Double-T staggered constrained damping rail

A constrained damping and staggered technology, applied in the field of damping rails, can solve the problems of reducing the comfort of passengers in the car, and achieve the effects of improving vibration and noise reduction, increasing the shear area, and strengthening the shear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

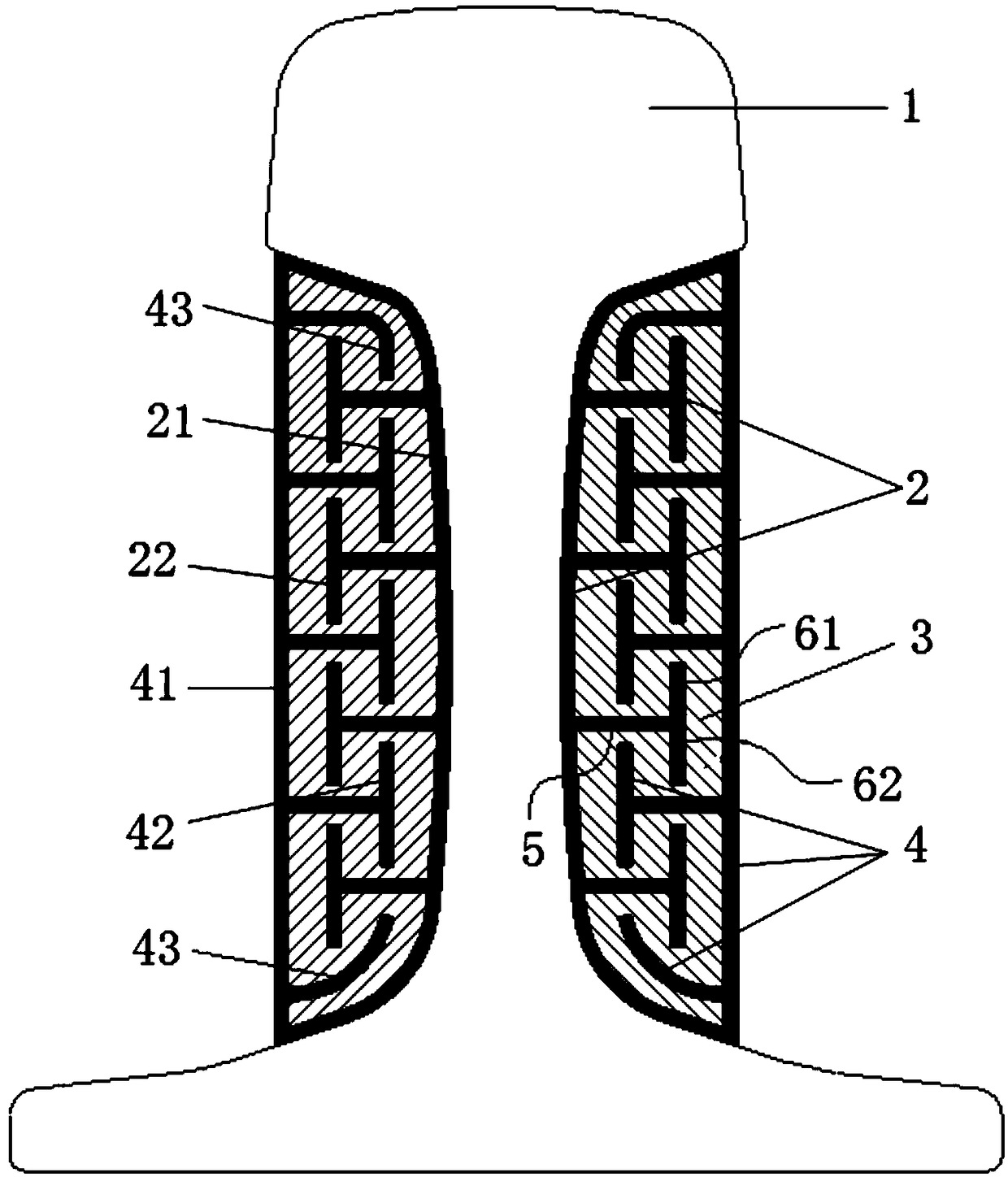

[0024] A kind of double T staggered restrained damping steel rail figure 1 (Shown), including the rail body 1, the T-shaped expansion layer 2, the T-shaped constraining layer 4, and the damping filling layer 3.

[0025] The T-shaped expansion layer 2 is composed of an expansion layer base layer 21 that fits the rail waist and the non-working surface of the rail top of the rail body 1, and a plurality of T-shaped expansion grooves 22 extending outward from the expansion layer base layer 21;

[0026] The T-shaped constrained layer 4 includes a constrained layer outer layer 41 arranged on the periphery of the T-shaped expansion layer 2 and a plurality of T-shaped structural members 42 extending from the constrained layer outer layer 41 to the rail waist, a T-shaped expansion slot 22 and a T-shaped structure The pieces 42 are arranged in a staggered arrangement;

[0027] The damping filling layer 3 is filled in the gap between the T-shaped expansion layer 2 and the T-shaped constraining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com