Metal waste grinding and packing device

A waste and metal technology, applied in the field of metal waste rolling and packing device, can solve problems such as increasing cost and achieve the effect of solving the dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described in detail below in conjunction with the drawings and embodiments of the specification:

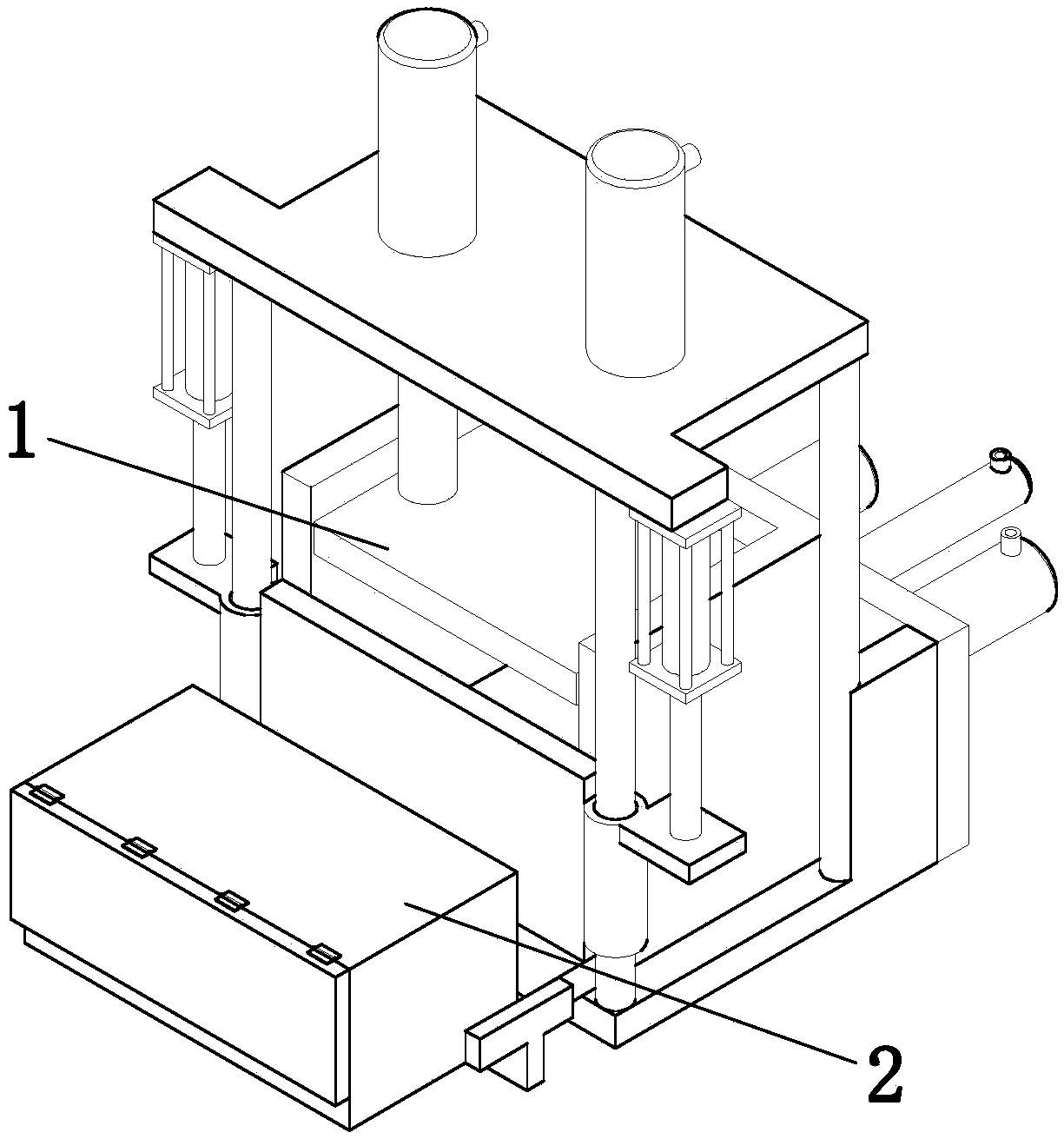

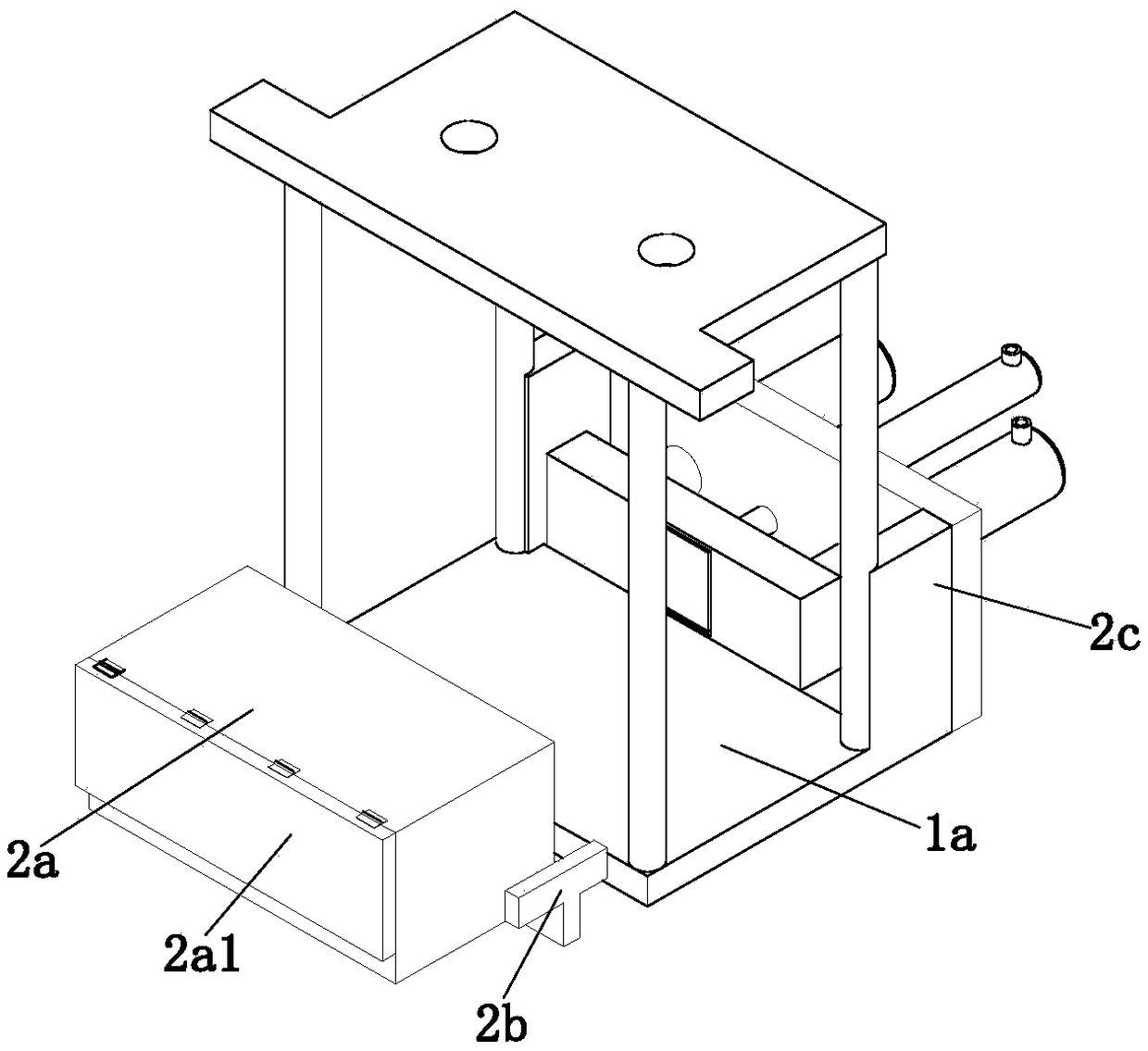

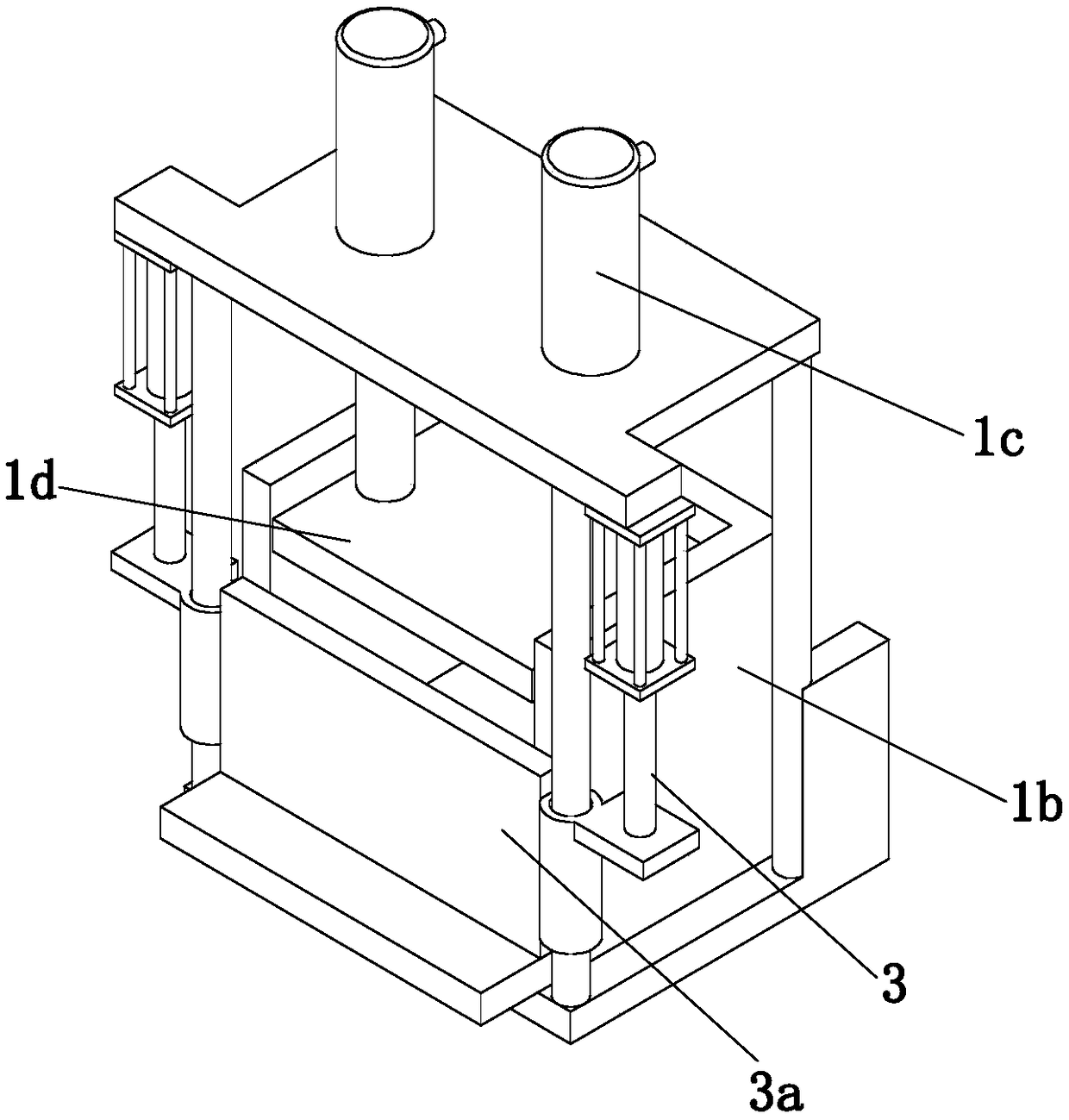

[0022] Reference Figure 1 to Figure 5 A metal waste rolling and packing device shown includes a rolling assembly 1 and a packing assembly 2. The rolling assembly 1 is vertically arranged at the upper end of the packing assembly 2. The rolling assembly 1 includes a frame 1a, The compaction box 1b and the rolling hydraulic press 1c, the compaction box 1b is set inside the frame 1a, the compaction hydraulic press 1c is installed vertically on the top of the frame 1a and the output end extends downward to the interior of the compaction box 1b. The output end is provided with a pressure plate 1d, the packing assembly 2 includes a packing box 2a, a packing slot 2b, and a packing hydraulic unit 2c. The two ends of the packing slot 2b are provided with connecting packing box 2a and rolling box 1b. The fixing plate 2b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap