpiece once; The rotation makes the workpiece transfer to the working position of No. 2 hedging unit 42. At this time, a new workpiece is installed on the fixed mold 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap