Carton packaging adhesive tape automatic flattening mechanism and method

A tape, automatic technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high cost, inapplicability, inability to smooth the tape, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

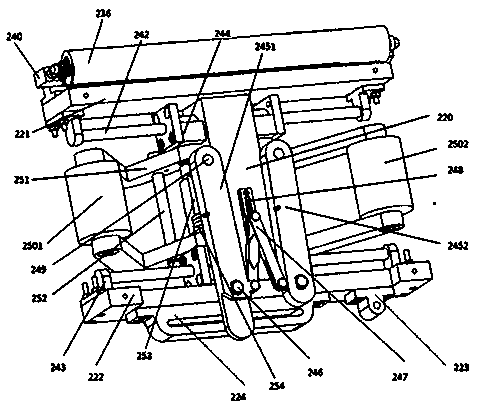

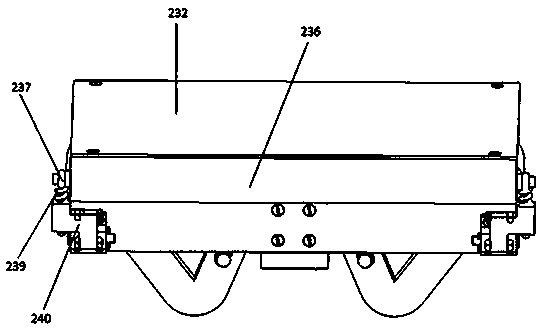

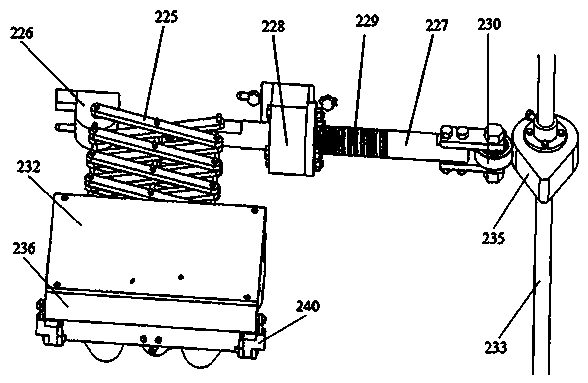

[0023] like figure 1 , figure 2 and image 3 As shown, the carton tape automatic smoothing mechanism includes a body fixing assembly, a front smoothing assembly, a smoothing push assembly, a slide rail assembly, a slide rail push assembly and a left and right smooth assembly. Wherein, the body fixing assembly includes a horizontal supporting column 220 , a front supporting body 221 , a rear supporting body 222 , a scissors fixing part 223 and a scissors sliding part 224 . The slide rail assembly includes a slide rail 242 , a slide rail fixing base 243 and a square slide table 244 . The slide rail assembly is installed on the body fixing assembly. A horizontal support column 220 is fixed between the front support body 221 and the rear support body 222. The horizontal support column body 220, the front support body 221 and the rear support body 222 form an I-shaped structure. Both the scissors fixing part 223 and the scissors sliding part 224 are fixed on the rear support bo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap