Method for controlling turn-off phase delay time of brushless DC motor

A brushed DC motor and delay time technology, applied in the direction of torque ripple control, can solve the problems of commutation torque fluctuation, limit the application range of the motor, motor jitter, etc., and achieve the effect of weakening the high-speed commutation torque ripple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

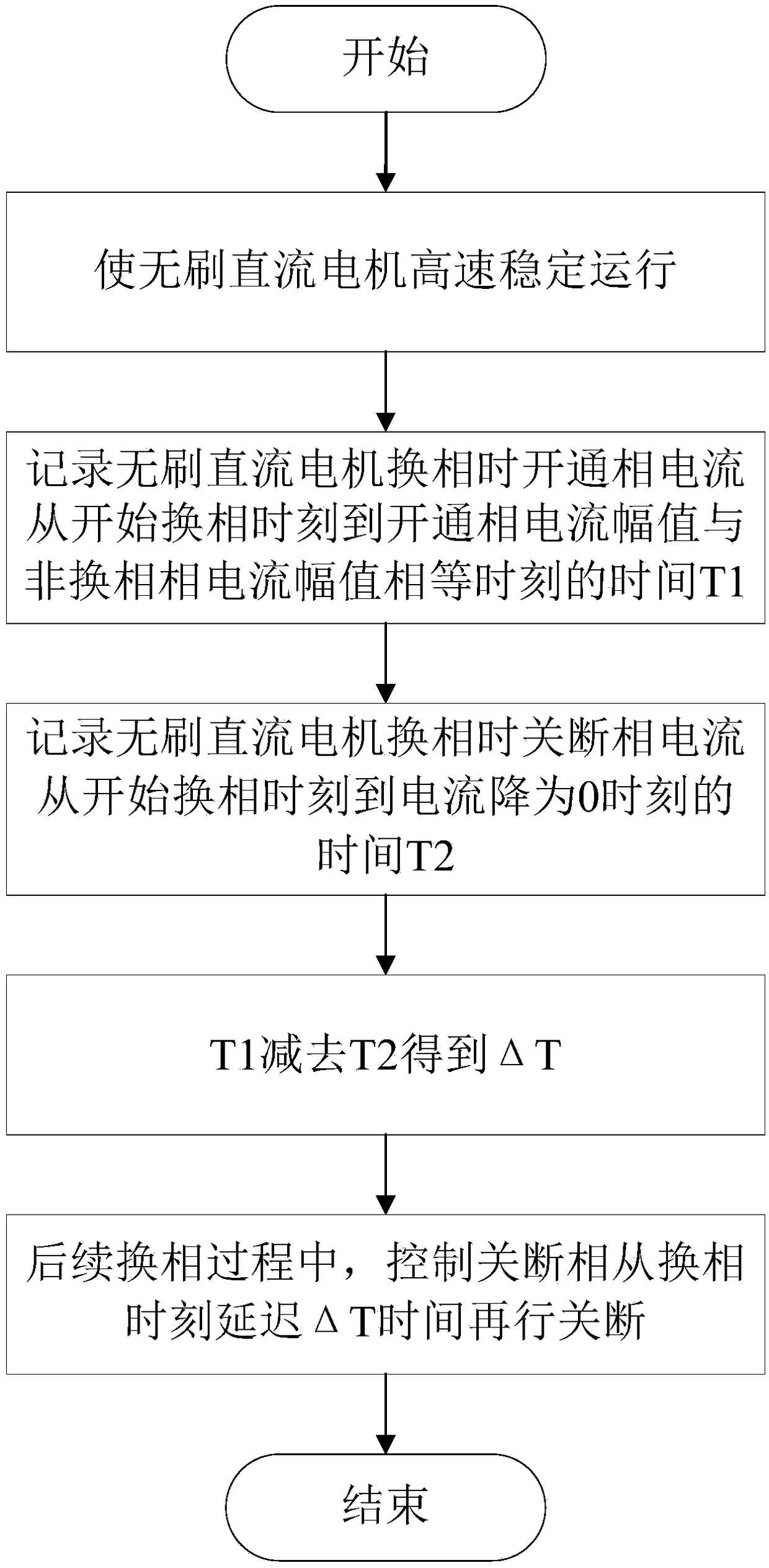

[0015] Such as figure 1 As shown, the present invention provides a method for controlling the delay time of a brushless DC motor shutdown phase, comprising the following steps:

[0016] Step 1. Make the brushless DC motor run stably at high speed;

[0017] Step 2. Determine the on-phase X, off-phase Y, and non-commutation phase Z of the brushless DC motor during the commutation process, and record the current of the on-phase X in the commutation process of the brushless DC motor from the beginning of commutation The interval time T1 between the moment and the moment when the current amplitude of the open phase X is equal to the current amplitude of the non-commutated phase Z;

[0018] Step 3. Record the interval time T2 between the current of the phase Y turned off during the commutation process of the brushless DC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com