A method and device for measuring the density of a composite grouted rockfill dam based on additional mass

A technology of density measurement and additional mass, which is applied in the field of engineering geophysical exploration, can solve the problems of not showing the linear relationship of rockfill bodies, limiting the application range of the additional mass method, and large variation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples are intended to illustrate the present invention, but not to limit the scope of the present invention.

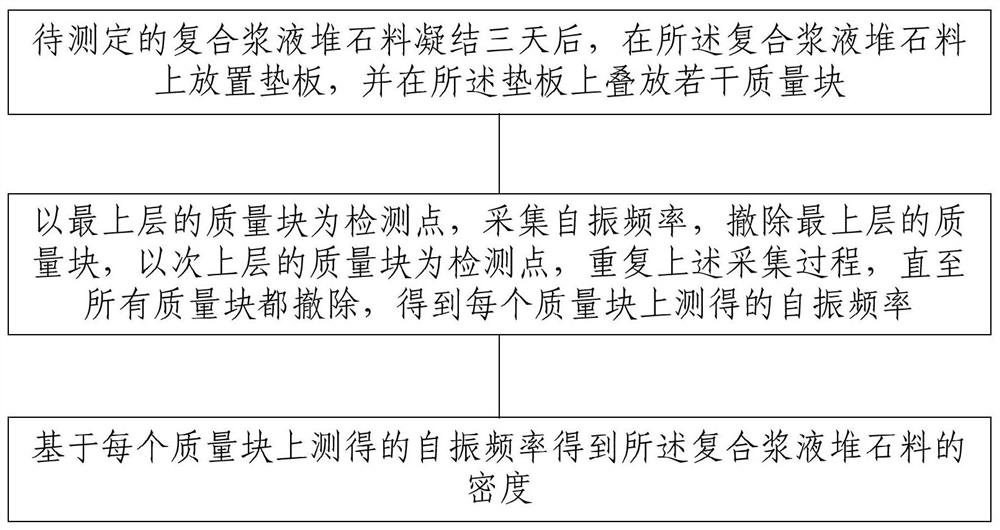

[0032] like figure 1 As shown, the figure shows a method for measuring the density of a composite slurry rockfill dam, including:

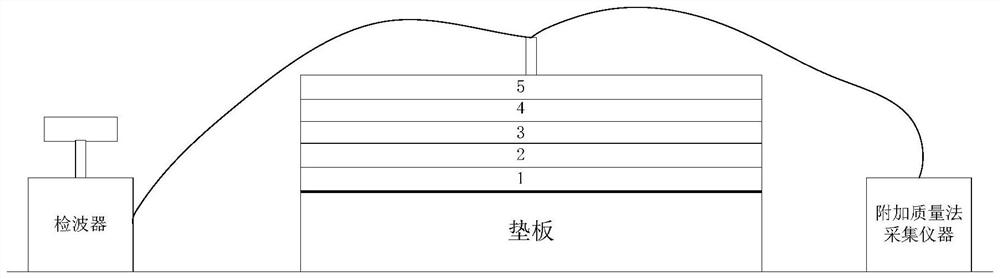

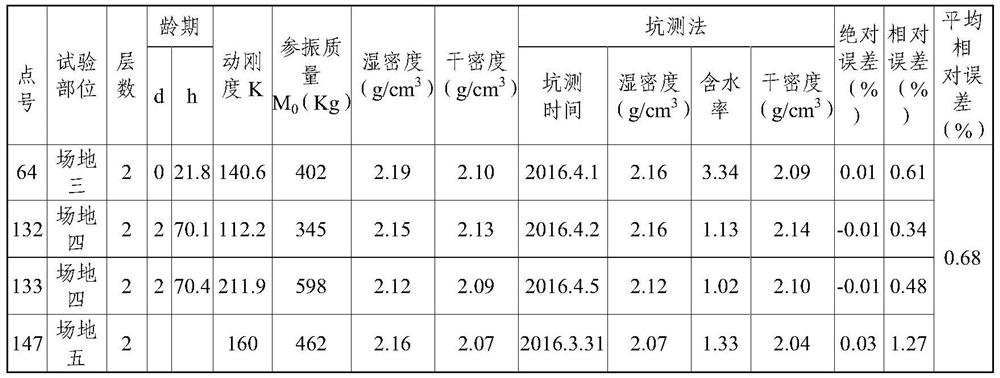

[0033] After the composite grout rockfill material to be determined is condensed, a backing plate is placed on the composite grout rockfill material, and several mass blocks are stacked on the backing plate; detection. The parameters dynamic stiffness K and paravibration mass M are tested by the additional mass method of several non-coincident measuring points on the rolling surface 0 Mathematical statistics were performed at the time points where the range of change was less than 3%, and the best on-site test time (3 days) was analyzed.

[0034] In general, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com