Architectural-assembling transmission device

A technology of transmission device and transmission rod, which is applied in the direction of transportation and packaging, loading/unloading, and vehicles with wheels, etc., which can solve the problems of adjustment, lack of safety protection ability of prefabricated buildings, difficulty in regular cleaning and regular maintenance, etc., and achieve improvement The effect of protective ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

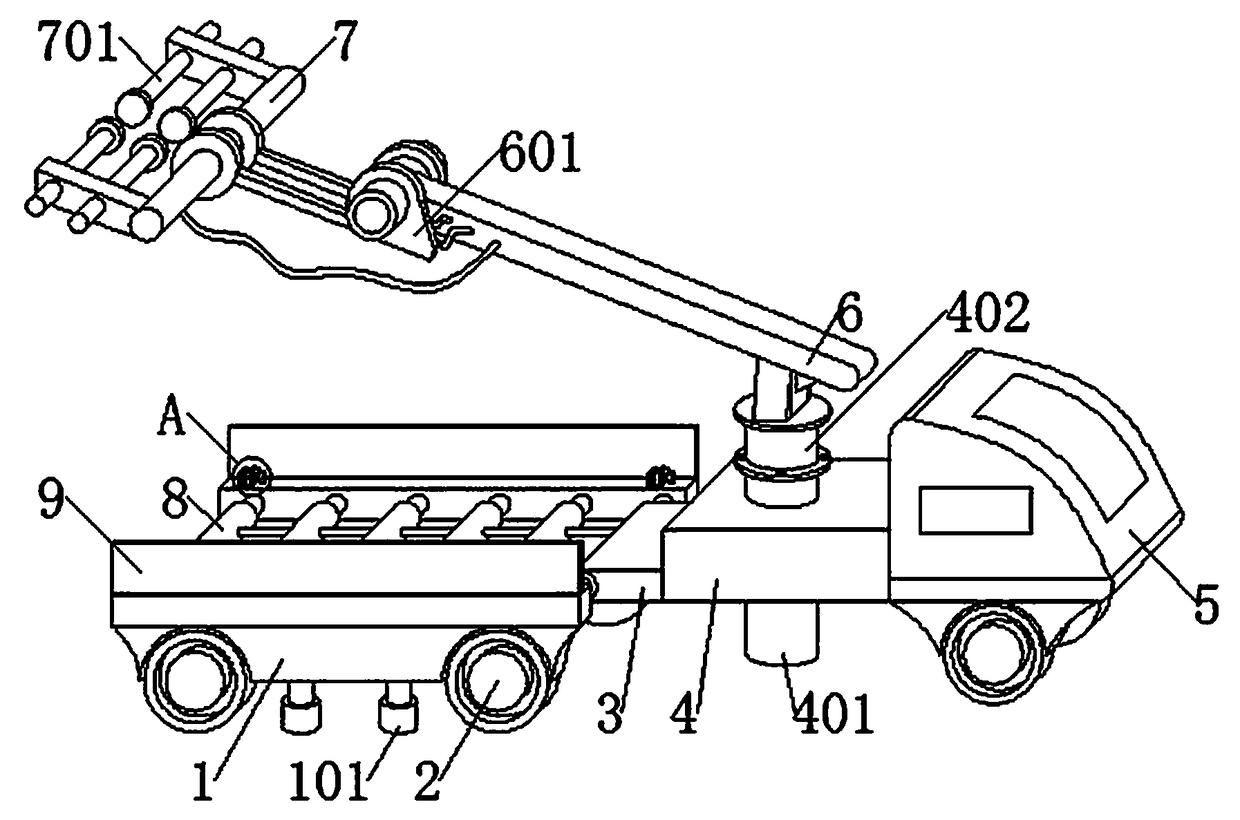

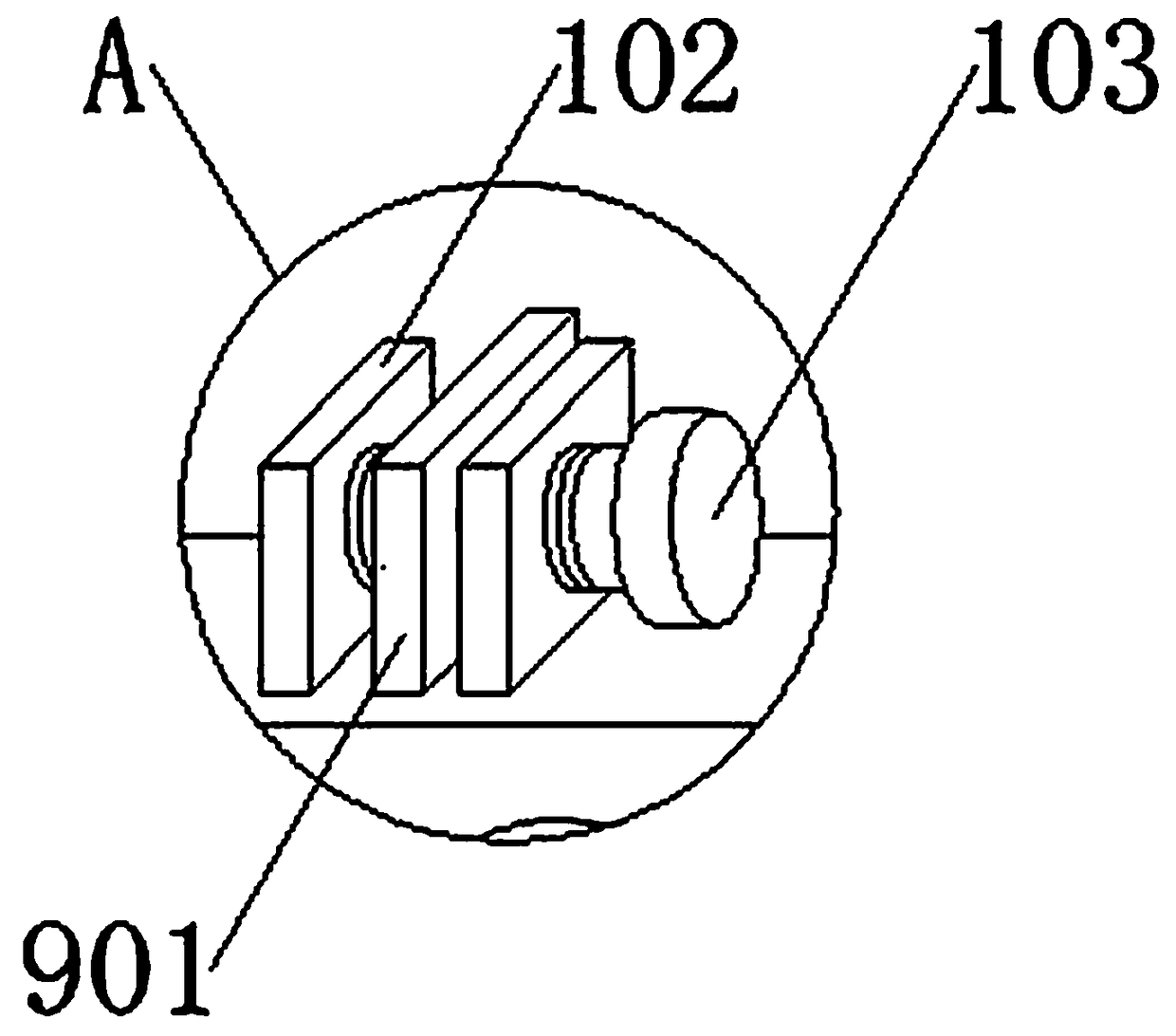

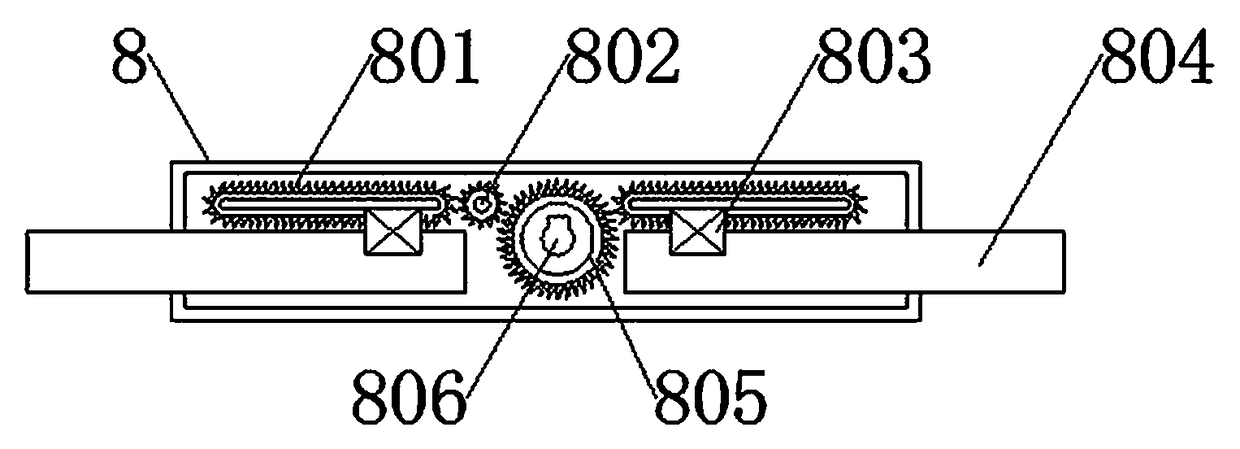

[0025] See Figure 1-4 , The present invention provides a technical solution: a construction assembly transmission device, including a frame 1, a work board 4, a control room 5, a transmission rod 6 and a rigid straight tube 8, the frame 1 and the bottom end of the control room 5 are clamped There are six wheels 2, and the six wheels 2 are evenly and symmetrically distributed. Four jacks 101 are arranged at the bottom end of the frame 1 close to the wheels 2, and the four jacks 101 are evenly and symmetrically distributed. The top of the frame 1 is movably connected with two Four pairs of frame plates 102 are welded on the top of the frame 1 close to the frame 9, and the four pairs of frame plates 102 are evenly and symmetrically distributed. One end of the four pairs of frame plates 102 is bolted with a screw 103, which is close to the four pairs of frame plates. Four plate connecting blocks 901 are welded to the side of the machine board 9 of the frame plate 102, and the plat...

Embodiment 2

[0027] In an embodiment, a construction assembly transmission device includes a frame 1, a working plate 4, a control room 5, a transmission rod 6 and a rigid straight tube 8. The bottom ends of the frame 1 and the control room 5 are clamped with six wheels 2 , And the six wheels 2 are evenly and symmetrically distributed. Four jacks 101 are arranged at the bottom of the frame 1 close to the wheels 2, and the four jacks 101 are evenly and symmetrically distributed. The top of the frame 1 is movably connected with two symmetrical machines. Plate 9, the top of the frame 1 close to the machine plate 9 is welded with four pairs of frame plates 102, and the four pairs of frame plates 102 are evenly and symmetrically distributed. One end of the four pairs of frame plates 102 is bolted with a screw 103, which is close to the four pairs of frame plates 102 There are four plate connecting blocks 901 welded on one side of the machine board 9, and the plate connecting block 901 and the cor...

Embodiment 3

[0030] In an embodiment, a construction assembly transmission device includes a frame 1, a working plate 4, a control room 5, a transmission rod 6 and a rigid straight tube 8. The bottom ends of the frame 1 and the control room 5 are clamped with six wheels 2 , And the six wheels 2 are evenly and symmetrically distributed. Four jacks 101 are arranged at the bottom of the frame 1 close to the wheels 2, and the four jacks 101 are evenly and symmetrically distributed. The top of the frame 1 is movably connected with two symmetrical machines. Plate 9, the top of the frame 1 close to the machine plate 9 is welded with four pairs of frame plates 102, and the four pairs of frame plates 102 are evenly and symmetrically distributed. One end of the four pairs of frame plates 102 is bolted with a screw 103, which is close to the four pairs of frame plates 102 There are four plate connecting blocks 901 welded on one side of the machine board 9, and the plate connecting block 901 and the cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com