Constraint damping rail with phi-type expanded layer

A technology of restraining damping and expanding layers, applied in the field of damping rails, can solve problems such as adverse effects on physical and mental health, reduce passenger comfort and stability, and achieve the effect of improving the effect of vibration reduction and noise reduction, and strengthening the shear effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

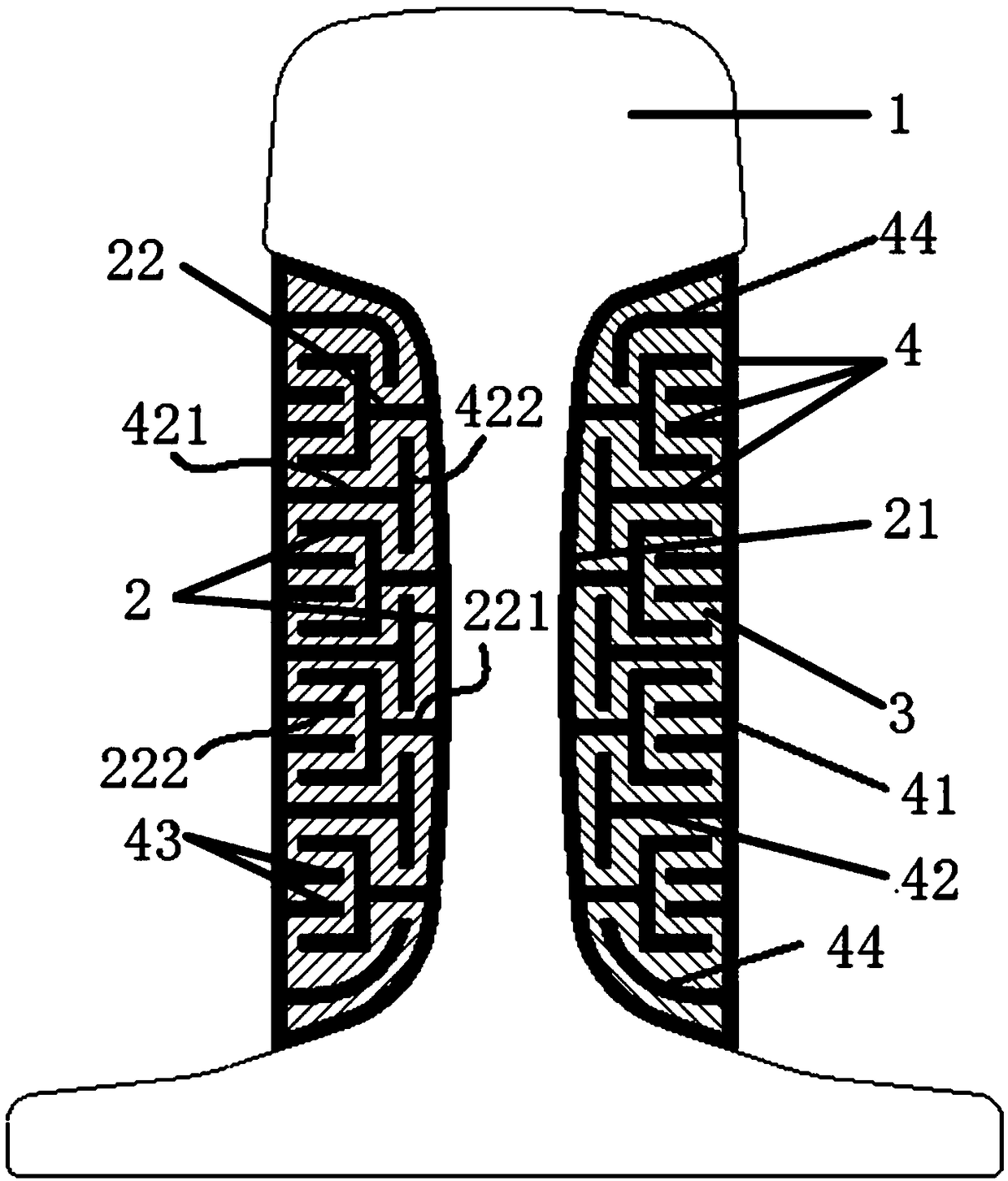

[0025] a belt Type expansion layer constrained damping rails, such as figure 1 As shown, including rail body 1, Type expansion layer 2, constraint layer 4 and damping filling layer 3, where:

[0026] The type expansion layer 2 consists of an expansion layer base layer 21 pasted on the non-working surface at the rail waist and rail top of the rail body 1 and a plurality of expansion layer base layers 21 extending outward from the expansion layer base layer 21. Type expansion slot 22;

[0027] Constraint Layer 4 consists of a set of The constrained layer outer layer 41 on the periphery of the type expansion layer 2, a plurality of long T-shaped structural members 42 extending from the constrained layer outer layer 41 to the rail waist, and multiple sets of double short transverse plate structural members 43, each set of double short transverse plate 43 and Type expansion slots 22 are matched and extended into In the type expansion slot 22, the long T-shaped structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com