A hydraulic punching machine for porous industrial aluminum profiles

A technology for hydraulic punching and aluminum profiles, which is applied in the field of stamping machinery, can solve the problems of crushed shavings, difficult removal of powdery shavings, scrapped workpieces, etc., and achieves the effect of reducing adhesion and facilitating centralized processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

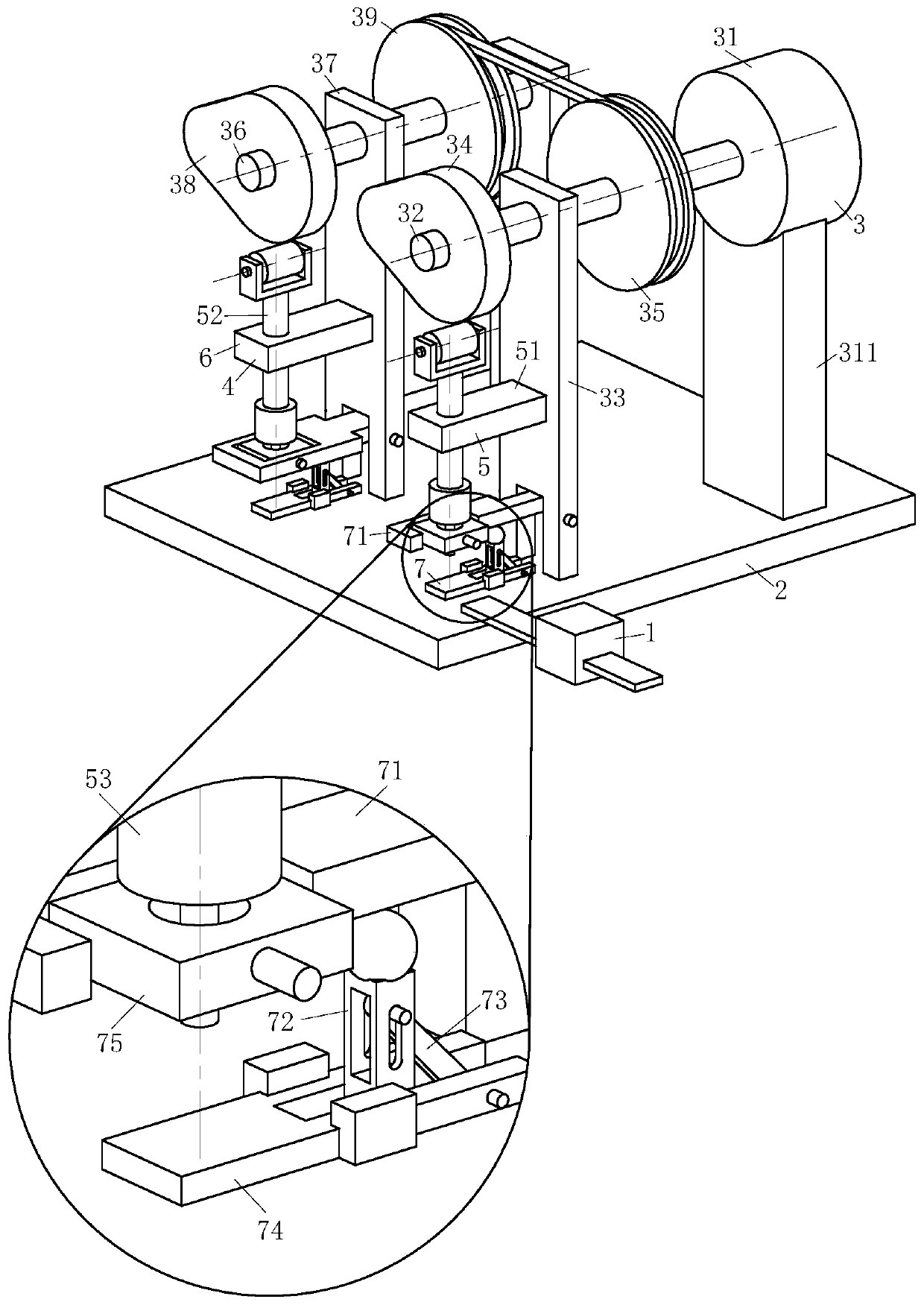

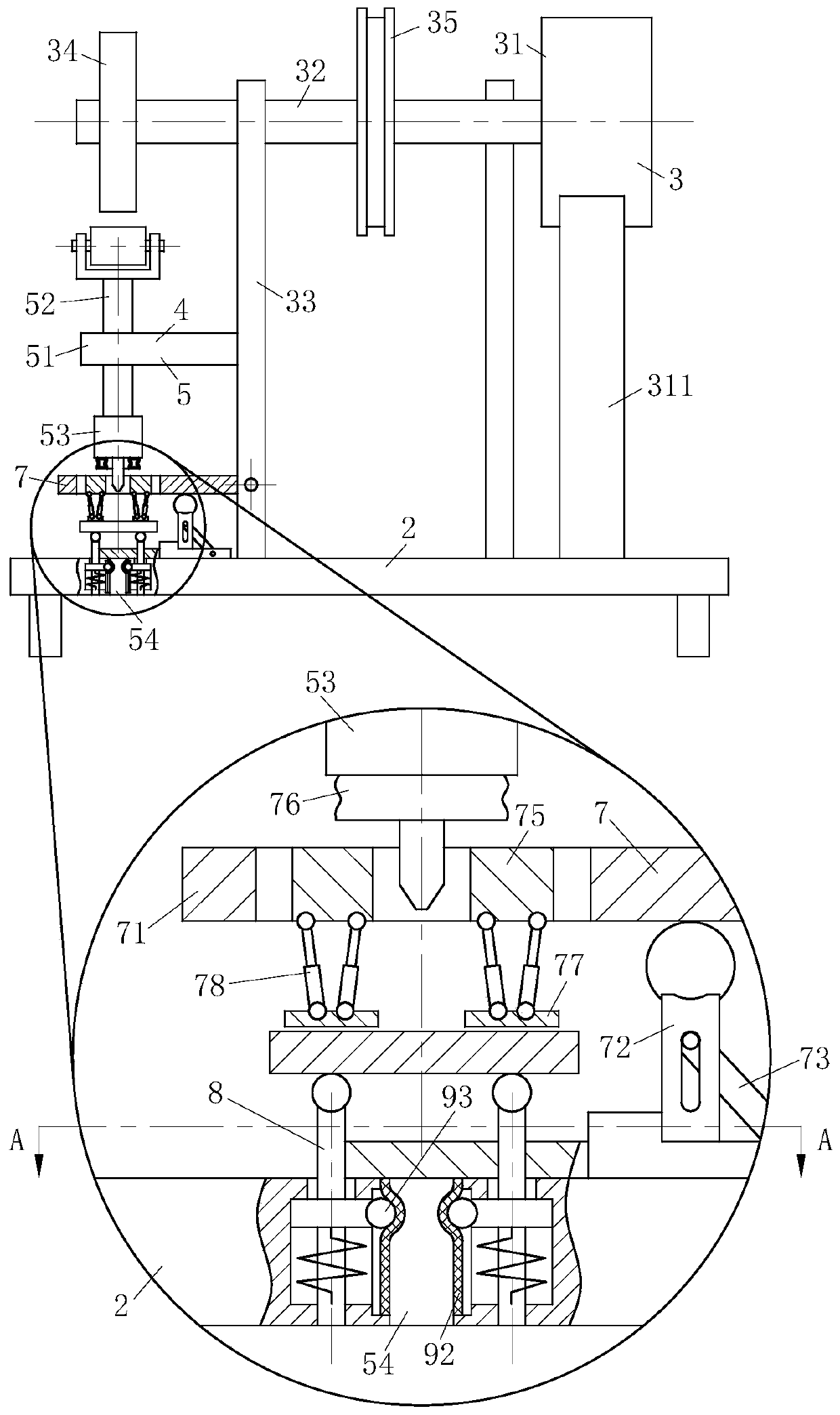

[0033] As an embodiment of the present invention, the middle part of the rotating plate 71 is rotatably mounted with a floating plate 75; one end of the round table 53 is provided with an annular air bag 76, and the annular air bag 76 is provided with a group of air holes facing the punch, and the floating plate 75 Squeezing the annular bladder 76 can generate air flow. Through the floating plate 75, the impact force of the round platform 53 is evenly distributed, avoiding the side bending of the punch rod 52, and an annular air bag 76 is provided at the same time, to reduce the impact force of the rotating shaft and remove powder dust attached to the punch.

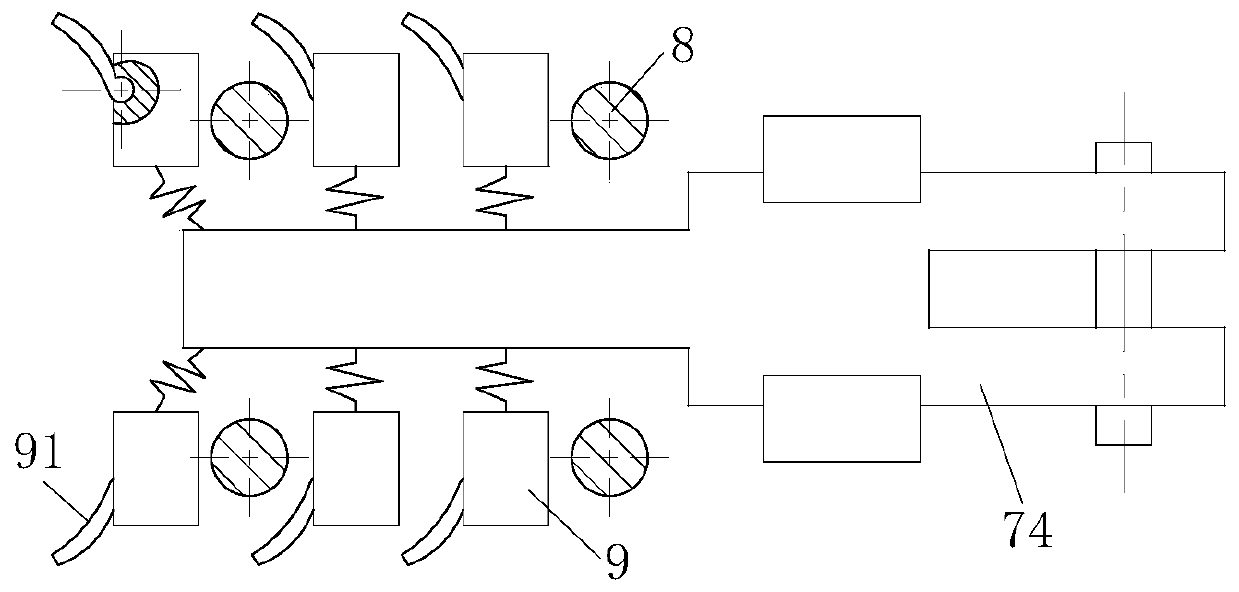

[0034] As an embodiment of the present invention, the bottom hole 54 is surrounded by a group of support rods 8 that are slidably installed on the bottom plate 2, and the top of the support rods 8 is provided with rolling balls, and the support rods 8 are used to support the workpiece. The floating plate 75 can press the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap