Laminated Shims for Disc Brakes

A technology of disc brakes and gaskets, applied in the direction of brake types, brake components, applications, etc., can solve problems such as brake pad vibration, uneven wear of lining, buzzing noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0081] [the first example of embodiment]

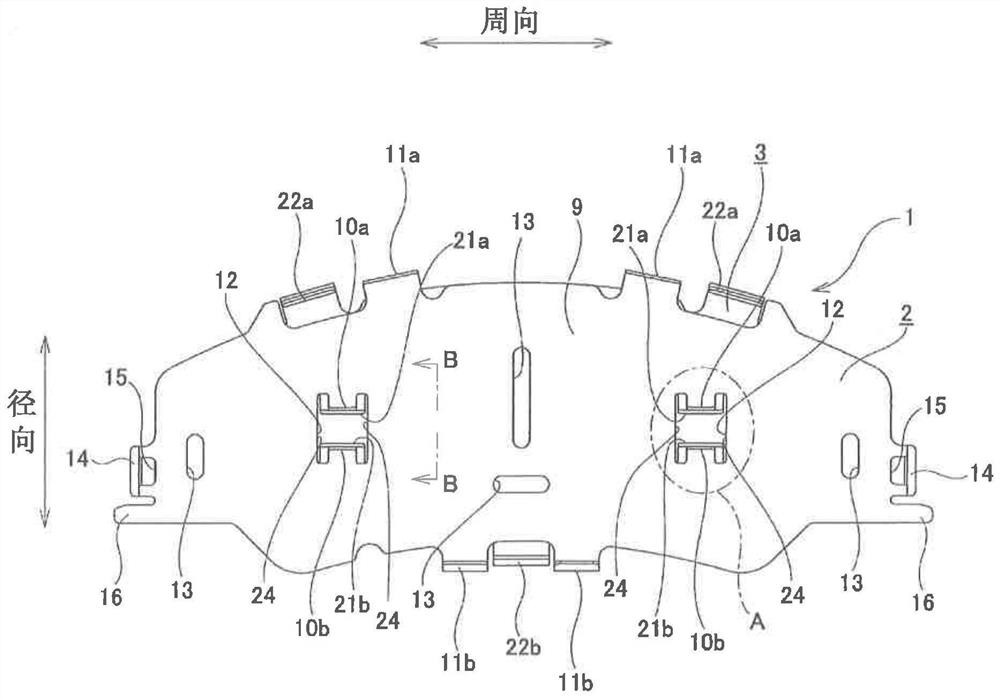

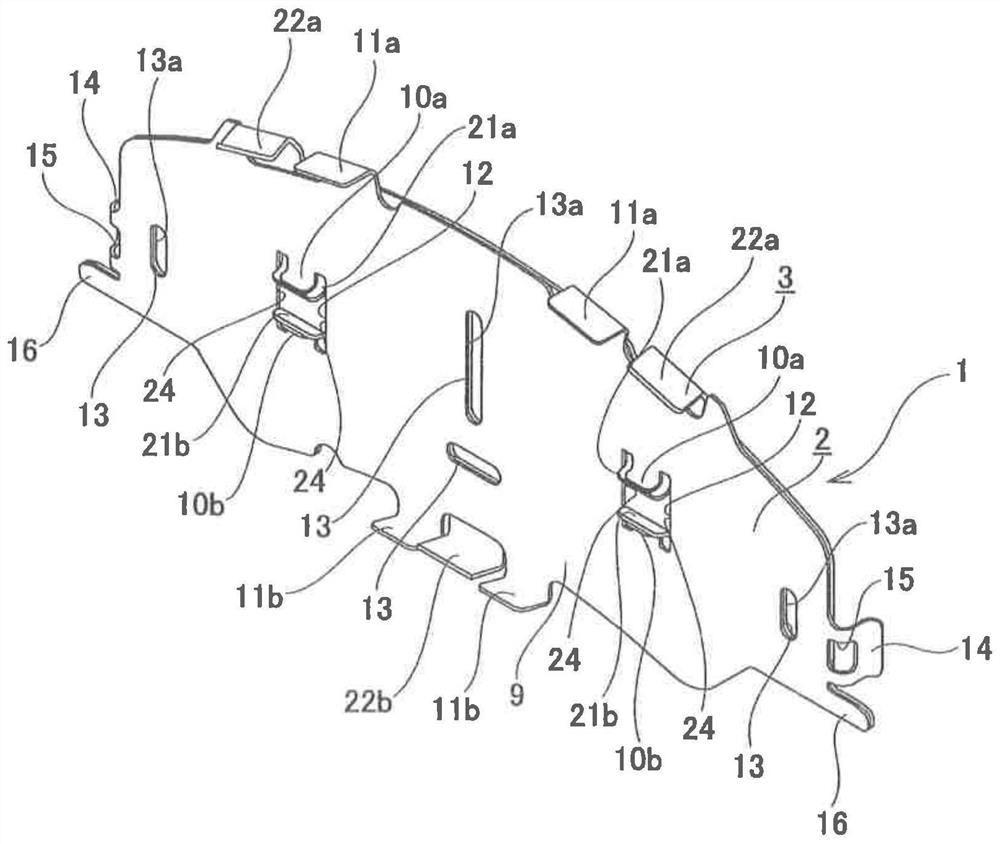

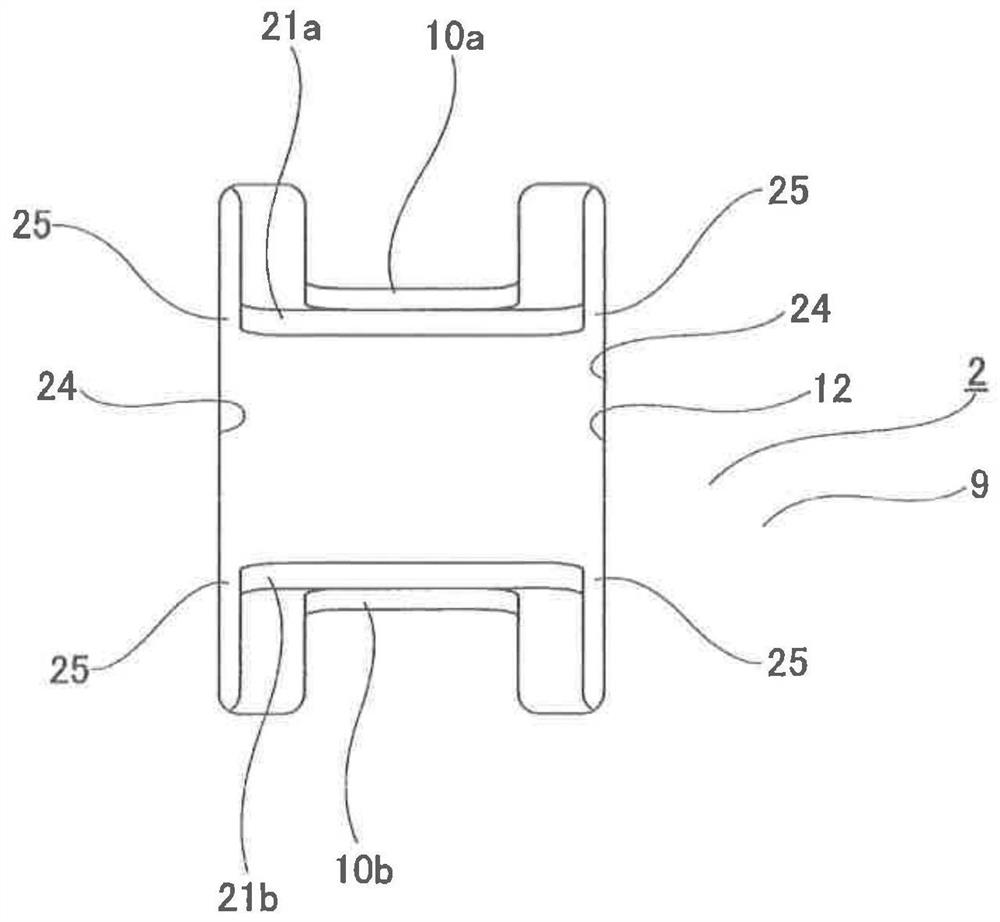

[0082] use Figure 1 to Figure 12 A first example of the embodiment will be described. The stacked gasket 1 of this example includes a base gasket plate 2 and a cover body gasket plate 3, such as Figure 9 ~ Figure 12 As shown, is loaded on the brake pad 4. The brake pad 4 is constructed by attaching a fixed lining 6 in front of the pressure plate 5 . In a state where such a brake pad 4 is incorporated into a disc brake device, the laminated spacer 1 is disposed between the back surface of the pressure plate 5 constituting the brake pad 4 and the pressing member 7 that presses the back surface of the pressure plate 5 . part. In addition, the front surface of the inner liner 6 constituting the brake pad 4 faces the axial side surface of the rotor 31 .

[0083] In the state before the laminated spacer 1 is mounted on the brake pad 4 in this example, the base spacer plate 2 and the cover body spacer plate 3 are bonded to each other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com