Column thermostat for gas chromatograph and gas chromatograph using it

A technology of gas chromatography device and gas chromatograph, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., and can solve problems such as contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

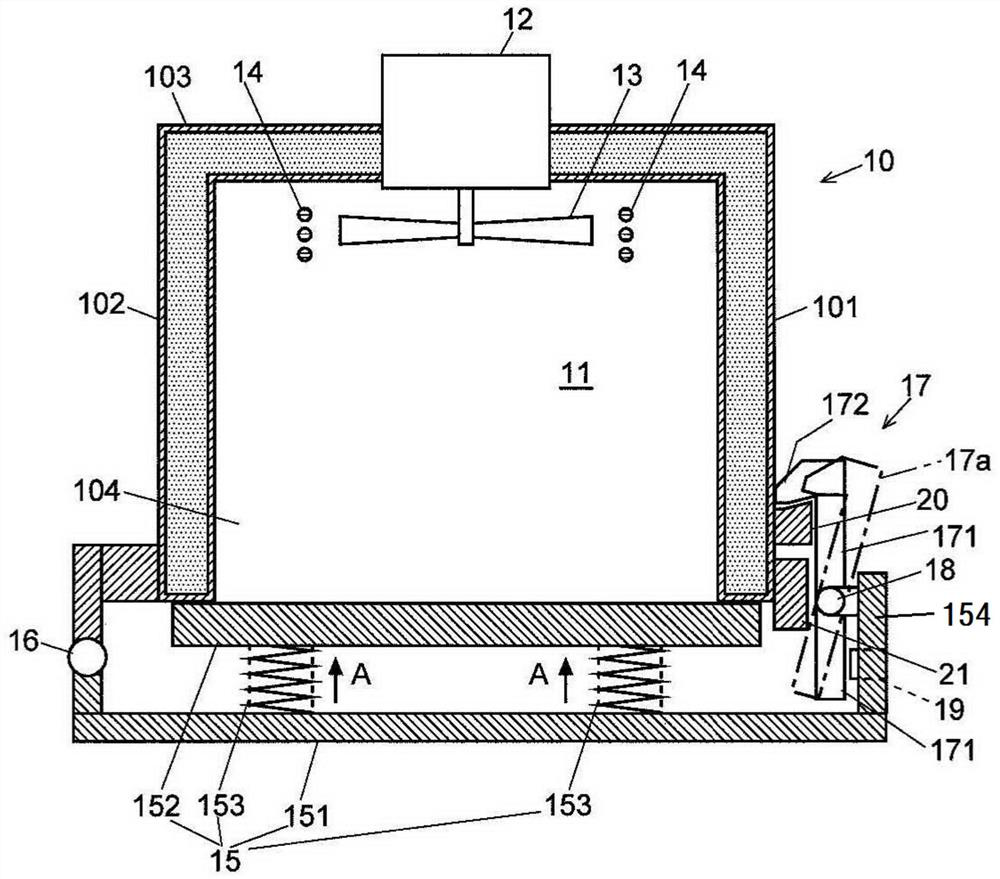

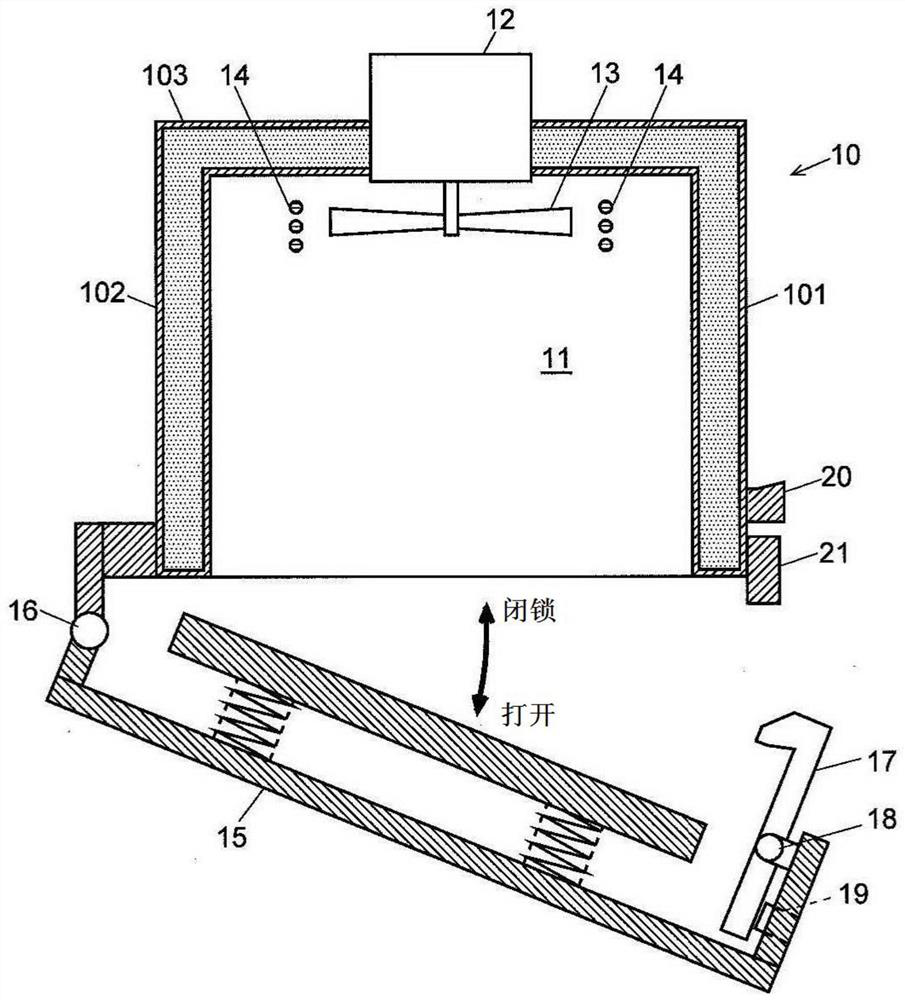

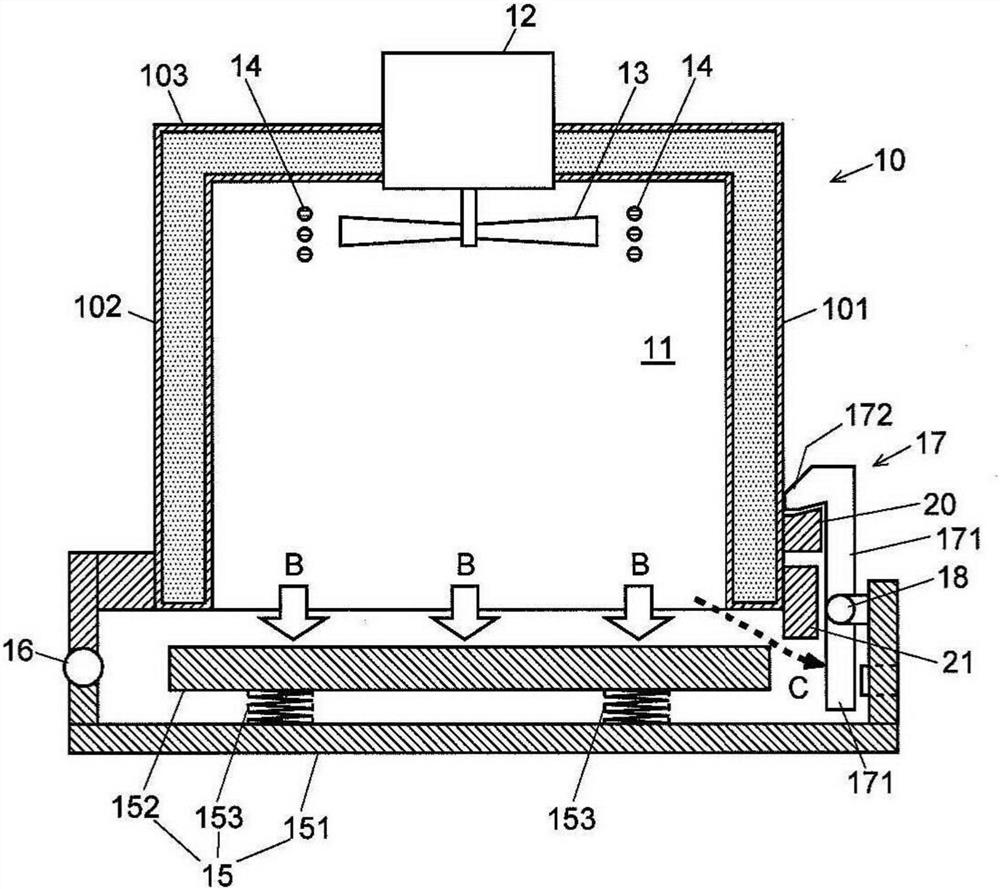

[0041] Next, an example of a column oven for a gas chromatograph and a gas chromatograph using the same according to the present invention will be described with reference to the drawings.

[0042] figure 1 It is a schematic horizontal cross-sectional view of the gas chromatograph column thermostat of this embodiment with the door locked, figure 2 It is a schematic horizontal cross-sectional view in a state where the door is opened in the gas chromatograph oven of this embodiment, image 3 It is a roughly horizontal cross-sectional view showing a state immediately after an explosion occurs in the inner space of the gas chromatograph column oven of this embodiment. pair and reference Figure 5 In the conventional gas chromatograph described above, the same components as the column thermostat are denoted by the same symbols.

[0043] In the column oven of this embodiment, the configurations of the column oven chamber main body 10 and the door 15 are completely the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com