A casting method for large corrosion-resistant aluminum-magnesium alloy components

An aluminum-magnesium alloy and corrosion-resistant technology is applied in the casting field of large-scale aluminum-magnesium alloy parts and components, which can solve the problems of difficult to control solidification structure, coarse solidification structure, shrinkage cavities, etc. Feeding effect, solving the effect of large wall thickness differential pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

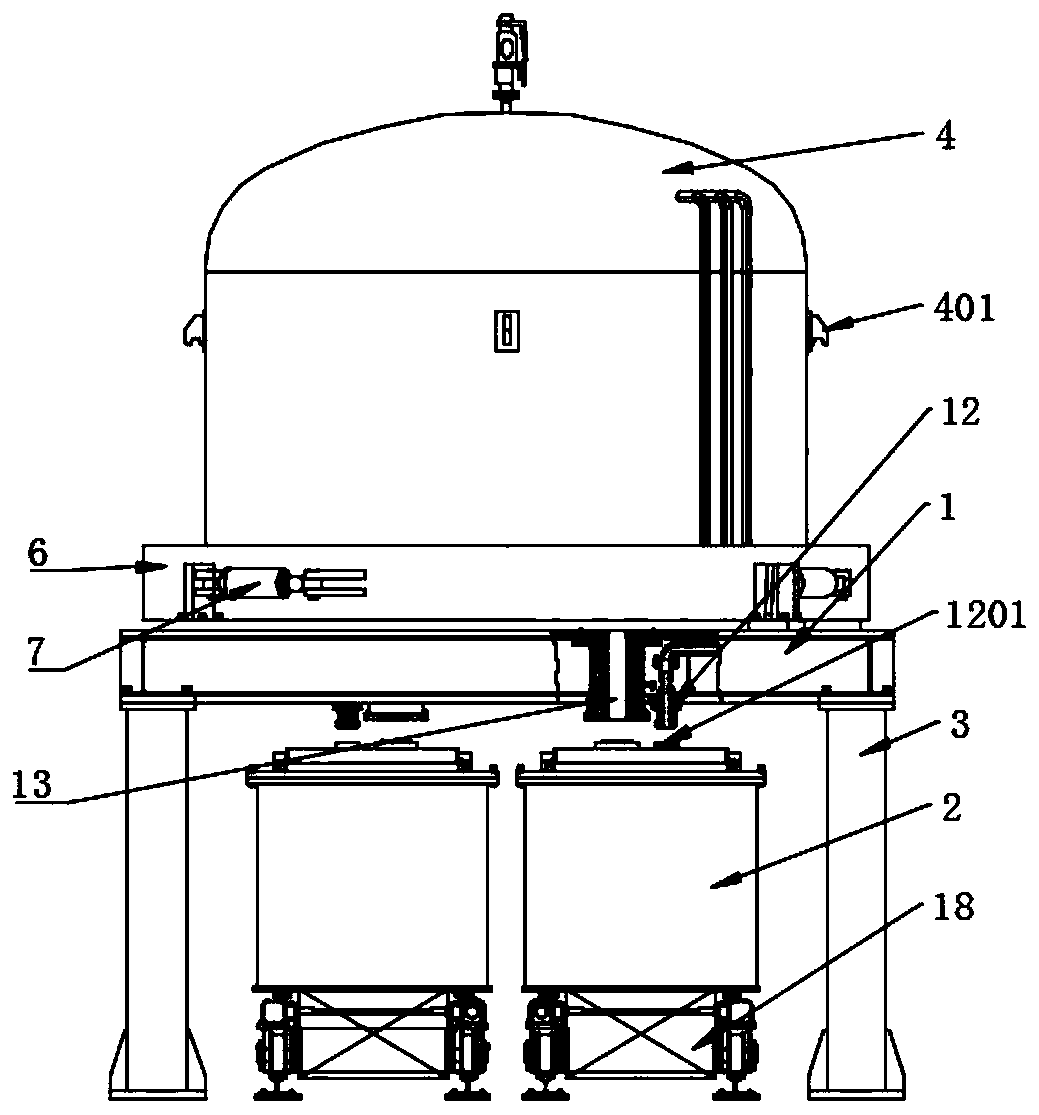

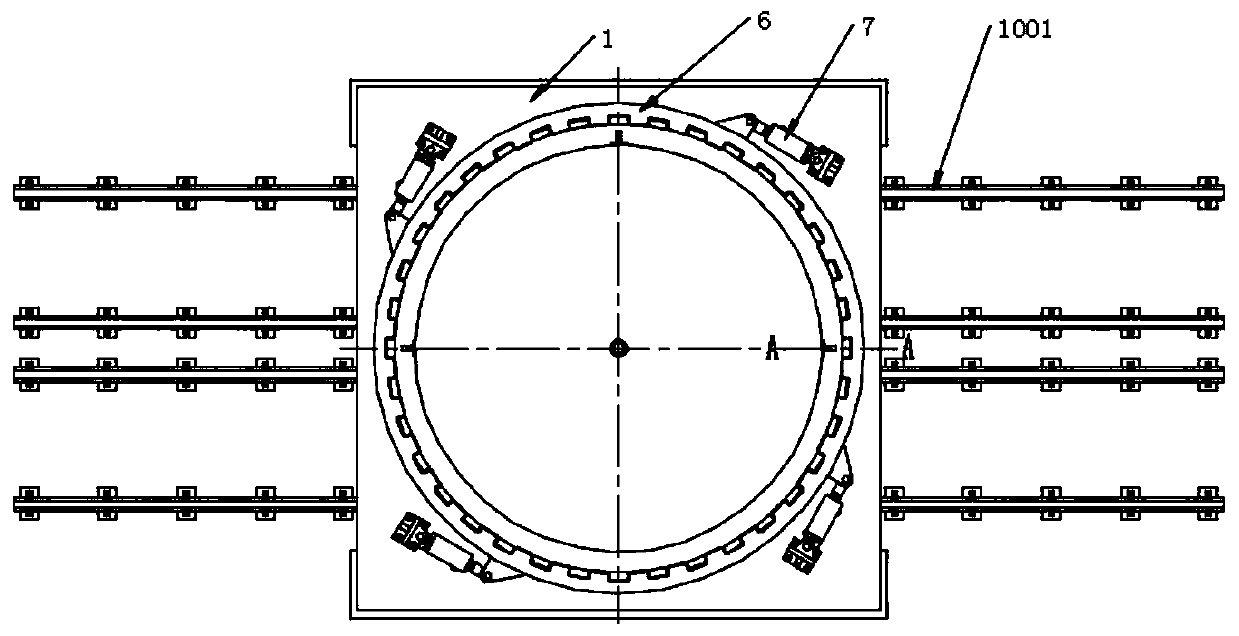

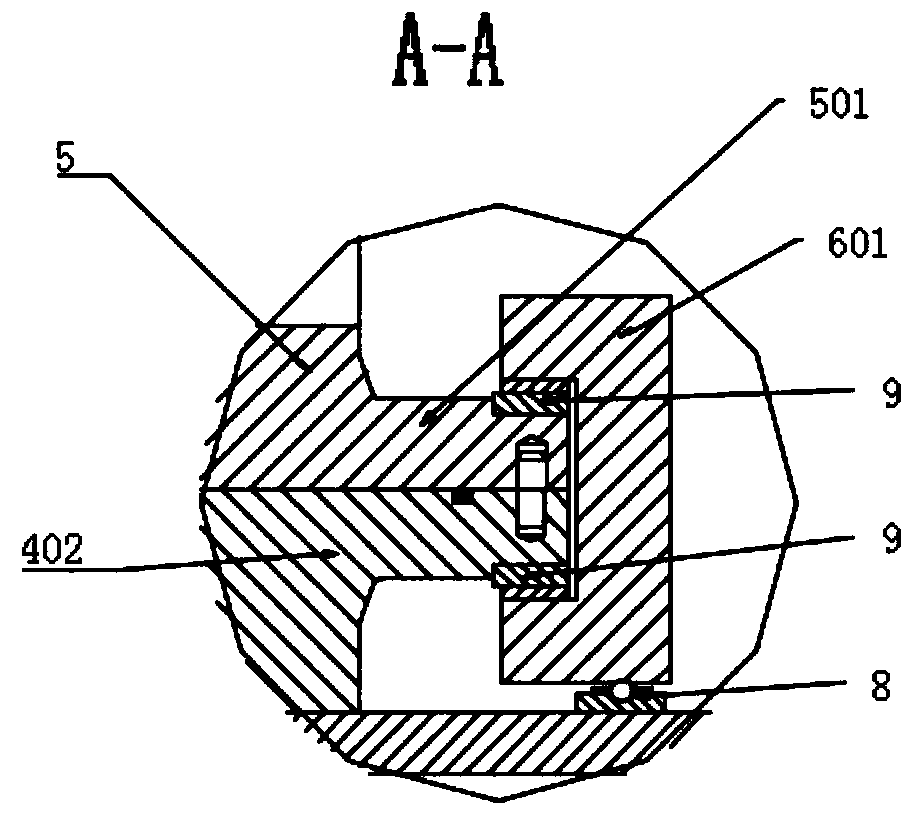

[0044] Embodiment 1: as Figure 1-9 As shown, this embodiment provides a multi-position parallel pressure casting device for large aluminum alloy castings, which is suitable for manufacturing large and complex parts in the fields of aerospace, ships, automobiles, electronics, etc., especially large and complex aluminum alloy castings. Castings such as alloy frames, plate shapes, and cabins can solve the problems of large pressure difference, unstable rising liquid, insufficient cold insulation and pouring, excessive pinhole and porosity, and serious hot cracking tendency existing in the manufacture of these large and complex castings. Oxidation, serious burning loss and other problems can improve the yield of castings.

[0045] Specifically, the casting device of this embodiment includes a platform 1, the top surface of the platform is a working surface, and a holding furnace 2 is arranged at the bottom of the platform. There are two or more holding furnaces, and each holding ...

Embodiment 2

[0080] Embodiment 2, according to the casting device of Embodiment 1, a large corrosion-resistant aluminum-magnesium alloy plate-shaped component is used as an application object, and a casting method for the large-scale corrosion-resistant aluminum-magnesium alloy plate-shaped component is provided. The specific details of the plate-shaped component Outline size: 2680mm×2314mm×165mm, main body wall thickness 15.0mm, weight 785kg, internal reinforcement ribs, plate-shaped structure, material: ZL301.

[0081] (1) Preparatory steps before pouring: Transport the refined 1500kg aluminum melt to four 800kg holding furnaces through the quantitative conveying device for use, the holding temperature is 680±5°C, and insert the riser pipe sprayed with 5mm thick refractory coating. Through the lifting system of the furnace body, the sealing between the gas inlet and outlet of the holding furnace, the synchronous sealing device and the upper and lower liquid riser pipes is completed, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com