Micro-electrolytic wire-cutting processing method of wire electrode workpiece with different speed compound motion

A cutting and compound motion technology, applied in electric processing equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as increased mass transfer ability, poor, short-circuit processing, etc., to achieve improved efficiency and stability, electrical conductivity The effect of uniform distribution and improved mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

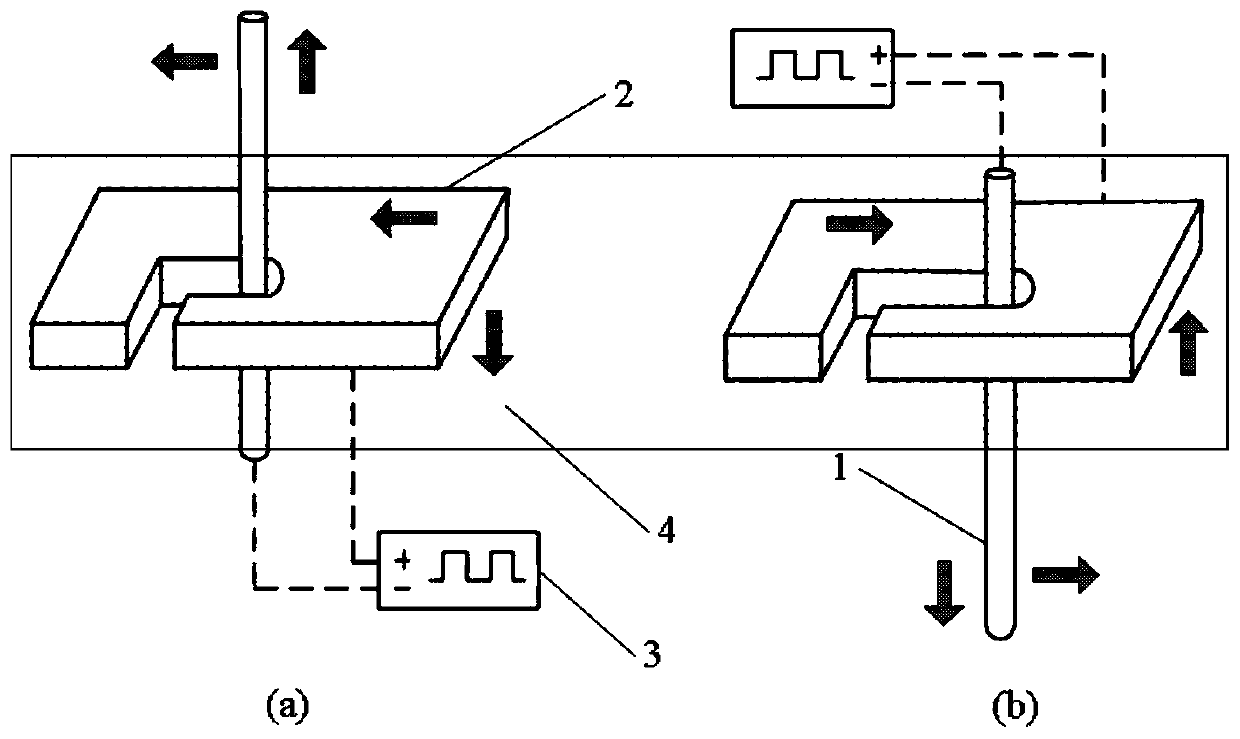

[0022] figure 1 In the schematic diagram of the fine electrolytic wire cutting machining method with different speed compound motion of the wire electrode workpiece, (a) is the different speed compound motion of the wire electrode relative to the workpiece, and (b) is the different speed compound motion of the workpiece relative to the wire electrode.

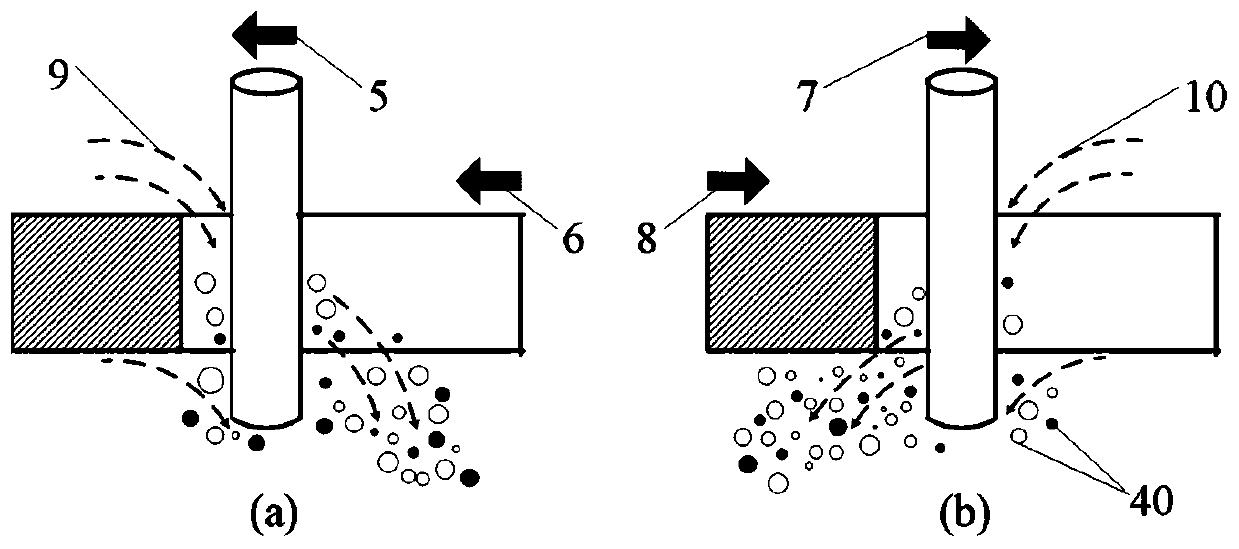

[0023] figure 2 In the X-Y feed cutting process and product discharge schematic diagram of the wire electrode workpiece shown, (a) is the different speed feed movement of the wire electrode relative to the workpiece, and (b) is the different speed feed movement of the workpiece relative to the wire electrode.

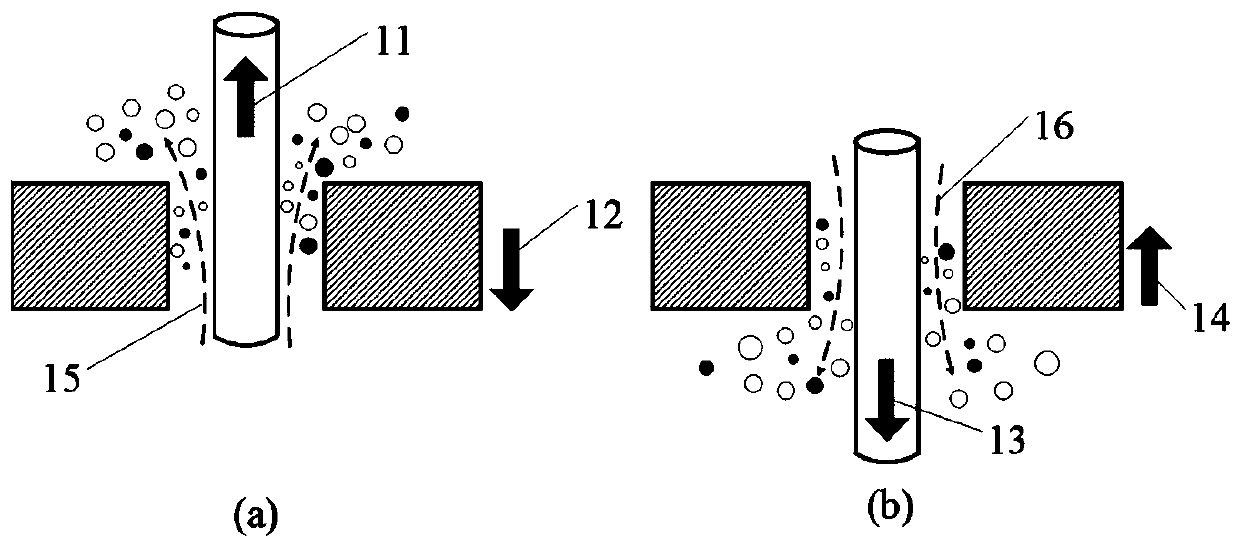

[0024] image 3 In the schematic diagram of Z-direction reciprocating motion and product discharge of the wire electrode workpiece shown, (a) is the relative motion of the wire electrode and the workpiece, and (b) is the opposite motion of the wire electrode workpiece.

[0025] Figure 4 The schematic diagram of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com