An independent liquid level pressurization control system and method for a multi-position parallel pressurized casting device

A technology of pressure casting and liquid level pressurization, which is applied in the field of multi-position parallel pressure casting devices, can solve the problems of insufficient feeding capacity of casting process, large temperature difference between solid and liquid of paste solidified alloy, large surface tension of melt, etc. , to achieve the effect of eliminating dispersive shrinkage defects and improving local solidification and shrinkage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

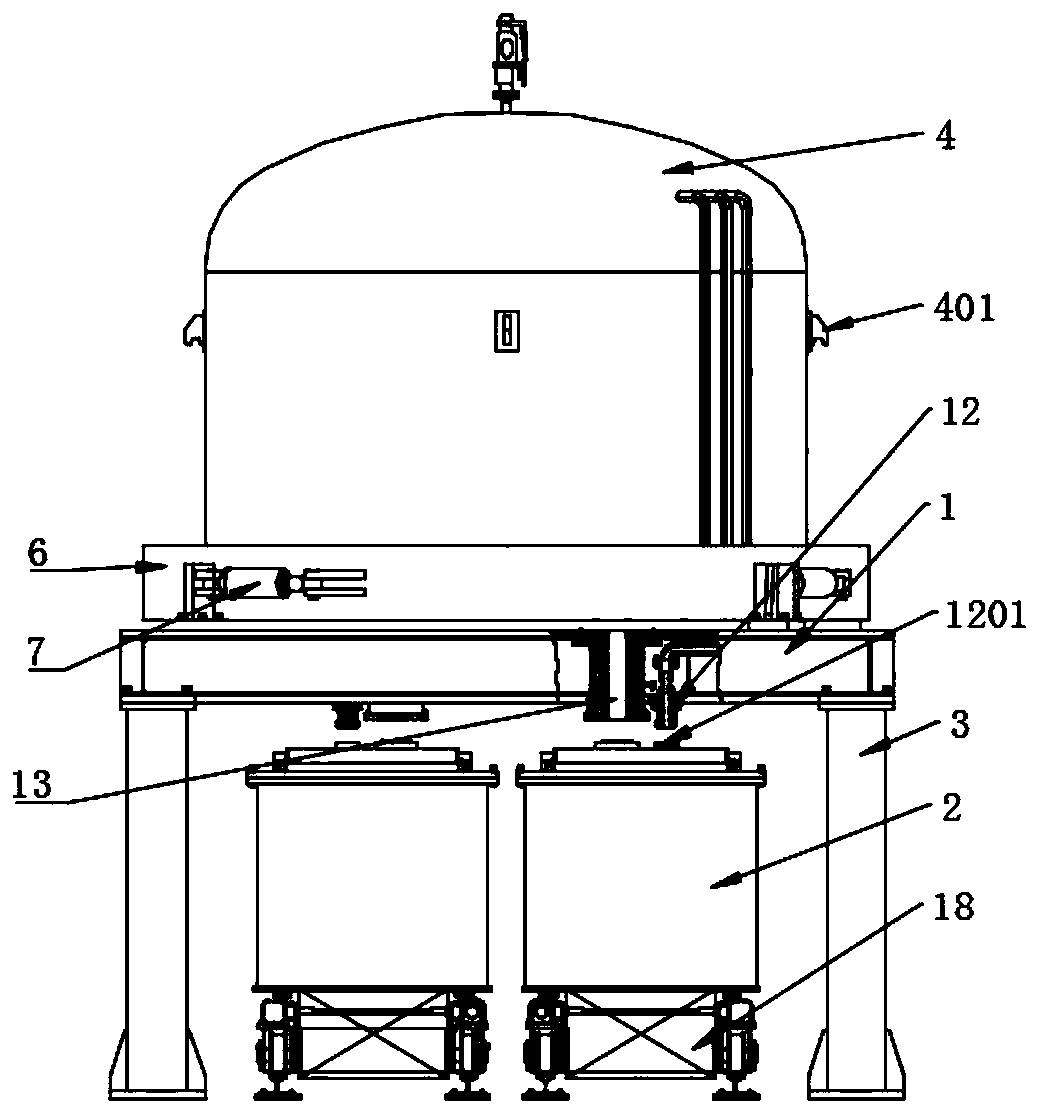

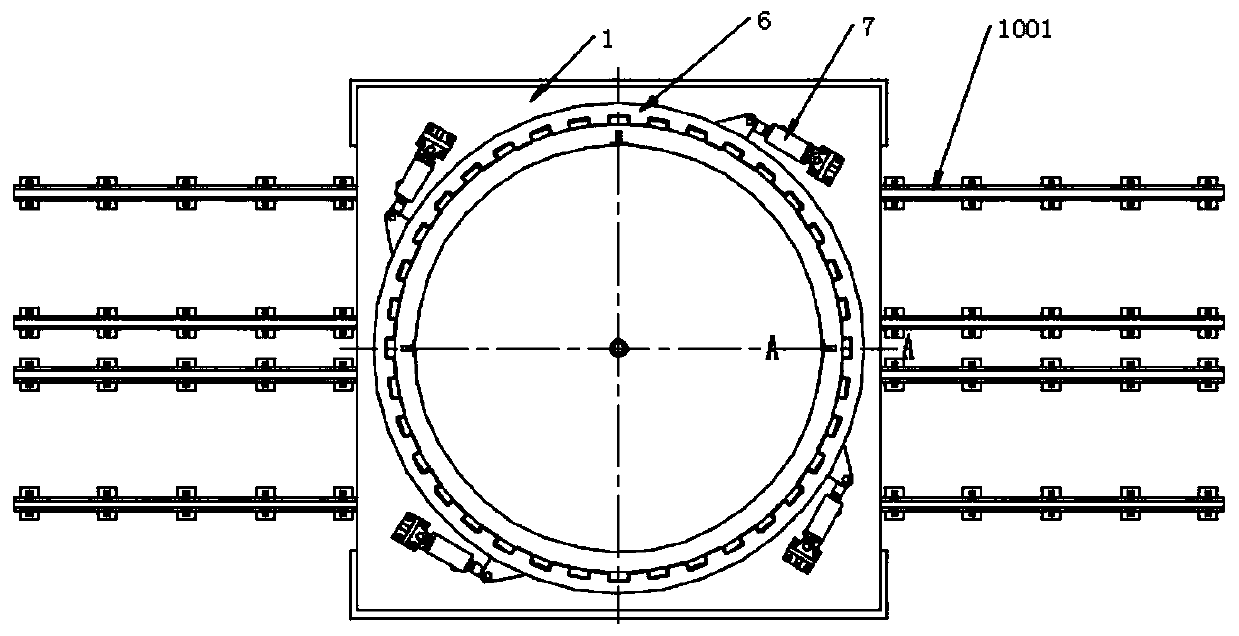

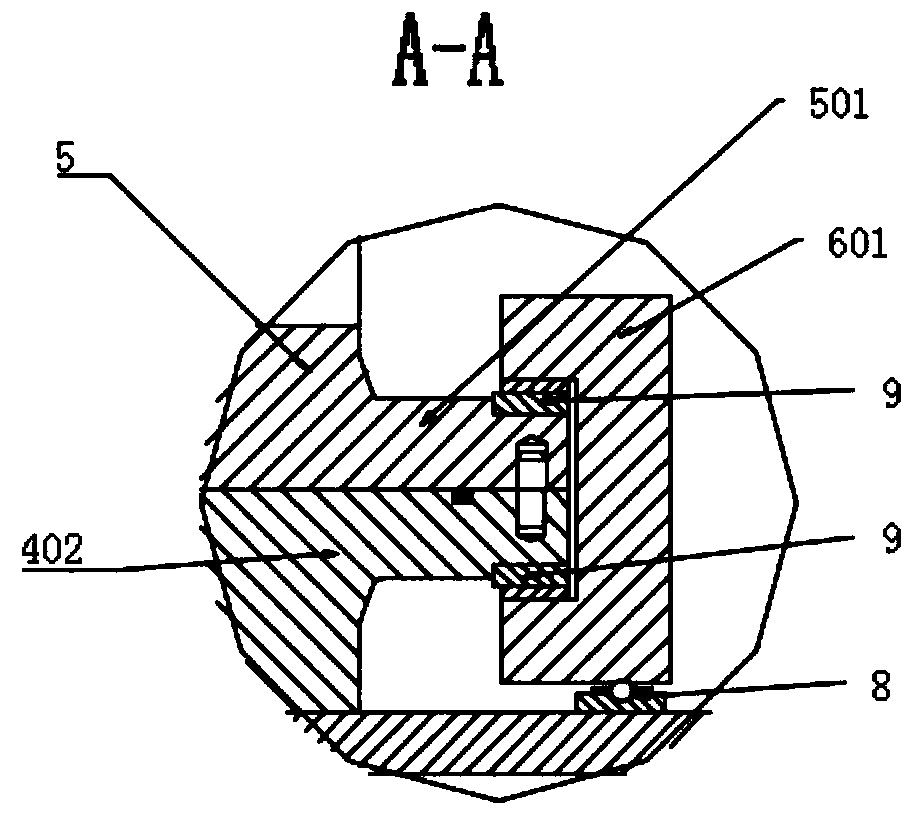

[0032] Embodiment 1: as Figure 1-9 As shown, this embodiment provides a multi-position parallel pressure casting device for large aluminum alloy castings, which is suitable for manufacturing large and complex castings in the fields of aerospace, weapons, ships, automobiles, electronics, etc., especially large and complex aluminum alloy castings. Castings such as alloy frames, plates, and cabins can solve the problems of turbulent flow, cold shut, insufficient pouring, excessive pinholes and porosity, and serious oxidation inclusions in the existing manufacturing of these large and complex castings, and improve the yield of castings.

[0033] Specifically, the casting device of this embodiment includes a platform 1, the top surface of the platform is a working surface, and a holding furnace 2 is arranged at the bottom of the platform. There are two or more holding furnaces, and each holding furnace is respectively It is connected to the corresponding liquid filling port on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com