Single Hall sensor based calibration method for solar panel rotation accuracy

A technology of Hall sensor and calibration method, which is applied to instruments, measuring devices, electrical devices, etc., can solve the problems of high cost and no consideration of sensor detection errors, and achieves low cost, accurate correction of on-orbit rotation errors, and hardware structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

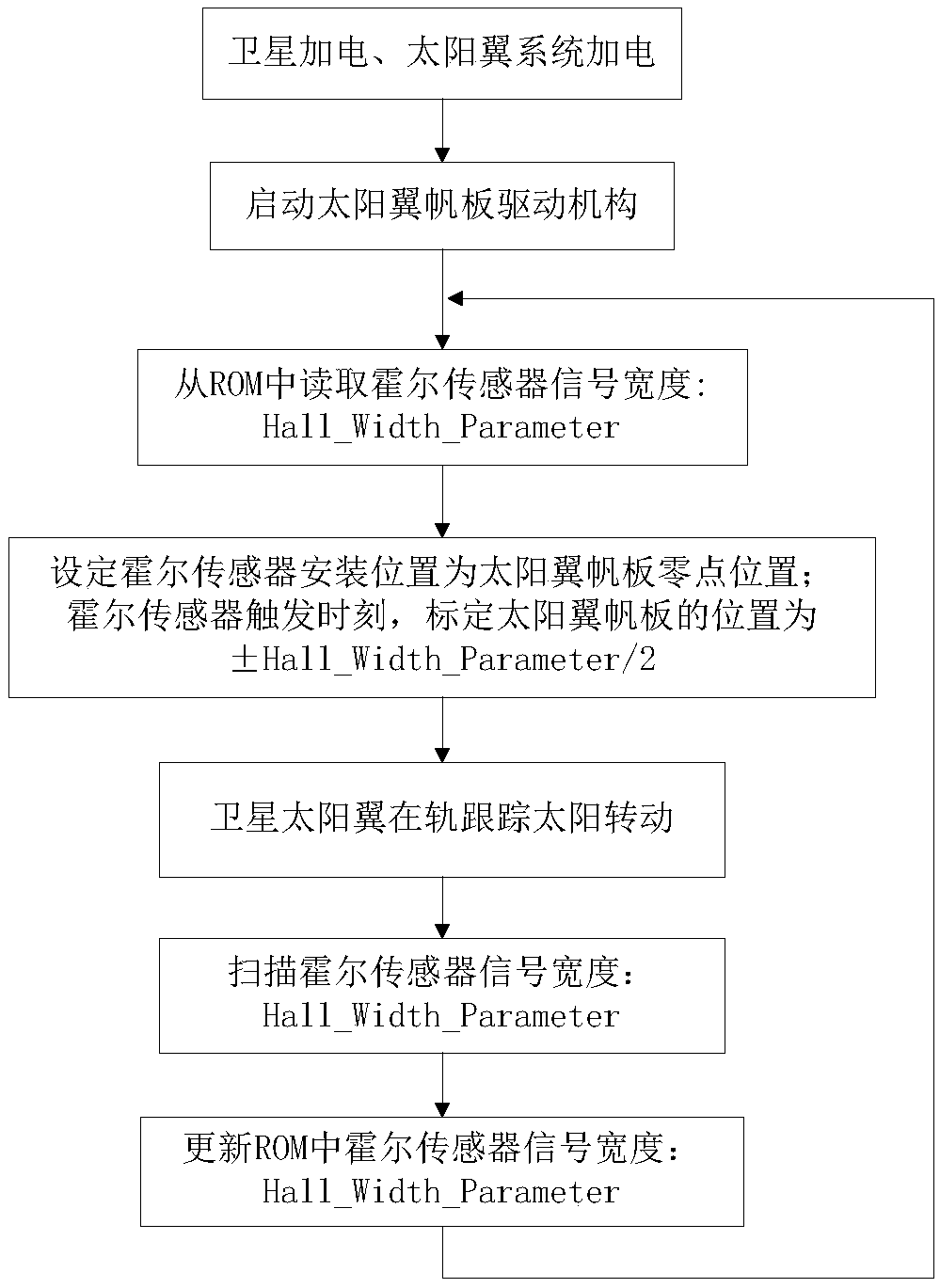

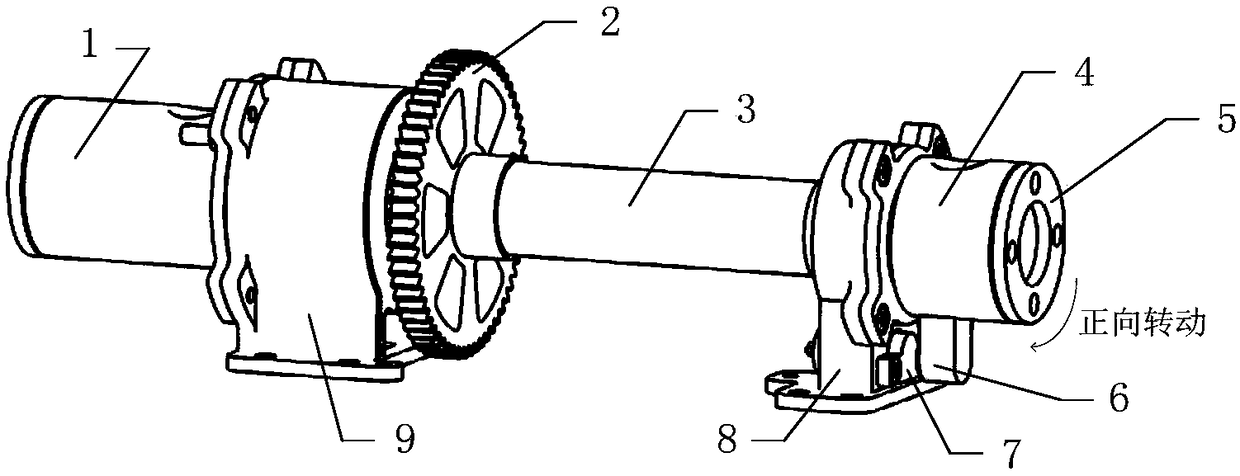

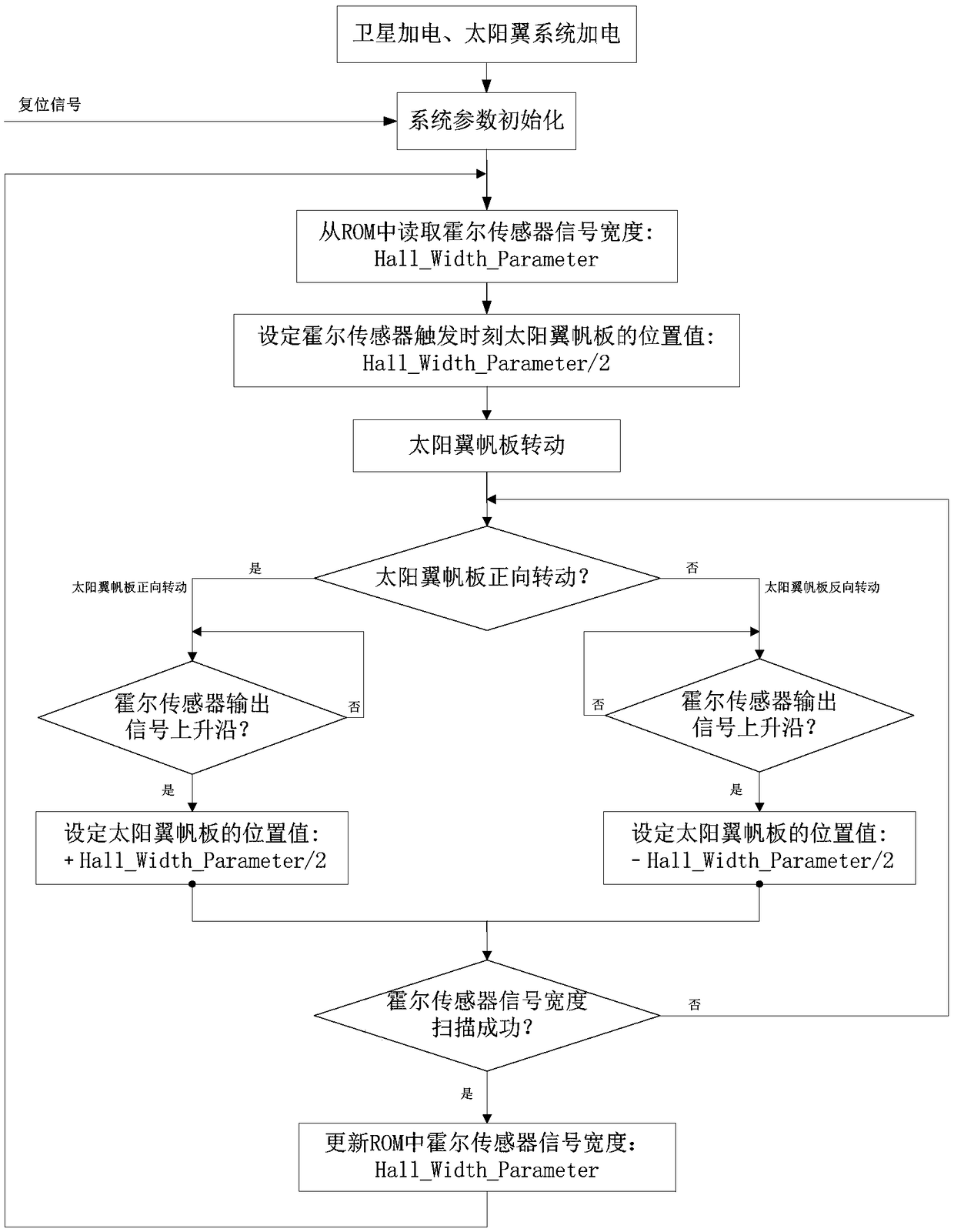

[0036] Please refer to the attached Figure 2 ~ Figure 4 , to illustrate the specific mode of the present invention.

[0037] Specifically, the Hall sensor 7 outputs a Hall sensor signal according to the magnetic field strength of the magnet 6. When the magnet 6 is far away from the Hall sensor 7, the Hall sensor 7 outputs a high-level signal 10 or 15; When the Hall sensor is 7, the Hall sensor outputs a low level signal 13.

[0038] Specifically, when the Hall sensor 7 is rotating in the forward direction and the Hall sensor outputs a signal rising edge (that is, the signal jump edge 14), the value of the rotation position of the calibrated solar wing sail is +Hall_Width_Parameter / 2; when the Hall sensor 7 reverses At the moment when the direction is rotating and the hall sensor output signal rises (that is, the signal transition edge 11), the value of the calibrated solar wing sailing position is -Hall_Width_Parameter / 2.

[0039]Specifically, the solar wing sail is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com